www.parweld.com

6

Read and follow instrucons on compressed gas

cylinders, associated equipment, and Compressed Gas

Associaon (CGA)

2.0 Product Descripon

The XTM 353SW and 403SW are complete

semiautomac constant voltage DC arc welding

machines built to meet CE specicaons. They

combine a constant voltage power source and a

constant speed wire feeder with a microcomputer-

based controller to form a reliable high-performance

welding system. A simple control scheme, consisng

of a range voltage and wire feed speed controls,

provides versality with ease of use and accuracy.

The machines also include built in water cooling and

recirculaon units to allow the use of water cooled

torches. Other features include separate wire feed

unit for remote operaon, an integral gas cylinder

mounng undercarriage, an adjustable Argon ow

regulator with cylinder pressure gauge and inlet

hose, a Parweld MIG torch, and a 3.0m work cable

with clamp. Digital meters display the actual welding

voltage and amperage and the machine has addional

controls for adjustment of burn back and so starng.

3.0 Technical Specicaons

The XTM353SW and 403SW are a separate type

machine with the wire feed unit connected to the

power supply but a 5m interconnecng cable for use

with 3 phase 400V supply.

Feature XTM353SW XTM403SW

Input voltage 400V +/-10% 400V +/-10%

Hz 50 50

Phases 3 3

Current Draw (A) 17.2 18

Fuse rang (A) 18 28

Output current

(A)

