66

F. DELAYED IGNITION (HARD LIGHT-OFF)

There are several factors that may cause a delayed ignition

in the PureFire boiler due to a pressure pulse at light-off.

G. BOILER FAILS TO RESPOND TO A

CH CALL

If the display screen shows “STANDBY” and does not

respond when a thermostat call has been initiated, use the

following procedure to check operation.

1. Enter the “Installer Menu” by pressing the “Menu/Return”

key and the “Select” key simultaneously for 5 seconds.

2. Using the “

M”key move the cursor to “SYSTEM

TEST” and press “Select”.

3. Use the “M”key again to move the cursor to “Low

Power”.

4. Press the “Menu/Return” key twice to return to the status

screen.

5. If the boiler operates, return to “SYSTEM TEST” and

select “OFF”. If not, contact technical support.

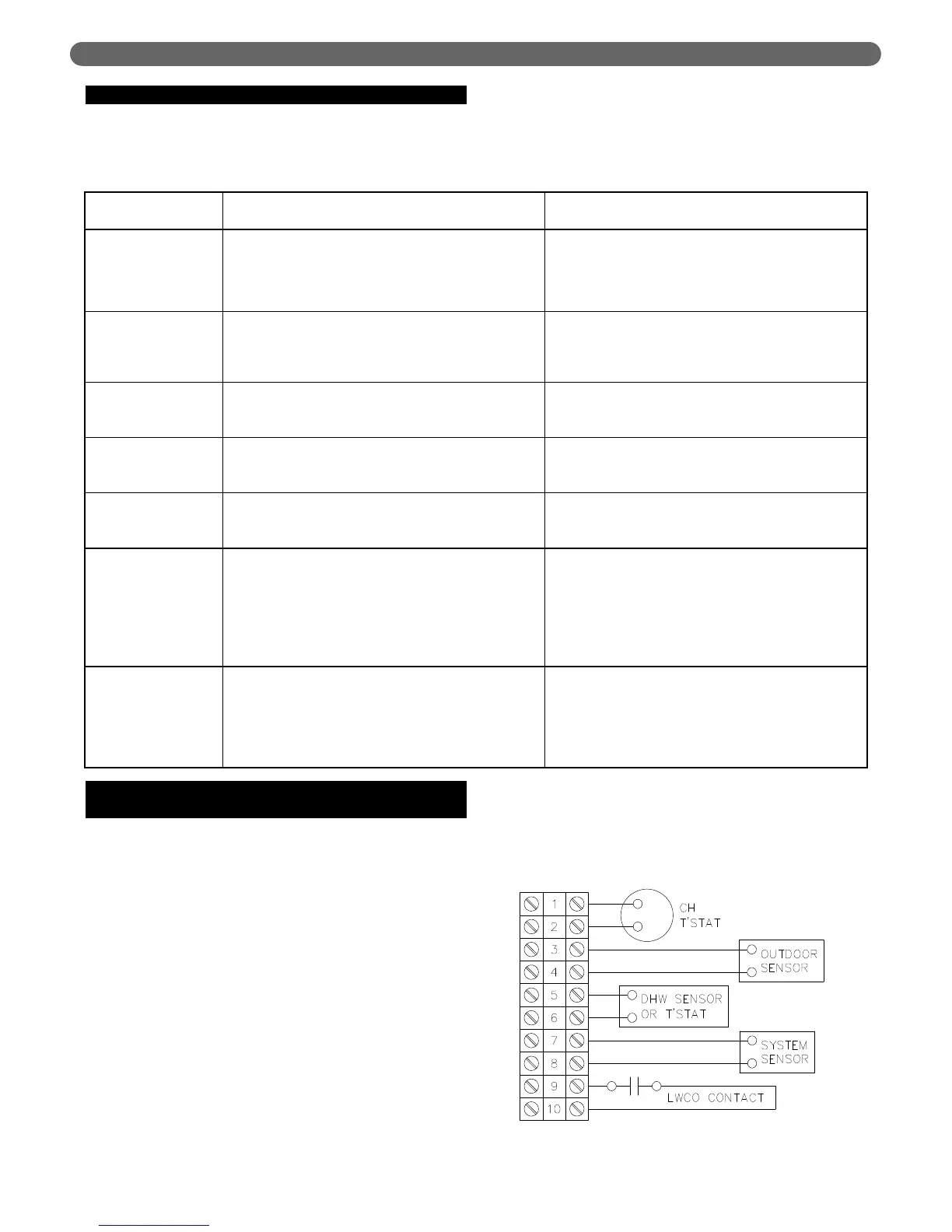

6. Next, remove any wires from terminals #1 & #2 (CH

Thermostat). See the illustration below.

7. Place a jumper in terminals #1 & #2, shown in Figure

10.2 below, to simulate a heating call.

8. If the boiler operates, there may be voltage feedback to

the thermostat terminals from the source. Check for stray

voltage or isolate the contacts.

Table 10.4: Hard Light-Off Conditions:

Condition

Condition Description Corrective Action

LOW GAS PRESSURE

If the gas inlet pressure at the inlet port on the gas valve is

below 3.5" of water for Natural Gas and 8” of water for

LP at 100% of modulation, a hard light-off may occur.

This may be due to slow introduction of the gas/air mix-

ture at light-off.

Be sure that the incoming gas pressure does not drop

below 3.5" of water for Natural Gas and 8” of water for

LP at any point in its operation. Be sure to check while

other appliances are in operation.

HIGH GAS PRESSURE

If the gas inlet pressure at the inlet port on the gas valve is

above 13.5" of water when the boiler is off, a delayed

ignition may occur. This is because the gas pressure may

inhibit the smooth opening of the gas valve at light-off.

Be sure that the incoming gas pressure is not above 13.5"

while the boiler is off or at any time during its operation.

