12 – English

SET UP AND ADJUSTMENTS

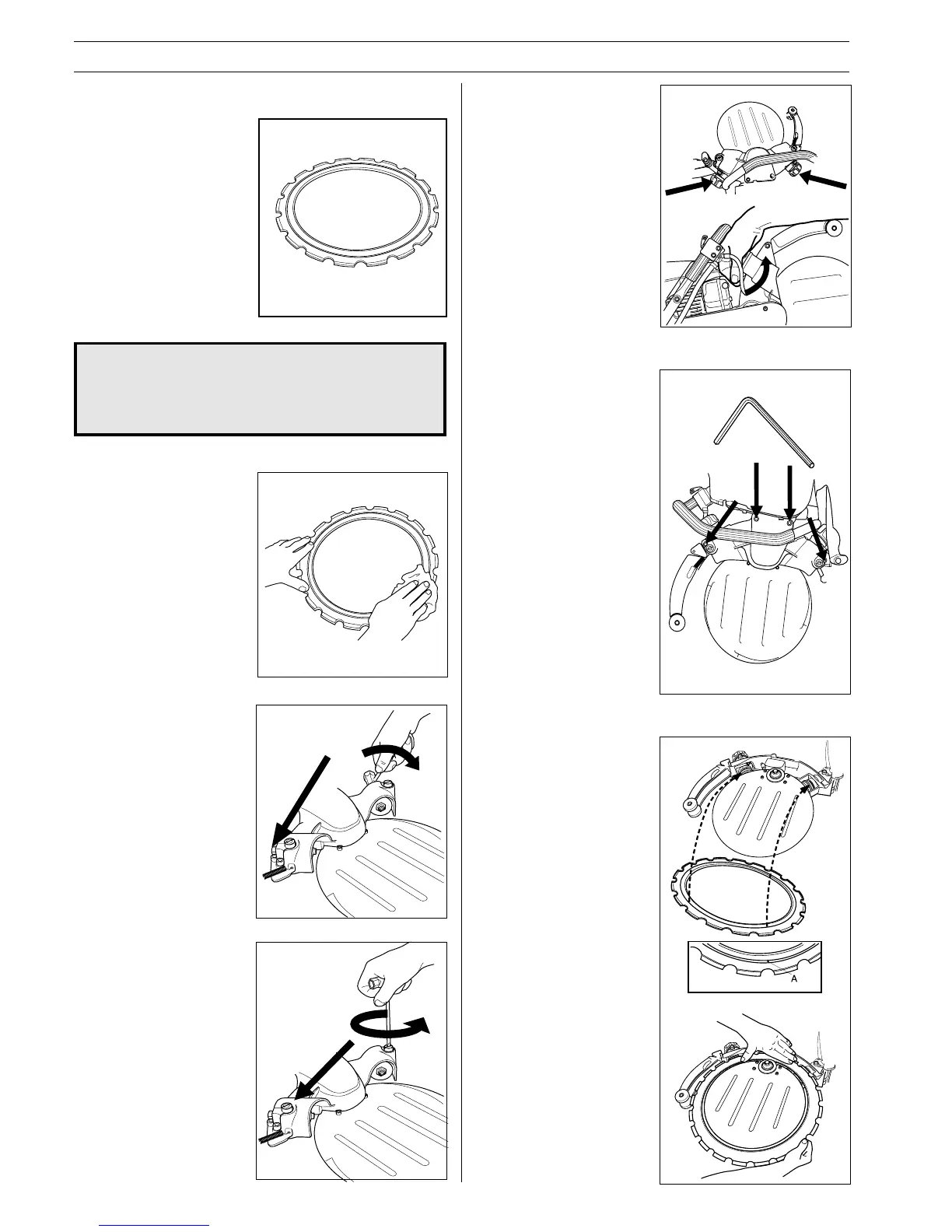

NOTE: Partner offers a

selection of wet cutting ring

blades for different materials.

Check with a Partner dealer

for the blade that is best

suited for your application.

WARNING!

Never retip a used ring blade. A used blade

may not have the proper strength. A retipped

blade may crack or break and cause severe

personal injury to the operator or others.

• Wipe blade to remove any

debris from the blade

surface.

