www.parweld.com

7

qualied engineer.

6. Fine Voltage selector switch. This switch is used to

select the require welding voltage each posion of

the switch represents approximately 0.5V. Do Not

operate this switch while welding

7. Coarse Voltage selector switch. This switch is used

to select the require welding voltage each posion

of the switch represents approximately 4V. Do Not

operate this switch while welding

8. Work return lead connecon. This socket allows

connecon of the work return lead to the front of

the machine.

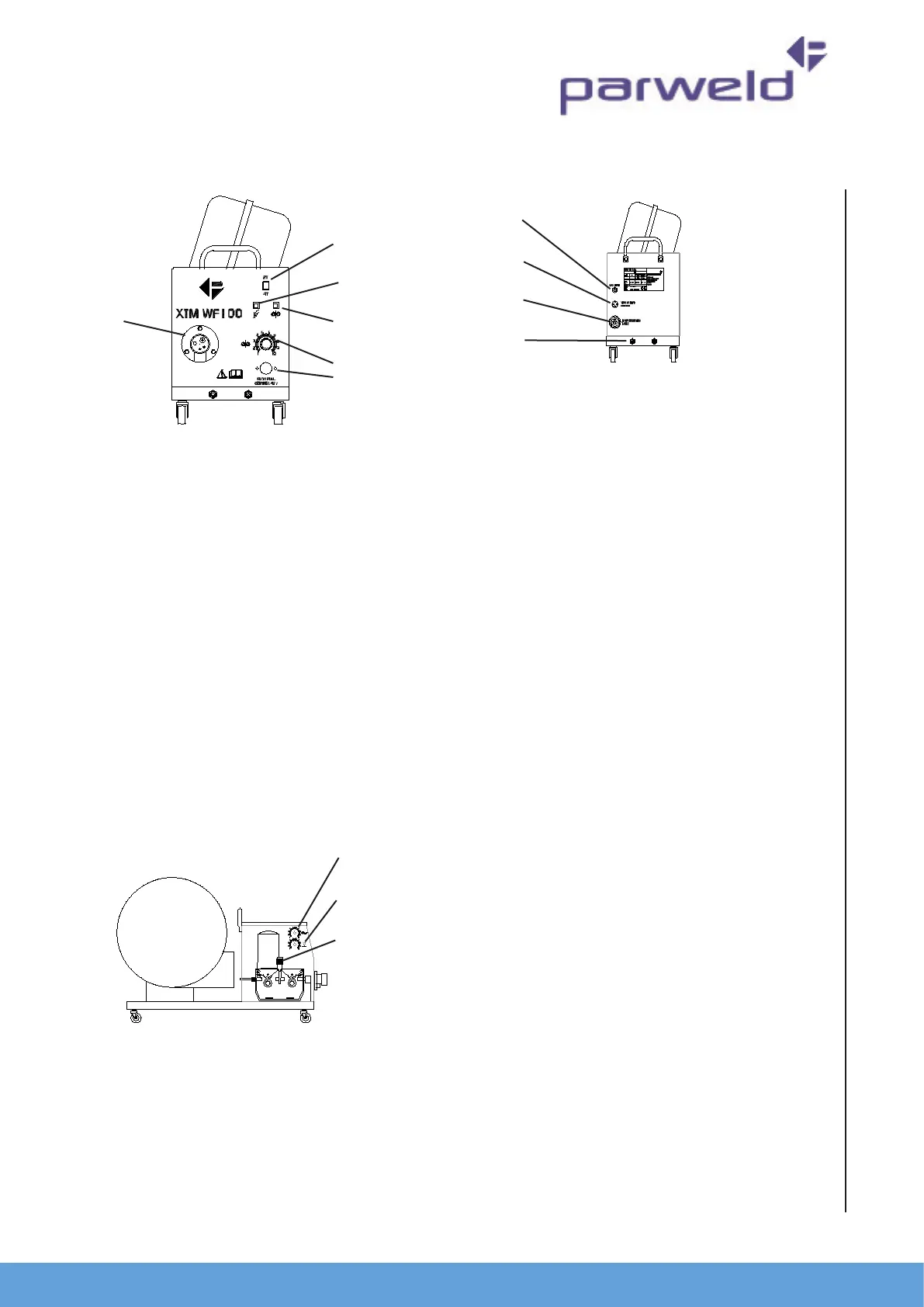

9. Work return lead connecon. High inductance

connecon, this should be used when in spray

transfer mode to give a more stable arc. (Only

ed to XTM403SW)

10. Filling spout for coolant Only use Parweld

Ultracool

11. Coolant level indicator, keep topped up between

min and max.

12. Control circuit protecon fuse

13. Mains input connecon Input connecon for the

pre-installed mains cable

14. Socket for the interconnecon cable to link to the

wire feeder.

15. Water IN/OUT snap connecons

16. Welding power connecon to connect to the inter

connect cable.Protecon fuse for the Auxiliary

output

17. 2T 4T, when in the 2T posion the torch trigger

will have a momentary operaon i.e. the welding

operaon will start when the rigger is depressed

and stop when it is released. In the 4T posion a

short press and release of the trigger will start the

welding operaon and a short press and release

with stop the operaon. The 4T mode is ideal for

long welds as it reduces operator fague.

18. Gas purge buon. Pressing this buon allow gas

to ow through the welding torch and so allow

checking of the gas ow before starng the

welding process.

19. Wire inching buon, allows the welding wire to be fed through the

torch without engergising the welding power.

20. Wire feed speed adjustment, controls the speed of wire feeding from

0.8 to 24 m/min. Increasing the wire feed speed also has the eect of

increasing the welding current

21. Locaon for control socket if machine is ed with Push Pull torch

22. Torch connector The Euro connector provided the external

connecon for the welding torch

23. So start adjustment which controls the acceleraon of the wire feed

motor when the arc starts to reduce spaer and give a cleaner arc

iniaon.

24. Burn back control aects the wire feed motor over run when the

trigger is released and can be adjusted to ensure that the wire does

not burn back onto the contact p at the end of the weld

25. Pressure adjuster Used to adjust the pressure allied by the feed

rollers on the welding wire.

26. Shielding gas input connecon 3/8 BSP male connecon for the

shielding gas input.

27. Interconnecon cable control socket input

28. Welding power connecon.

29. Water connecons for inter-connect cable

5.0 Installaon

Read enre installaon secon before starng installaon.

SAFETY PRECAUTIONS

• ELECTRIC SHOCK can kill.

• Only qualied personnel should perform this installaon.

17

18

19

20

21

22

23

24

25

26

27

28

29

Loading...

Loading...