6

NOTE

If the unit has a tandem shaft, protector (29) is not used.

16. Outboard bearing (38) is press fitted onto shaft (65). To

remove it, place a puller on bearing cartridge (36) and pull

cartridge, grease seal (37) and bearing from shaft. The

grease seal can be pressed from the bearing cartridge if it

needs replacing, then slide slinger (39), lantern ring (52) and

bushing (56) off shaft (65) single stage, (71) two stage.

Refer to Fig. 11.

17. Removal of inboard bearing is basically the same as for out-

board bearing. Remove capscrews (41) and slide slinger (40),

cartridge cap (42), grease seal (43) and gasket (44) off shaft.

18. Pull or press off bearing cartridge (45), grease seal (46) and

bearing (47). Remove slinger (48), lantern ring (52) and

bushing (56) from shaft.

19. If pump has right-hand rotation, unscrew and remove outboard

sleeve (57) first. Remove O-ring (62) single stage, (58) two

stage. If pump has left-hand rotation, unscrew and remove

inboard sleeve (64) single stage, (65) two stage first. Remove

O-ring (58) single stage, (66) two stage. Refer to Fig. 12.

20. Key (63) holds impeller (59) and either sleeve (64) if pump is

right-hand or sleeve (57) for a left-hand pump. These parts

can be removed by pulling impeller from shaft (65) and

removing key (63) from its position in keyway and sleeve.

Unscrew and remove remaining sleeve and gasket.

21. Disassemble wearing ring(s) (61) (optional) from impeller

(59) only if necessary. On power frames 5, 6B and 7, remove

setscrews (78). Apply a puller and gradually withdraw

wearing rings (61) from impeller (59). Wearing rings may

have to be cut or trimmed off the impeller. If a lathe is used to

trim rings off, use care not to clamp impeller too tight and

cause distortion. Also use care not to remove any metal

from impeller.

22. Remove locking and locating pins (66, 67 and 68) from

casing half (69) only if replacement is necessary.

23. Nameplate and its securing screws should be removed only if

replacement is necessary.

24. For pump Model 413 unscrew capscrews (75) to remove

motor and motor bracket (74) from casing half (69). The

motor can be separated from motor bracket by removing

capscrews (73).

DISASSEMBLY OF A PUMP WITH MECHANICAL SEALS

1. Perform disassembly procedure as previously given through

step 8.

2. Loosen and remove four nuts (18) and washers (19) thus

freeing swing bolts (22) to allow shaft and impeller assembly

to be lifted from casing half (69) with sling and hoist or crane

as described in paragraph 10.

Use extreme care in moving assembly. Mechanical seal,

seats and washers can be cracked by just sliding loose on

shaft. To prevent this, wrap seal securely in a shop cloth

or other protective covering.

3. With shaft and impeller assembly on a suitable bench,

cradle, or work stand, loosen and remove pipe plug (12)

from inboard cartridge cap (42). Remove grease zerk (10)

and capscrews (41) and slide the cartridge cap with grease

seal (43) off end of shaft (71). Remove gasket (44).

4. Pull or press bearing cartridge (45), grease seal (46) and

bearing (47) off shaft. Remove slinger (48).

5. One piece gland (49) used with mechanical seal assembly

can now be removed from shaft. O-ring (50) can be

removed from seal gland if desired.

Exercise great care in removing seal assembly (53) to

keep from marring or otherwise damaging precision

ground mating surfaces.

6. Scribe a mark on shaft sleeves for relocating seal collar on

reassembly. Loosen setscrews (55), securing seal collars

(54) to shaft sleeves and slide them off.

7. Proceed with further disassembly of outboard ball bearing

and seal assembly using same basic procedure.

8. After removal of mechanical seals, proceed with balance

of disassembly in the same manner as described for pack-

ing design.

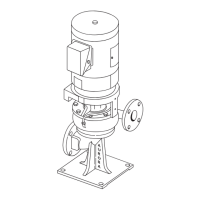

Figure 11. Outboard rotating element components removed,

illustrating disassembly.

Figure 12. Sleeve and O-ring removed.

CAUTION

CAUTION

MODELS 411-412-413

Loading...

Loading...