c. The required flow is calculated based on the design

temperature difference from the return to the supply

of the boiler. For a PFC-460 boiler with a design

temperature difference of 20°F, the calculation is as

follows:

Output 438,000

Required Flow =

________

=

_________

= 43.8 GPM

Δ

T x 500 20 x 500

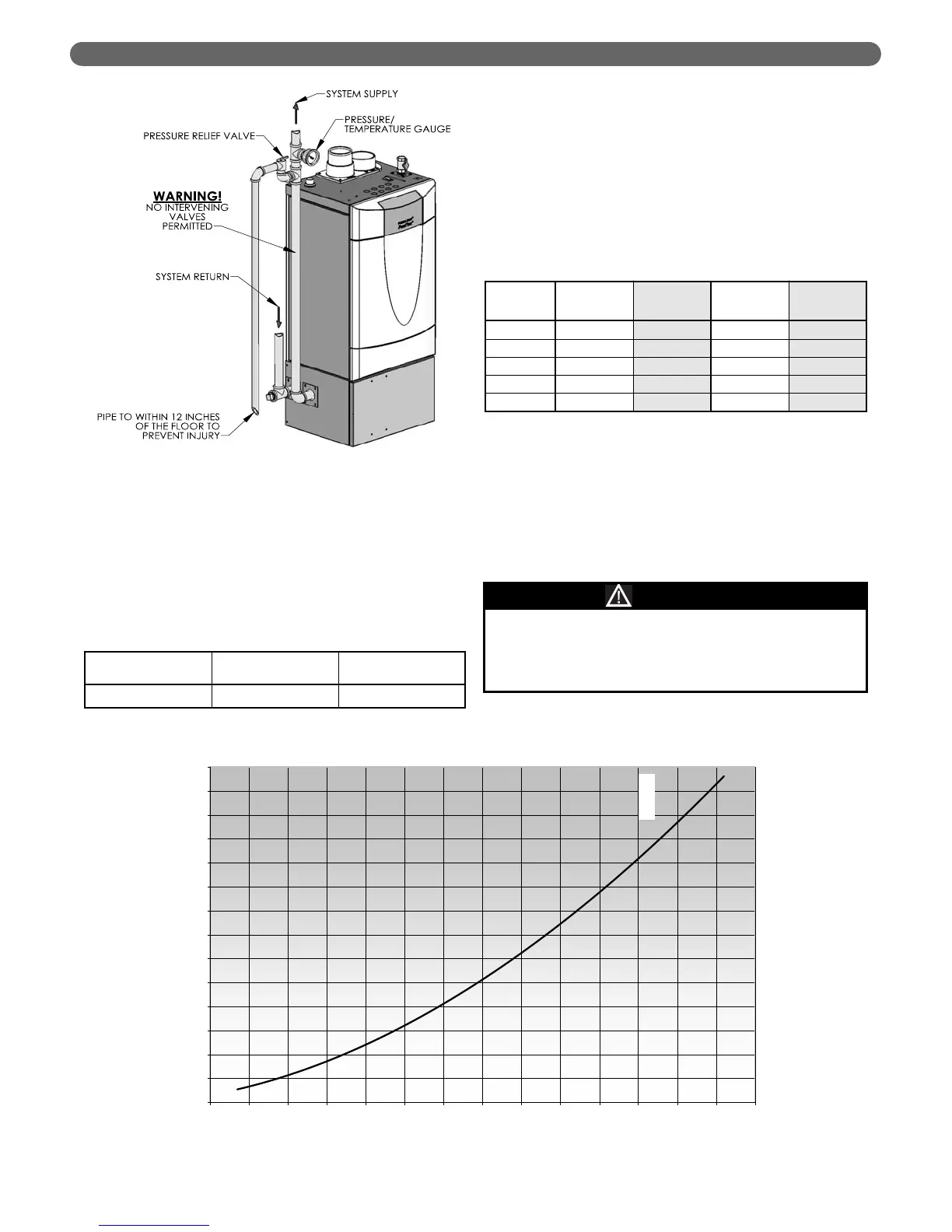

d. The boiler pressure drop for various flow rates can

be determined using Figure 4.3, the P

UREFIRE

®

Boiler Circulator Sizing Graph.

e. Table 4.4 provides the flow rate and pressure drop

information that corresponds to various system

temperature rise values (ΔT). The pressure drop

shown is for the boiler only. If there is significant

pressure drop in the system, this should be

included when specifying circulators.

f. Table 4.5 provides a list of recommended

circulators for boilers on a secondary loop of a

primary/secondary system which uses water as a

heating medium.

g. Special consideration must be given if a glycol

based anti-freeze solution is used as a heating

medium. Propylene glycol has a higher viscosity

than water, therefore the system pressure drop will

be higher.

