4

Do not operate the pump without liquid. Pump seals or

packing depend on the liquid being pumped for lubrication.

Be sure the pump is primed and that no air exists in the suction

pipe and pump casing.

MAINTENANCE

Your Aurora

®

pump requires no maintenance other than

periodic inspection, lubrication and occasional cleaning. The

intent of inspection is to prevent breakdown, thus obtaining

optimum service life. The motor may require lubrication. The

motor manufacturer’s recommendation should be followed. For

all of the split case pump models, regreasable bearings are

standard. Oil lubrication is optional on the 431B pumps.

Regreasable bearings will require periodic lubrication and can

be accomplished by using the zerk or lubrication fittings in the

cartridge cap. Lubricate the bearings at regular intervals using a

grease of high quality. Aurora recommends Chevron SRI No. 2

grease with a polyurea thickener. However, most major brands

of Grade No. 2 ball bearing grease are satisfactory for pumps

oper at ing in both wet and dry locations. Mixing of different

brands of grease should be avoided due to possible chemical

reactions between the brands which could damage the bearings.

Accordingly, avoid grease of vegetable or animal base which

can develop acids, as well as grease containing rosin, graphite,

talc and other impurities. Under no circumstances should grease

be reused.

Overlubrication should be avoided as it may result in overheating

and possible bearing failure. Under normal application, adequate

lubrication is assured if the amount of grease is maintained at 1/3 to

1/2 the capacity of the bearing and adjacent space surrounding it.

In dry locations, each bearing will need lubrication at least

every 4,000 hours of running time or every 6 to 12 months,

whichever is more frequent. In wet locations the bearings

should be lubricated at least after every 2,000 hours of running

time or every 4 to 6 months, whichever is more frequent. A unit

is considered to be installed in a wet location if the pump and

motor are exposed to dripping water, to the weather, or to heavy

condensation such as is found in unheated and poorly ventilated

underground locations.

Oil lubricated bearings are optional on Model 431B pumps. A

fixed oil level is maintained with the bearing cartridge by an

oiler which allows visual indications of reserve oil.

At initial installation and before starting, a unit that has been

shut down for repairs or for any extended length of time, run

enough 10W-20 weight motor oil through the oiler to maintain

a constant oil level to ensure that the bearing will never be

without an oil supply. Oil will have to be added at intervals to

maintain a constant level in the oiler. This interval can be

determined only by experience.

Under working conditions, oil will break down and need to be

replaced at regular intervals. The length of these intervals will

depend on many factors. Under normal operation, in clean and

dry locations, the oil should be changed about once a year.

However, when the pump is exposed to dirt contamination, high

temperatures (200°F or above) or a wet location, the oil may

have to be changed every 2 to 3 months.

At times it may be necessary to clean the bearings due to accumulated

dirt or deteriorated lubricants. This can be accomplished by flushing the

bearing with a light oil heated 180 to 200ºF while rotating it on a spindle.

Wipe the bearing housing with a clean rag soaked in a cleaning solvent

and flush all surfaces.

Dry bearing thoroughly before relubricating. Compressed air

can be used to speed drying, but care should be taken not to let

bearings rotate while being dried.

Use normal fire caution procedures when using any

petroleum cleaner.

The motor that drives your Aurora pump may or may not require

lubrication. Consult the manufacturer’s recommendations for proper

maintenance instructions.

REPAIRS

The pump may be disassembled using the illustrations and text

provided. Although complete disassembly is covered, it will

seldom be necessary to completely disassemble your Aurora pump.

The illustrations accompanying the disassembly instructions

show a Model 411 pump at various stages of disassembly. The

illustrations are intended to aid in the correct identification of

the parts mentioned in the text.

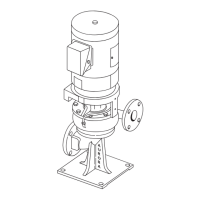

Refer to Figure 6 that illustrates the various pump models

described in this manual.

Inspect removed parts at disassembly to determine if they

can be reused. Cracked castings should never be reused. All

optional packing and gaskets should be replaced at reassembly

simply as a matter of economy. They are much less expensive to

replace routinely than to replace singly as the need arises. In

general it is economical to return to the manufacturer for repair

to the motor and motor controller.

DISASSEMBLY

Disassemble only what is needed to make repairs or accomplish

inspection. Proceed to disassemble the pump as follows:

CAUTION

Figure 6. The models shown above are single stage pumps in various

mounting configurations.

MODEL 412

MODEL 413

MODEL 411

CAUTION

MODELS 411-412-413

Loading...

Loading...