2

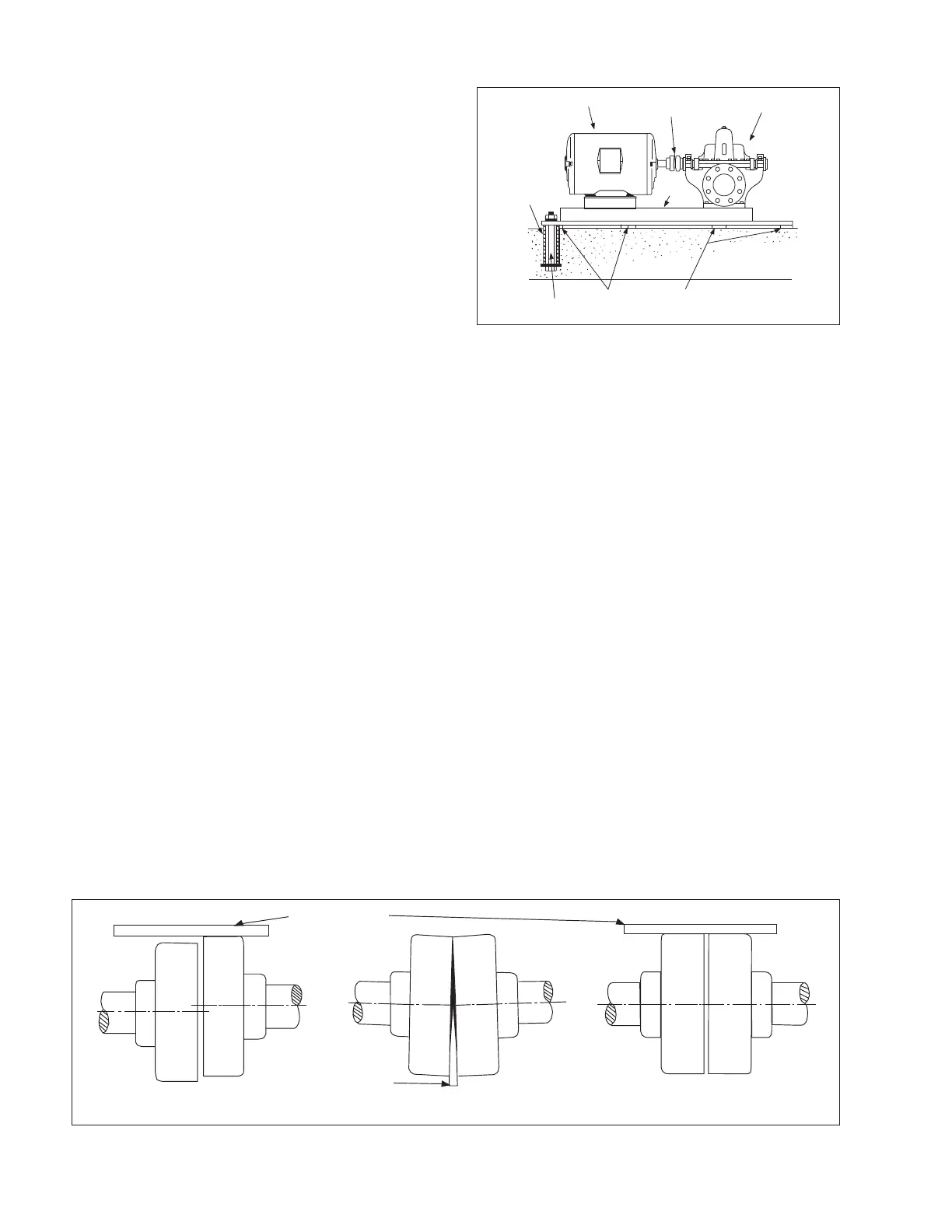

FOUNDATION. The foundation for your pump must be

sufficiently rigid to absorb any vibration and stress encountered

during pump operation. A raised foundation of concrete is

preferable for most floor mounted pumps. The raised foundation

assures a satisfactory base, protects against flooding, simplifies

moisture drainage, and facilitates keeping the area clean.

