9

20. On pump Model 412, attach flexible shafting. Ideal

joint operating angle is 1º to 5º on pump Model

411. If lower casing was removed from the base, see

section on Installation for proper methods of realigning

pump to motor and piping.

21. Replace any flushing, cooling, bypass or drain lines that

were removed from the pump. Connect electricity back to

the motor.

STARTING PUMP AFTER REASSEMBLY

Do not start pump until all air and vapor have been bled, making

sure that there is liquid in pump to provide necessary lubrication.

NOTE

Do not overtighten standard packing assembly before

returning unit to operation. Jog the pump to check for

proper rotation. Then allow pump to run for a short time,

gradually tightening nuts (18) until dripping has been

reduced to its normal level.

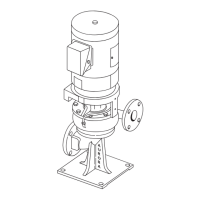

MODELS 411-412-413

Loading...

Loading...