English

7 / 8

ICEP007-024 (60Hz)

4. Press the button “

set

” to see the alarm code.

5. Press the button “

” to see the next code.

6. Press the button “

esc

” to exit

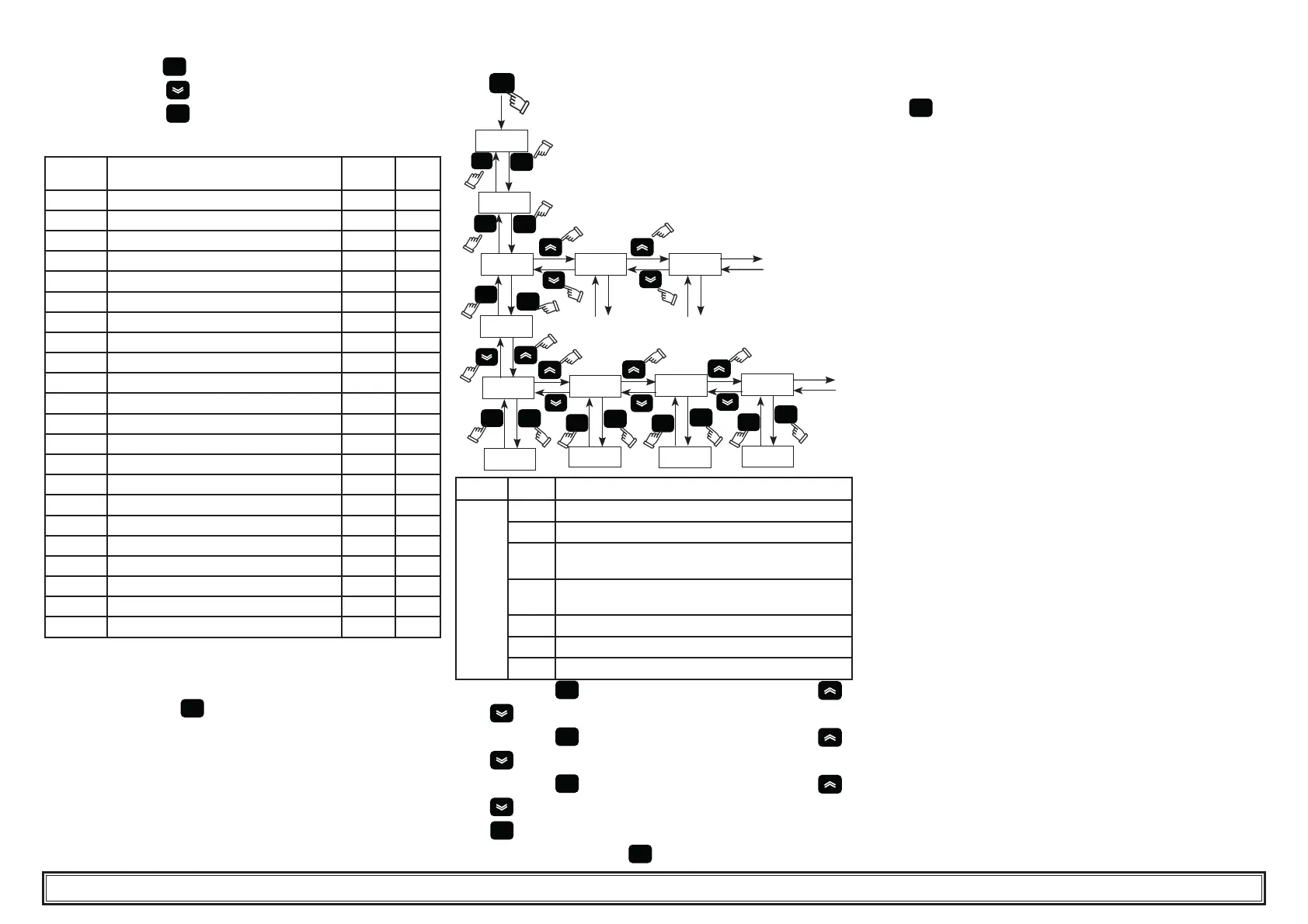

4.8.1 Analog /Digital input alarms

CODICE DESCRIZIONE AZIONE RE-

SET

Er01

Sensor B1 cutout or broken Alarm A

Er02

Sensor B2 cutout or broken Alarm A

Er03

Sensor B3 cutout or broken Alarm A

Er04

High pressure Alarm M

Er05

Low pressure Alarm M

Er06

Pump thermal cutout Alarm M

Er07

Low water level Alarm M

Er08

High pressure trasducer cutout or broken Alarm A

Er10

Sensor B4 cutout or broken Warning M

Er12

Compressor thermal * Alarm M

Er14

High temperature sensor B1 Alarm A

Er15

Low temperature sensor B1 Alarm A

Er16

High temperature sensor B2 Alarm A

Er17

Low temperature sensor B2 Alarm A

Er18

High temperature sensor B3 Alarm A

Er19

Low temperature sensor B3 Alarm A

Er20

Antifreeze Alarm A

Er21

Exceeded compressor working hours Warning A

Er23

Phase monitor Alarm M

Er24

Exceeded unit working hours Warning A

Er25

Communication expansion Alarm A

Er26

Controller memory Warning A

* ! (Only oil model)

If the evaporator temperature falls below 5°C for more than 120s

then an alarm “

Er12 “ will occur, blocking the unit.

!Press the button “

esc

” to reset alarms (5sec).

