52

calculated based on the Calculated Setpoint

Max offset up. Similarly, if the system target is

above its target a calculated negative offset based

on the Calculated Setpoint Max offset down

is applied. The maximum increased setpoint

temperature is 195°F (91°C).

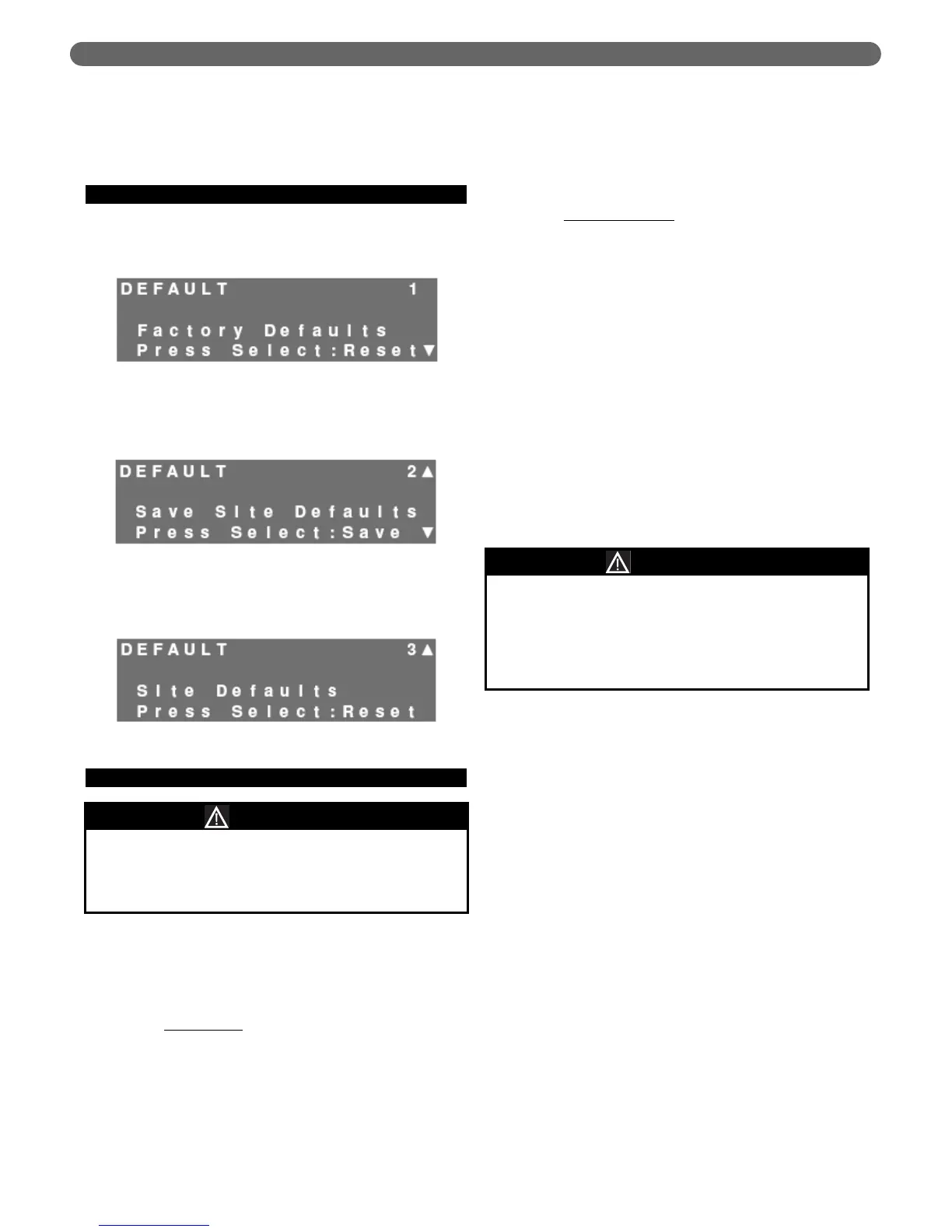

E. DEFAULTS

1. Factory Defaults – Restore: By pressing the

“Select” key while in the “Factory Defaults” screen.

All factory settings will be restored on the control.

2. Site Defaults – Save: To save the current settings as

“Site Defaults,” press the “Select” key while in the

following menu.

3. Site Defaults – Reset: To restore the “Site Defaults,”

press the “Select” key while in the following menu.

F. MULTIPLE BOILERS

1. PUREFIRE

®

boiler controls can operate together to

control up to 16 boilers for one central heat or domestic

hot water demand. Only the addition of a system

sensor (54156) is required to provide this operation.

2. Overview:

a. Master Boiler

: In a multiple boiler system, a boiler

designated as the “Master” boiler controls the

function of the boiler system.

• Attached to a system sensor which monitors

the system water temperature.

• Can also be connected to an outdoor sensor

(54112), included with each boiler, as well as

an optional DHW sensor (54157) or a

standard DHW thermostat.

• Determines which boiler operates first (lead)

and when to bring on additional boilers.

• Determines the setpoint temperature of

individual boilers.

• Shuts down all boilers in the system if the

LWCO contacts are opened.

b. Dependent Boilers

: The “dependent” boilers

operate at the setpoint temperature that the

Master boiler specifies.

• Maintain all of their own safety parameters

such as safety limit, vent temperature limit,

and freeze protection.

• Control their own general circulator that is

energized whenever there is a call for either

Central Heat or Domestic Hot Water.

• Shuts down the individual boiler if the

dependent boiler LWCO contacts are opened.

3. System Piping & Wiring:

a. Multiple boilers with multiple zones with zone valves.

• Figure 8.49 shows a typical system which uses a

CH circulator, a DHW circulator and zone valves

to distribute the heating load to the building.

• A three zone valve control panel (not included)

controls circulation to individual zones.

• A call from any of the heating zones initiates a

contact closure from the zone relay across the

CH thermostat connections (terminals #1 &2)

on the master boiler. This initiates ignition of

the “lead” boiler and its general pump. In

addition, the CH circulator is energized.

• A call for domestic hot water can either be

initiated internally by the control when it sees

a drop in indirect tank temperature or by a

tank thermostat. In either case, the lead boiler

is ignited and its general pump operates. The

DHW circulator is also energized.

b. Multiple boilers with multiple zones with zone

circulators.

• Figure 8.50 shows a typical system which uses

a circulator zone control panel to control the

central heating zones.

• The DHW circulator can be operated by the

priority zone or can be connected directly to

the boiler (as shown). In either case, the

priority zone cannot be used for heating.

• Again, a call for heat from any of the heating

zones causes the master boiler to initiate

operation of the lead boiler and its general

circulator. The CH circulators are controlled by

the zone control relay panel.

Figure 8.46: Restore Factory Defaults Screen

Figure 8.47: Save Site Defaults Screen

Figure 8.48: Restore Site Defaults Screen

Before selecting cascade operation, connect the

System sensor to terminals #7 & #8. Failure to do

this will result in a blinking screen warning as

covered in Section 10.D.

NOTICE

The central heating (CH) circulator and the domestic

hot water (DHW) circulator must be sized in

accordance with good Engineering practices based

on the required flow and pressure drop of the

system. Failure to do so may result in system

performance problems.

NOTICE

BOILER CONTROL: OPERATION

Loading...

Loading...