60-300 60-400

OCV 18-36 20-45

Load voltage 17-29 17-34

Feed speed m/

min

0.8-24 0.8-24

Feed motor 42V 42V

Wire drive 4 roll 4 roll

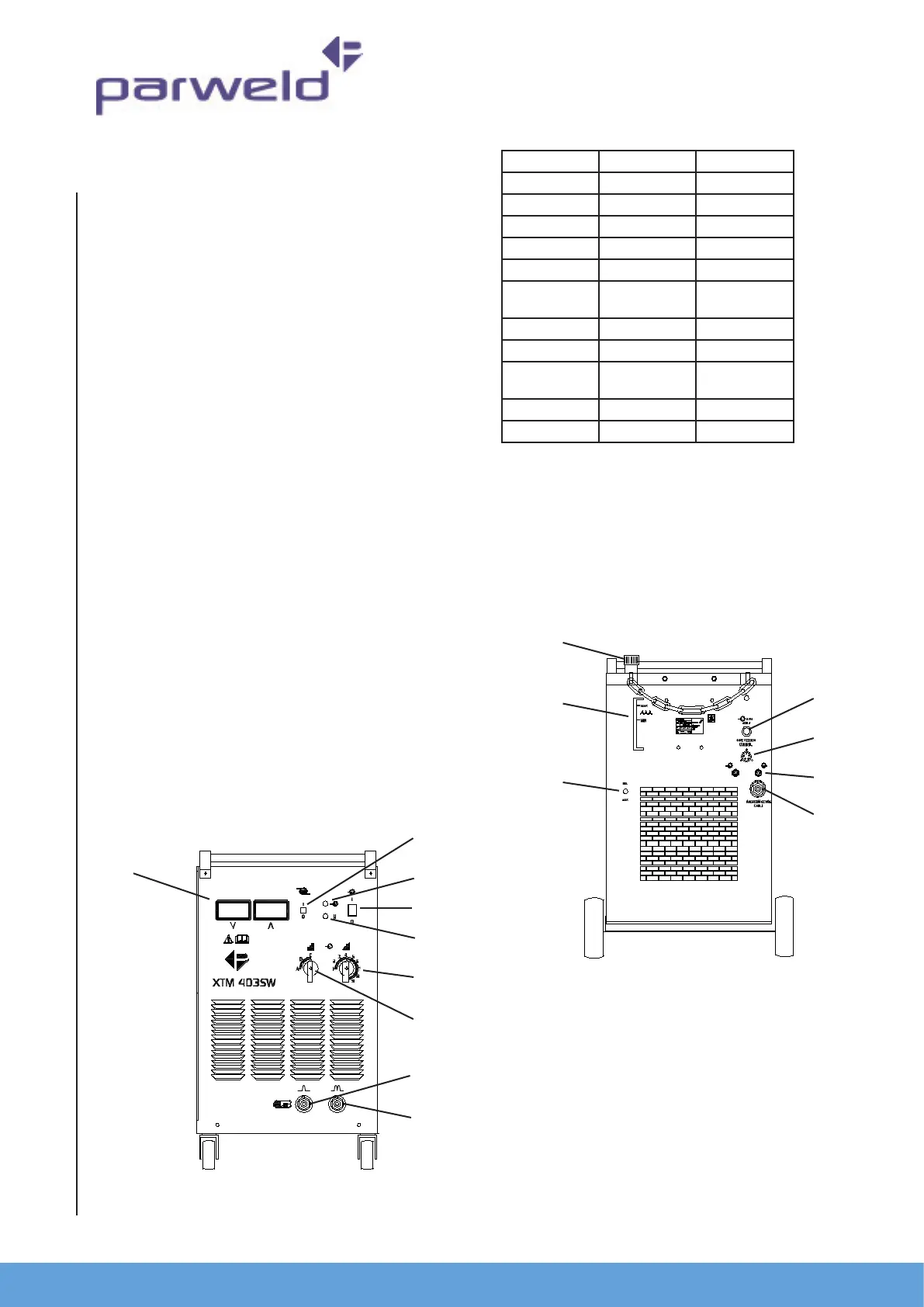

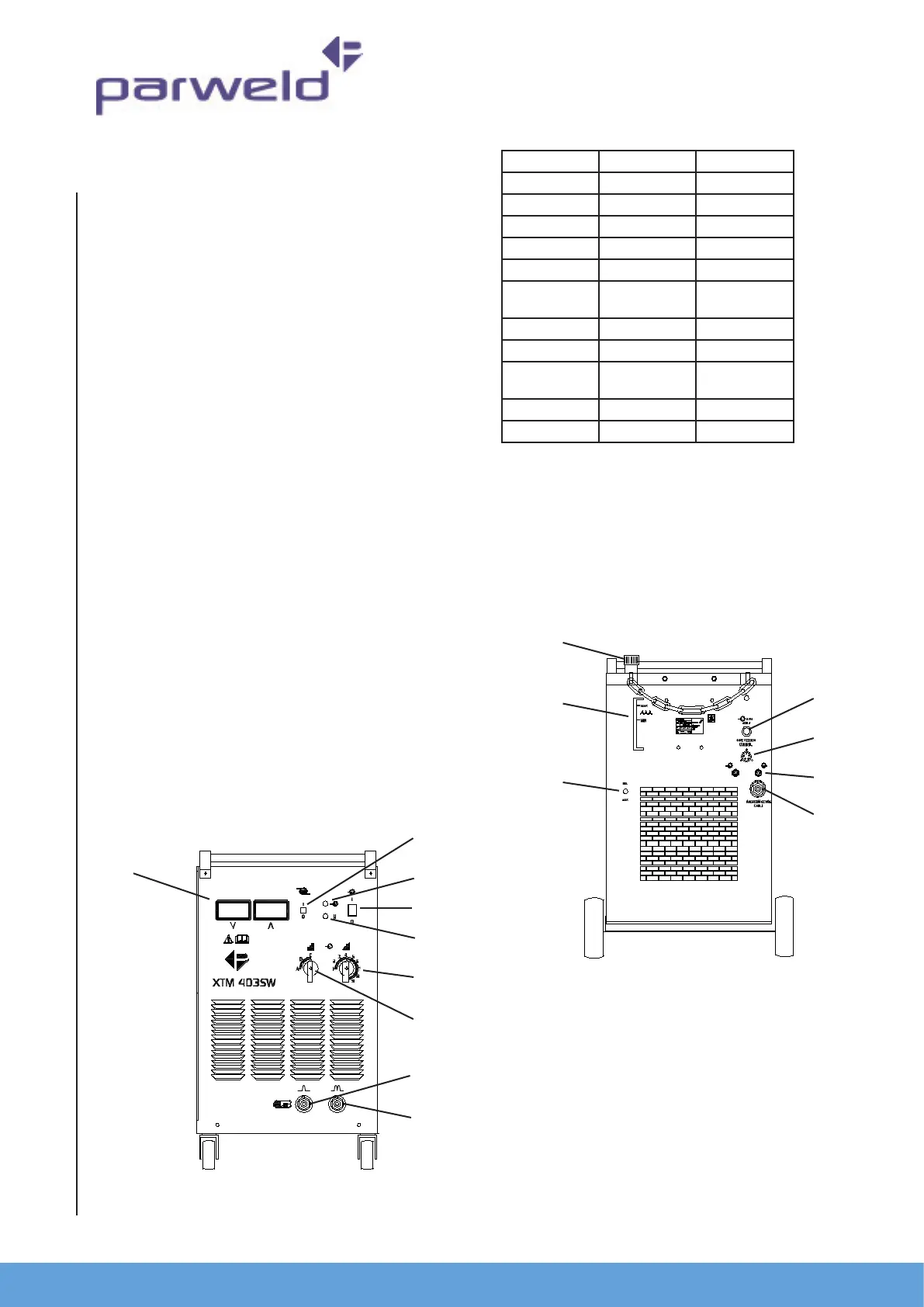

4.0 Descripon of controls

1. Digital display for amperage and Voltage

(displayed real me)

2. Water cooler selector switch. This allows the

water recirculaon pump and the ow switch

to be disabled when an Air cooled torch is

connected.

3. Mains input light This light illuminates when the

mains power is connected and the machine is

switched on.

4. On O switch. The machine is switched o when

the light (4) is o and the fan is not running.

5. Fault light This light will illuminate when a fault or

over temperature condion has occurred. If this

light illuminates allow the machine to cool with

the fan sll running unl it exnguished. If the

light does not go o when the power source has

cooled down then have the machine checked by a

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Loading...

Loading...