Your pump should be firmly bolted to the foundation, whether it

is a raised concrete base, steelwork wall, or structural member.

The mounting bolts or lag screws should be accurately located

per the applicable Aurora

®

dimension sheet. Refer to Fig. 1.

LEVELING THE PUMP. Leveling the pump will require

enough shims to support the baseplate near the foundation bolts

and at any points of the baseplate carrying a substantial weight

load. The shims should be large enough to allow a gap of 3/4"

to 1-1/2" between the baseplate and foundation for grouting.

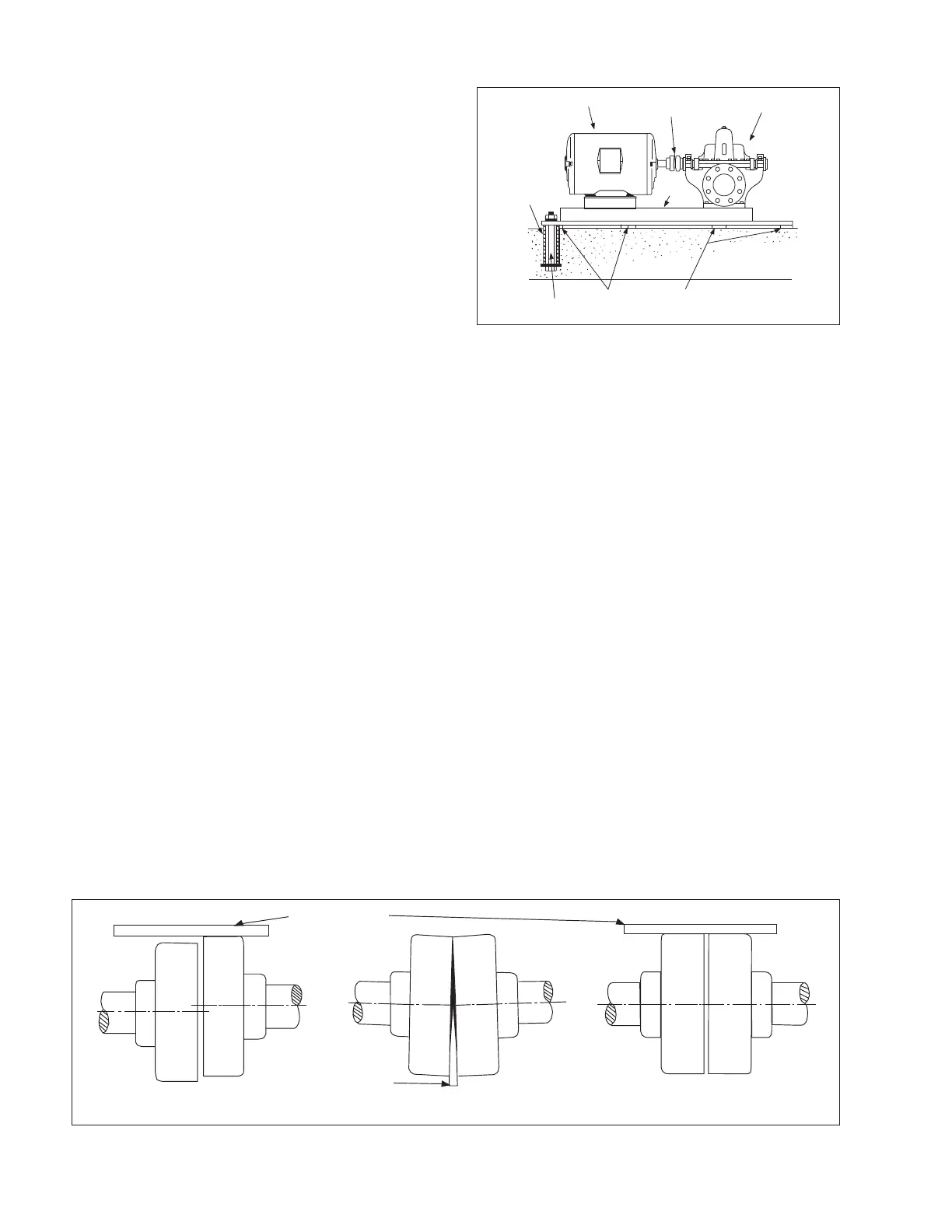

INITIAL ALIGNMENT OF THE FLEXIBLE COUPLING.