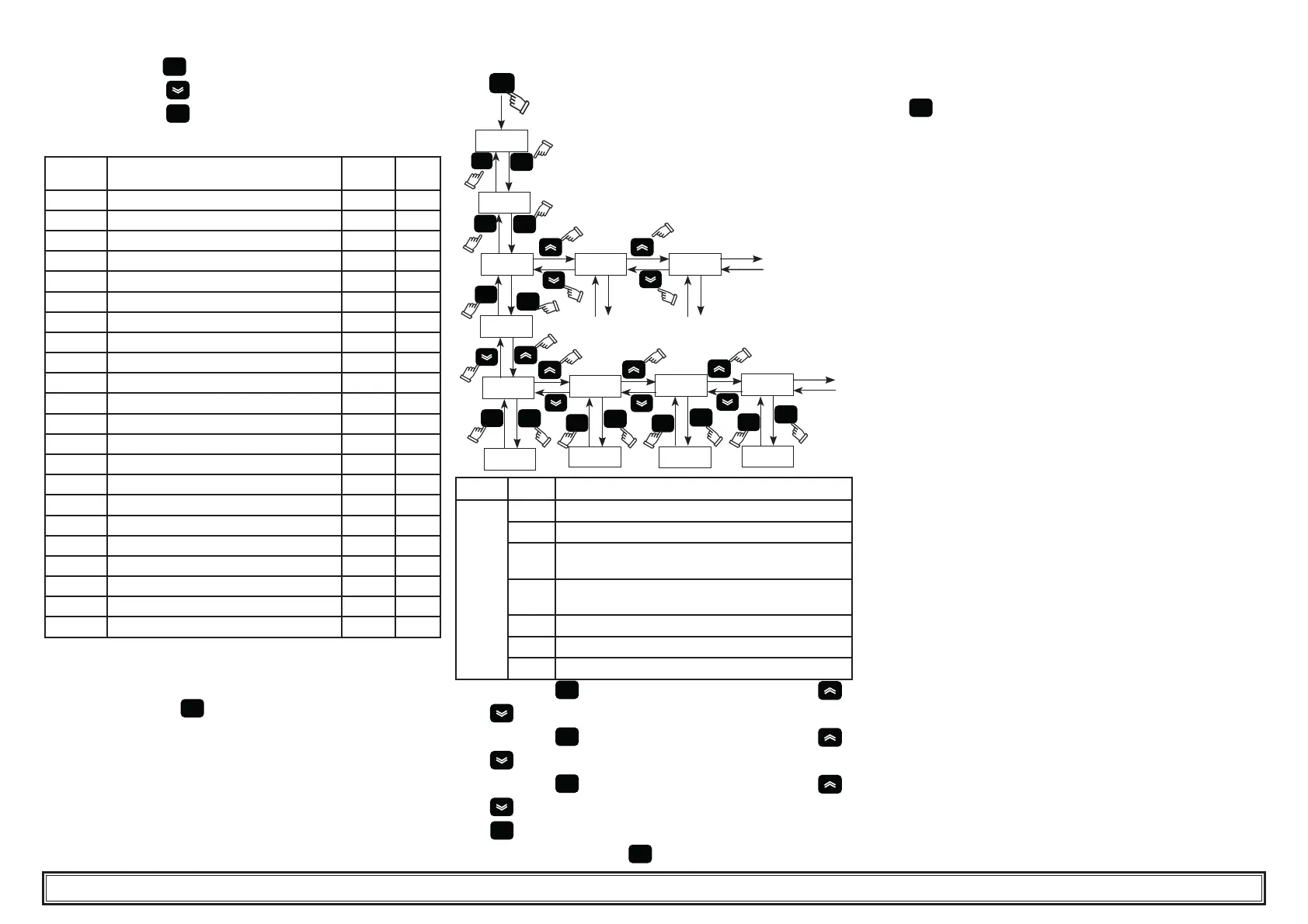

4.9 Alarm/Warning history

ALHi

HySP

esc

set

esc

set

0

1 2

set

HySP

HySC

04

18.06

HySd

HySt

13.46

HyS1

28

set

esc

esc

set

esc

set

esc

set

esc

set

Menu Code DESCRIPTION

ALHi

HySP Alarm number

HySC See alarm code

HySd

See day and month of the alarm

(if the clock option is present)

HySt

See hour and minutes of the alarm

(if the clock option is present)

HyS1 b1 temperature at time of the alarm

HyS2 b2 temperature at time of the alarm

HyS3

SET conditions at time of the alarm

Press the button “

set

” to enter in the menu, using the buttons “

”and “ ” select the parameter “ ALHi”.

Press the button “

set

” to enter in the menu, using the buttons “

”and “ ” select the parameter “HySP”.

Press the button “

set

” to enter in the menu, using the buttons “

”and “ ” select the alarm number insert (0,1,2......39) and con rm

with “

set

” (the number 0 is the last alarm started) .

“HySP” appears again, press “

set

” to enter and see the date of the

alarm: “HySC” code (es:HP), “HySd” Date (day, month), “HySt” hour

(hour, minutes), “HyS1” “HyS2” “HyS3” sensor b1, b2 and set when the

alarm occurred.

Press “

esc

” to exit.

4.10 Automatic restart

In the event of a power failure, when power is restored the chiller will

assume the On-Off status held at the moment the power was lost.

5 MaintenanceMaintenance

a) The machine is designed and built to guarantee continuous operaa)

The machine is designed and built to guarantee continuous opera-

tion; however, the life of its components depends on the mainte-

nance performed.

b) When requesting assistance or spare parts, identify the machine

(model and serial number) by reading the dataplate located on the

unit.

5.1 General instructions

! Before performing any maintenance, make sure the power to the

refrigerator is disconnected.

Y Always use the Manufacturer’s original spare parts: otherwise the

Manufacturer is relieved of all liability regarding machine malfunction-

ing.

Y In case of refrigerant leakage, contact quali ed and authorized

personnel.

Y The Schrader valve must only be used in case of machine mal-

function: otherwise any damage caused by incorrect refrigerant charg-

ing will not be covered by the warranty.

5.2 Preventive maintenance

To guarantee lasting maximum chiller ef ciency and reliability, carry out:

a)

Z every 6 months - clean the condenser ns and make sure

compressor electrical absorption is within the dataplate values;

b)

Z kit for maintenance (par.7.5)

• kit for maintenance;

• service kit;

• individual spare parts.

Loading...

Loading...