3

GROUTING THE INSTALLATION. Grouting the baseplate

prevents lateral movement of the baseplate and improves

the vibration absorbing characteristics of the foundation by

increasing its mass. A wooden dam should be constructed

around the baseplate to contain the grout while it is being

poured. The dam can be built tight against the baseplate or

slightly removed from it as desired.

The entire baseplate should be completely filled with a non-

shrinkable type grout. The grout should be puddled frequently

to remove any air bubbles from the grout.

DISCHARGE PIPING. Discharge piping should also be short

and direct as possible, with few elbows and fittings, to reduce

head loss from friction.

PIPE. The discharge pipe diameter should be the same as, or

larger than, the discharge nozzle diameter. The size of discharge

pipe to be used is dependent upon the application.

DISCHARGE VALVES. The discharge piping should include a

check valve and a gate valve. The check valve should be located

between the gate valve and the pump. If an increaser is used in

the discharge piping, the increaser should be installed between the

pump nozzle and the check valve. The check valve protects against

a reverse flow of the liquid if the driver fails. Refer to Fig. 5.

The gate valve is used in the priming operation, as a throttling

valve to control pump volume and to shut down the pump for

inspection and maintenance.

ELECTRICAL WIRING. Normally, your pump will be sup-

plied with an attached drive motor. The motor should be wired

in accordance with the wiring diagram found on the motor

nameplate. Be sure the voltage, frequency and phase of your

power supply corresponds with the nameplate data. It is

advisable to provide a separate switch and overload protection

for your pump motor to protect against power failure in some

other area. Conversely, if the pump motor develops electrical

problems, it will be isolated from other equipment.

PRESTARTING INSTRUCTION. The coupling halves should be

connected. Prior to connection, however, the drive motor should

be started to make sure the direction of rotation is the same as the

direction indicated by the arrow on the pump casing.

CORRECT

DISCHARGE

SUCTION

DISCHARGE

SUCTION

INCORRECT

AIR POCKET

STRAIGHT TAPER REDUCER

ECCENTRIC TAPER REDUCER

Figure 3. Installation of tapered reducers.

CORRECT

PATH OF

WATER

SUCTION

INCORRECT

LESS DESIRABLE

IF ELBOW IS NECESSARY, IT

SHOULD BE THE LONG RADIUS TYPE.

DISTANCE EQUAL

TWICE DIAMETER

OF INLET PIPE

Figure 4. Installation of elbows.

CHECK

VALVE

DISCHARGE PIPING

GATE

VALVE

Figure 5. Gate valve and check valve.

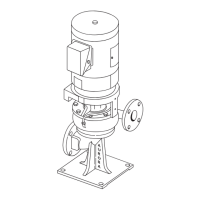

MODELS 411-412-413

Loading...

Loading...