INCORRECT

AIR/FUEL RATIO

Using a suitable combustion analyzer, check the products

of combustion to assure correct combustion air/fuel ratio

as described in Section 9.D.7 of these instructions.

If the vent CO

2

or CO is out of range in accordance with

table 5.4 in these instructions, please contact your PB

Heat representative.

SPARK GAP IS

TOO LARGE

If the spark gap between the ignition electrode and

ground rod is too large, a delayed ignition may occur.

This may be due to decreased spark energy of the larger

If the boiler is natural gas-fired, the spark gap should be

between 1/8" and 3/16". If the fuel is LP gas, the spark

gap should be between 3/16" and 1/4".

SPARK GAP IS

TOO SMALL

If the spark gap between the ignition electrode and

ground rod is too small, a delayed ignition may occur.

This may be due to a narrow ignition window from the

If the boiler is natural gas-fired, the spark gap should be

between 1/8" and 3/16". If the fuel is LP gas, the spark

gap should be between 3/16" and 1/4".

SPARK PLACEMENT

If the placement of the spark is the wrong distance from

the burner a delayed ignition may occur. The distance of

the spark from the burner surface should be approximately

3/8". If the spark gap is farther away from the burner, a

significant amount of combustible mixture may be intro-

duced into the combustion chamber before ignition. This

may result in a delayed ignition.

If the spark gap is more than 3/8" from the burner, replace

the ignitor and assure that the spark is 3/8" or less.

WEAK SPARK

A weak spark at the gap between the ignition electrode

and ground rod on the ignitor may be attributed to sever-

al problems.

1. Deterioration of the insulated spark wire

2. Dirt on the insulated portion of the spark electrode that

may provide a path for spark energy to ground

1. Check the spark wire for wear or damage. Replace if

necessary.

2. Check the porcelain insulation on the spark electrode

for evidence of dirt. Clean the insulator if dirt is evi-

dent.

TROUBLESHOOTING

Figure 10.2: CH Thermostat Terminals

Loading...

Loading...