27

A. GENERAL

1. All fuel piping to the PUREFIRE

®

boiler is to be in

accordance with local codes. In the absence of local

regulations refer to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

2. Size and install fuel piping to provide a supply of gas

sufficient to meet the maximum demand of all

appliances supplied by the piping.

3. P

UREFIRE

®

boilers are intended for operation with

Natural Gas or Propane with sulfur content of less than

105 ppm (150 mg/m

3

) peak with an annual average of

less than 20 ppm (30 mg/m

3

). Excessive sulfur content

in fuel input can result in black deposits resembling

coffee grounds in the combustion chamber of the boiler.

B. FUEL LINE SIZING

1. The required flow rate of gas fuel to the boiler can be

determined by the following.

The gas heating value can be supplied by the gas

supplier.

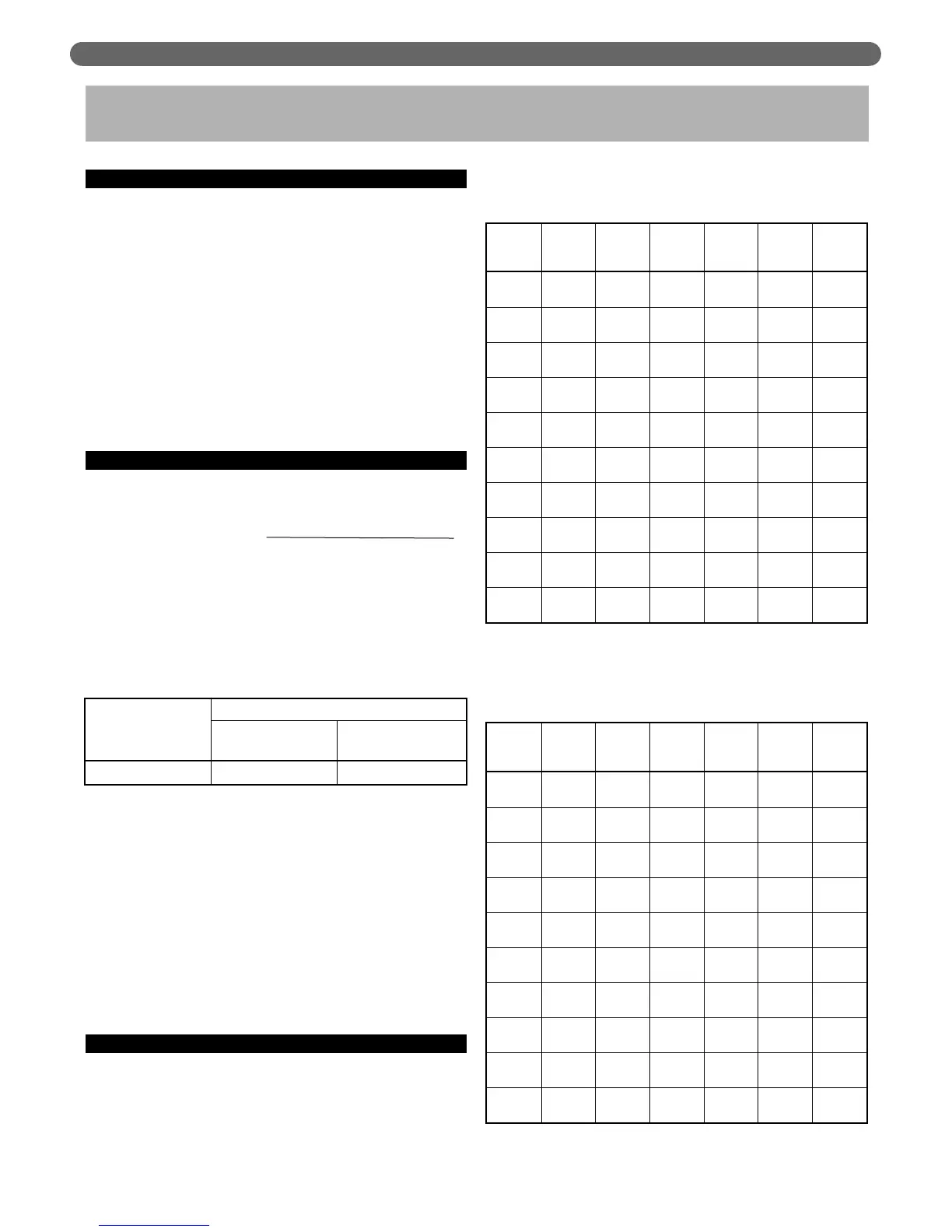

2. As an alternative, use Table 5.1 to determine the

required gas flow rate which uses typical heating values

for natural gas and liquefied petroleum (LP) gas.