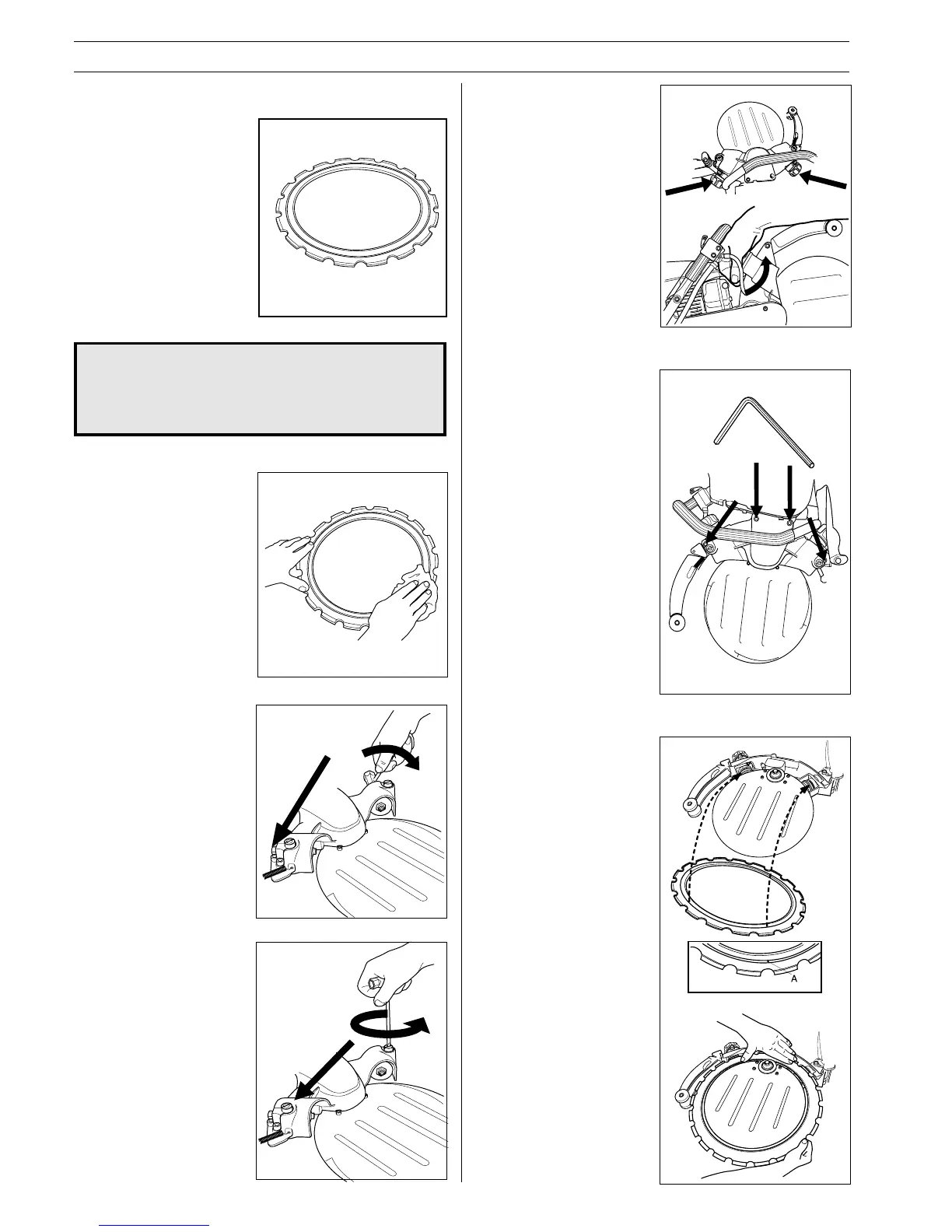

• Loosen the locknuts on the

support roller cover.

!

• Unscrew the adjusting

screws a few turns.

• Loosen the knobs to release

all spring tension.

• Remove the four screws

that fasten the support roller

cover with the 6 mm L-allen

wrench and remove the

cover.

• Put the blade on the

machine.

• Next, insert the blade into

the drive disc. Rotate the

blade while installing it onto

the lower engagement

roller. If needed, push in

the engagement rollers, so

that the shoulders on the

engagement rollers enters

the groove on the blade.

NOTE: The blade has a

machined groove on one

side which is the tracking

groove for the engagement

rollers.

Blade Installation

Loading...

Loading...