The pump and driver were accurately aligned at the factory.

However, it is impossible to maintain this alignment during

shipping and handling. Therefore it will be necessary for you

to realign the pump and driver. Flexible couplings are not

universal joints. They should not be used to compensate for

misalignment of the pump and motor shafts. Their function is to

transmit power from the driver to the pump while compensating

for thermal expansion and shaft end movement. The coupling

faces should be far enough apart so that they do not make

contact when the motor shaft is forced to the limit of the bearing

clearance toward the pump shaft.

In order to properly align the coupling, you will need a taper

gauge or set of feeler gauges and a straight edge.

There are two types of misalignment encountered with flexible

couplings: angular misalignment, in which the shafts are not

parallel, and parallel misalignment where the shafts are parallel

but not on the same axis.

To check angular alignment, insert a feeler gauge or taper gauge

at any four places 90° apart around the coupling halves. Insert

shims under the driver feet until the same reading is obtained

at all four checkpoints. The pump and driver will then be in

angular alignment.

To check parallel alignment, a straight edge should be held

against the edges of the coupling halves at any four places 90°

apart around the coupling. The straight edge should be parallel

to the pump and driver shafts at all times. Insert shims until

the straight edge lies flat against both coupling halves at all

four checkpoints. The pump and driver will then be in proper

parallel alignment. Refer to Fig. 2.

SUCTION PIPING. The suction piping should be short, but no

less than ten pipe diameters in length, and direct with as few

elbows and fittings as possible to keep head loss, from friction,

at a minimum. However, the suction pipe should provide a

minimum uninterrupted length, equal to ten pipe diameters, to

the pump suction flange. A horizontal suction line should have a

gradual rise to the pump and pass under any interfering piping.

The suction pipe diameter should be at least the same diameter

as the suction nozzle on the pump, and preferably larger. Use

of a smaller diameter pipe will result in loss of head due to

friction. All joints must be tight to maintain prime on the pump.

REDUCERS. Eccentric reducers should be installed directly at

the suction nozzle, with the taper at the bottom to prevent air

pockets from forming. Straight taper reducers should never be

used in a horizontal suction line because of the air pocket that is

formed at the leg of the reducer and the pipe. Refer to Fig. 3.

ELBOWS. Long radius elbows should be used in place of

standard elbows wherever possible because of their superior

flow characteristics. For instance, head loss in a standard four

inch elbow is equivalent to the head loss in a piece of pipe

11 feet long, while the head loss in a long radius elbow is

approximately half as much. Elbows should not be used at the

suction nozzle, but if it is unavoidable, they should be installed

in a vertical position. Elbows installed in any position at the

suction nozzle have a tendency to distribute the liquid unevenly

in the impeller chamber, causing a reduction in capacity, and

creating an undesirable thrust condition. Refer to Fig. 4.

SHIMS

SHIMS

FOUNDATION BOLT

GROUTING CLEARANCE

PIPE

DRIVER

FLEXIBLE COUPLING

PUMP

BASEPLATE

CONCRETE

FOUNDATION

Figure 1. Foundation for frame mounted pumps.

STRAIGHT EDGE

PARALLEL MISALIGNMENT

ANGULAR MISALIGNMENT

WEDGE OR

THICKNESS GAUGE

PERFECT ALIGNMENT

Figure 2. Flexible coupling alignment.

MODELS 411-412-413

Loading...

Loading...