3. Tables 5.2 and 5.3 shows the maximum flow capacity

of several pipe sizes based on 0.3" of pressure drop.

a. The values shown are based on a gas specific

gravity of 0.60 (Typical for natural gas).

b. Multiply the capacities listed by the correction

factors listed for gas with a specific gravity other

than 0.60 to obtain the corrected capacity.

4. Size and install the fuel gas supply piping for no more

than 0.5 inches of water pressure drop between the

gas regulator and the boiler.

C. GAS SUPPLY PIPING - INSTALLATION

1. Do not install any piping directly in front of the boiler

or along either side. Always provide access to the

front cover and side panel openings.

FUEL PIPING

5. FUEL PIPING

PUREFIRE

®

Model

Required Input Rate*

Natural Gas

ft

3

/hr (m

3

/hr)

LP Gas

ft

3

/hr (m

3

/hr)

PFC-460 460 (13.0) 184 (5.2)

Table 5.1: Required Fuel Input

Pipe

Length

ft (m)

1" Pipe

1-1/4"

Pipe

1-1/2"

Pipe

2" Pipe

2-1/2"

Pipe

3" Pipe

10

(3.0)

520

(14.7)

1,050

(30)

1,600

(45)

3,050

(86)

4,800

(136)

8,500

(241)

20

(6.1)

350

(9.9)

730

(21)

1,100

(31)

2,100

(59)

3,300

(93)

5,900

(167)

30

(9.1)

285

(8.1)

590

(17)

890

(25)

1,650

(47)

2,700

(76)

4,700

(133)

40

(12.2)

245

(6.9)

500

(14)

760

(22)

1,450

(41)

2,300

(65)

4,100

(116)

50

(15.2)

215

(6.1)

440

(12)

670

(19)

1,270

(36)

2,000

(57)

3,600

(102)

60

(18.3)

195

(5.5)

400

(11)

610

(17)

1,150

(33)

1,850

(52)

3,250

(92)

70

(21.3)

180

(5.1)

370

(10)

560

(16)

1,050

(30)

1,700

(48)

3,000

(85)

80

(24.4)

170

(4.8)

350

(10)

530

(15)

930

(26)

1,500

(42)

2,600

(74)

90

(27.4)

160

(4.5)

320

(9)

490

(14)

870

(25)

1,400

(40)

2,500

(71)

100

(30.5)

150

(4.2)

305

(9)

460

(13)

710

(20)

1,130

(32)

2,000

(57)

Table 5.2: Pipe Capacity - Natural Gas:

Maximum Capacity of pipe in cubic feet per hour (cubic meters

per hour) with a pressure drop of 0.3" of water (75 Pa).

Boiler Input Rate

Gas Heating Value

Input Rate

(

ft

³

/

hr

)

=

(

Btu

/

hr

)

(

Btu

/

ft

³

)

* Natural gas input rate is based on 1,000 Btu/ft

3

, LP input rate

is based on 2,500 Btu/ft

3

.