18 18

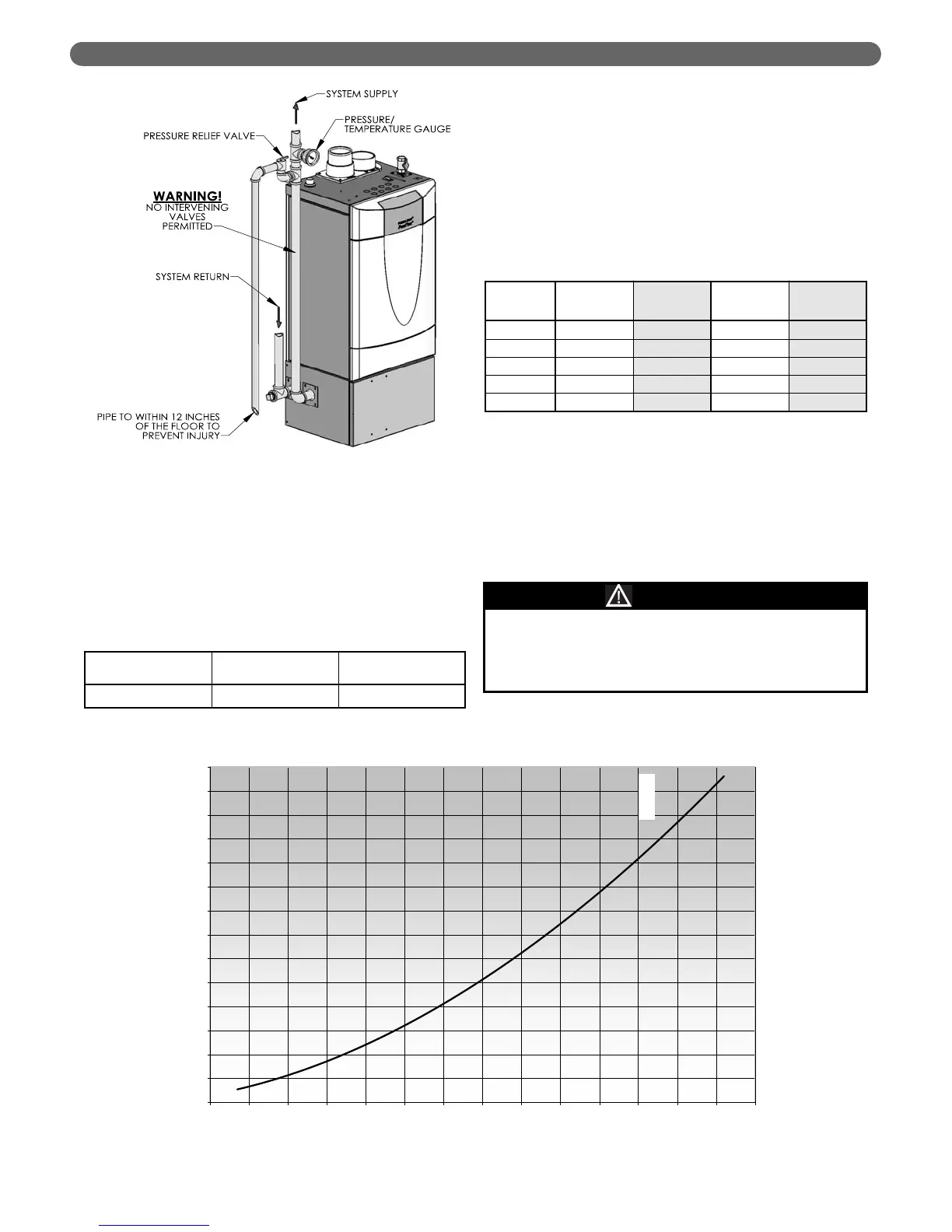

WATER PIPING AND CONTROLS

PUREFIRE

®

Model

Boiler Input

Btu/hr (kW)

Gross Output

Btu/hr (kW)

PFC-460 460,000 (134.8) 438,000 (128.8)

Table 4.3: Boiler Inputs and Outputs

Figure 4.3: PUREFIRE

®

Circulator Sizing Graph (General Pump – Primary/Secondary)

Pressure Drop (Ft. of Water)

PFC-460 Pressure Drop vs. Flow

Figure 4.2: Relief Valve Installation – PFC-460

Table 4.4: Flow Rate vs. Pressure Drop for Various

Boiler Temperature Rise Values

ΔT

(°F)

GPM FT LPM m

40 21.9 6.71 82.9 2.05

35 25.0 8.60 94.6 2.62

30 29.2 11.46 110.5 3.49

25 35.0 16.10 132.5 4.91

20 43.8 24.39 165.8 7.43

The circulator sizing given is for primary/secondary

installations only. The system circulators must be

sized based on the flow and pressure drop

requirements of the system.

NOTICE

Loading...

Loading...