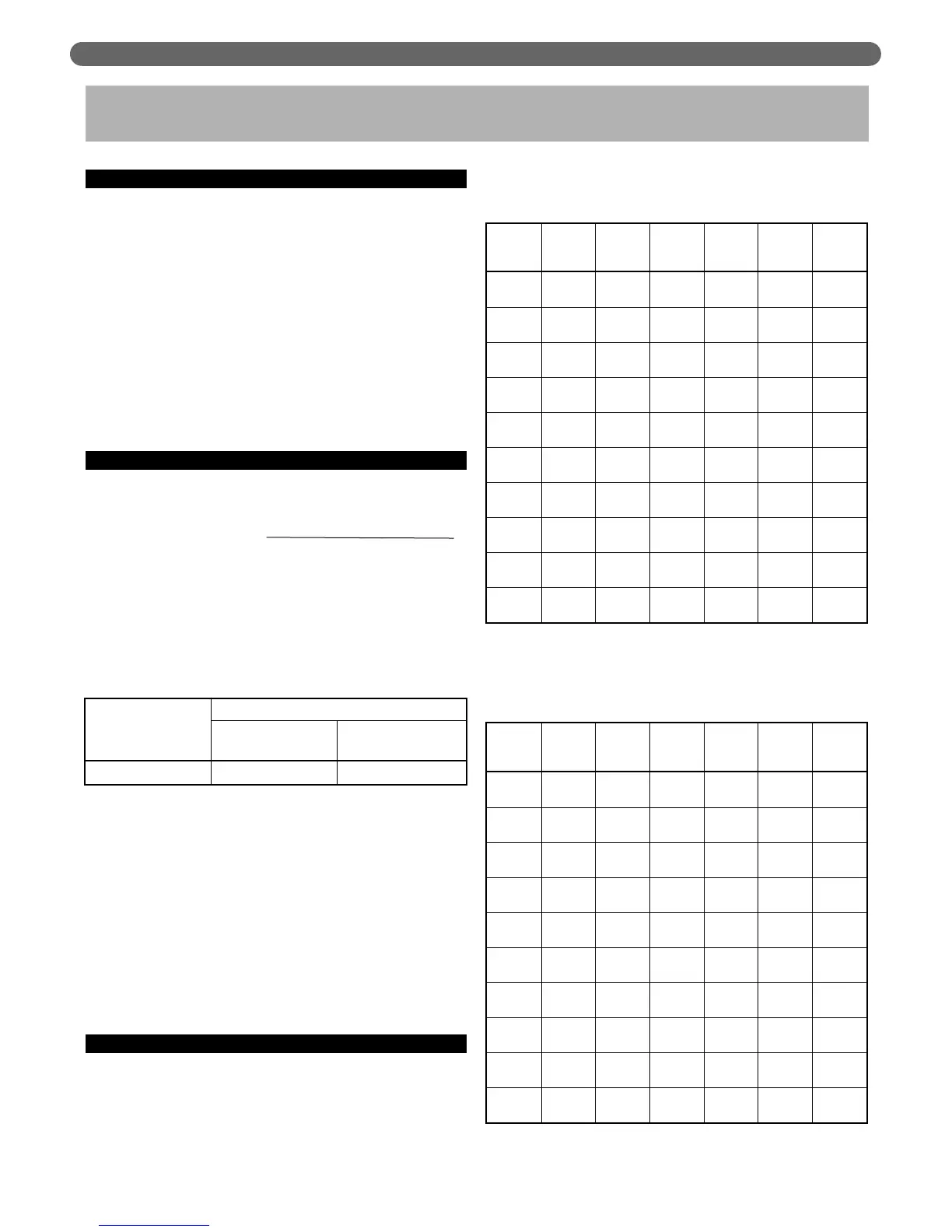

Pipe

Length

ft (m)

1" Pipe

1-1/4"

Pipe

1-1/2"

Pipe

2" Pipe

2-1/2"

Pipe

3" Pipe

10

(3.0)

328

(9.3)

662

(18.7)

1,008

(28.5)

1,922

(54.4)

3,024

(85.6)

5,355

(151.6)

20

(6.1)

221

(6.3)

460

(13.0)

693

(19.6)

1,323

(37.5)

2,079

(58.9)

3,717

(105.3)

30

(9.1)

180

(5.1)

372

(10.5)

561

(15.9)

1,040

(29.4)

1,701

(48.2)

2,961

(83.8)

40

(12.2)

155

(4.4)

315

(8.9)

479

(13.6)

914

(25.9)

1,449

(41.0)

2,583

(73.1)

50

(15.2)

136

(3.9)

277

(7.8)

422

(12.0)

800

(22.7)

1,260

(35.7)

2,268

(64.2)

60

(18.3)

123

(3.5)

252

(7.1)

384

(10.9)

725

(20.5)

1,166

(33.0)

2,048

(58.0)

70

(21.3)

114

(3.2)

233

(6.6)

353

(10.0)

662

(18.7)

1,071

(30.3)

1,890

(53.5)

80

(24.4)

107

(3.0)

221

(6.2)

334

(9.5)

586

(16.6)

945

(26.0)

1,638

(46.4)

90

(27.4)

101

(2.8)

202

(5.7)

309

(8.7)

548

(15.5)

882

(25.0)

1,575

(44.6)

100

(30.5)

95

(2.7)

192

(5.4)

290

(8.2)

447

(12.7)

712

(20.2)

1,260

(35.7)

Table 5.3: Pipe Capacity - LP Gas (1.50 Specific

Gravity)

Maximum Capacity of pipe in cubic feet per hour (cubic meters

per hour) with a pressure drop of 0.3" of water (75 Pa).

Loading...

Loading...