VERTICAL MULTISTAGE PUMPS

11

MAINTENANCE:

MOTOR REPLACEMENT. For Reference Numbers [shown as

(3) or (5)], refer to the Exploded View, Figure 14, for PVM2

and PVM4 series models, Figure 16 for PVMX2 and PVMX4

models, Figure 15 for PVM8 and PVM16 series models, and

Figure 17 for PVMX8 and PVMX16 series models.

1. Disconnect the power to the pump motor.

2. Close the nearest suction and discharge valves.

3. Remove the coupling guards (4) by prying them loose with a

screwdriver.

4. Remove the socket head screws (3) and the coupling halves

(2) from the shaft (16A). For additional reference, see Figure

12.

NOTICE: Socket head screws are metric. See Table VIII for

specific metric driver sizes.

5. Remove the shaft pin (5).

6. Remove the capscrews (12), flatwashers (10), and

lockwashers (11) that hold the motor (1) and the motor

bracket (7) together.

7. Pull the old motor up and off the motor bracket. NOTICE:

Note the location of the conduit box on the motor.

8. Thoroughly clean the surfaces of the mounting flanges on

the new motor and the pump end.

9. Install the new motor on the pump with the conduit box in

the desired position.

10. Lubricate the capscrews (12) with oil.

11. Reinstall the lockwashers, flatwashers, and capscrews

that hold the motor and the motor bracket together, then

tighten evenly and diagonally. See Table VIII for torque

specifications.

12. Reinstall the shaft pin (5) in the shaft.

13. Reinstall the coupling halves (2) on the pump and motor

shaft. Make sure to engage the shaft pin (5).

NOTICE: Be sure coupling surfaces are thoroughly clean

prior to assembly.

14. Snug up the socket head screws (3) until the coupling begins

to bind and then loosen 1/2 turn.

15. Draw up the capscrews evenly so the gap between the

coupling halves is equal on both sides (see Figure 10A).

16. Insert a screwdriver under the coupling (see Figure 10B).

17. Raise the pump shaft to its highest point.

18. Lower the shaft halfway back down the distance you just

raised it and retighten the capscrews. See Figure 10.

NOTICE: Torque settings are critical to prevent coupling

movement. Refer to Table VIII for torque specifications.

19. Rotate the shaft to make sure that there is no interference.

If rubbing is noted, repeat steps 16, 17, and 18 above and

readjust pump shaft height.

20. Reinstall the coupling guards by snapping them into place.

NOTICE: The guards should be in place before the unit is

run.

21. Open the suction and discharge valves. Turn the power back

on.

REPLACING PUMP STACK. For Reference Numbers [shown

as (3) or (5)], refer to the Exploded View, Figure 14 for the

PVM2 and PVM4 series models and Figure 15 for PVM8 and

PVM16 series models.

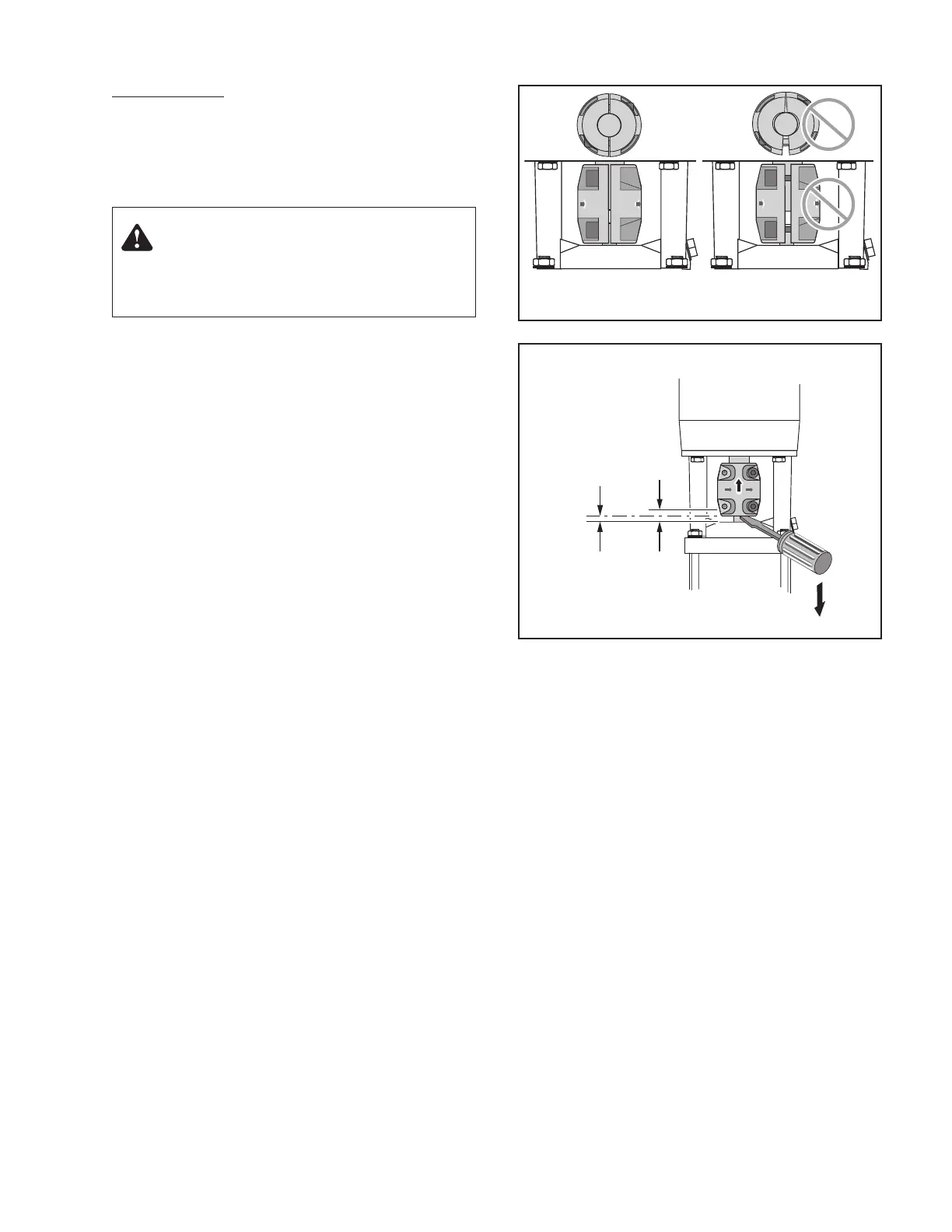

Figure 10A. Make sure that the coupling halves are

evenly tightened.

Warning: Hazardous Voltage

Disconnect all power to the pump before servicing or working

on pump. Make sure that power is locked out and that pump

cannot be accidentally started.

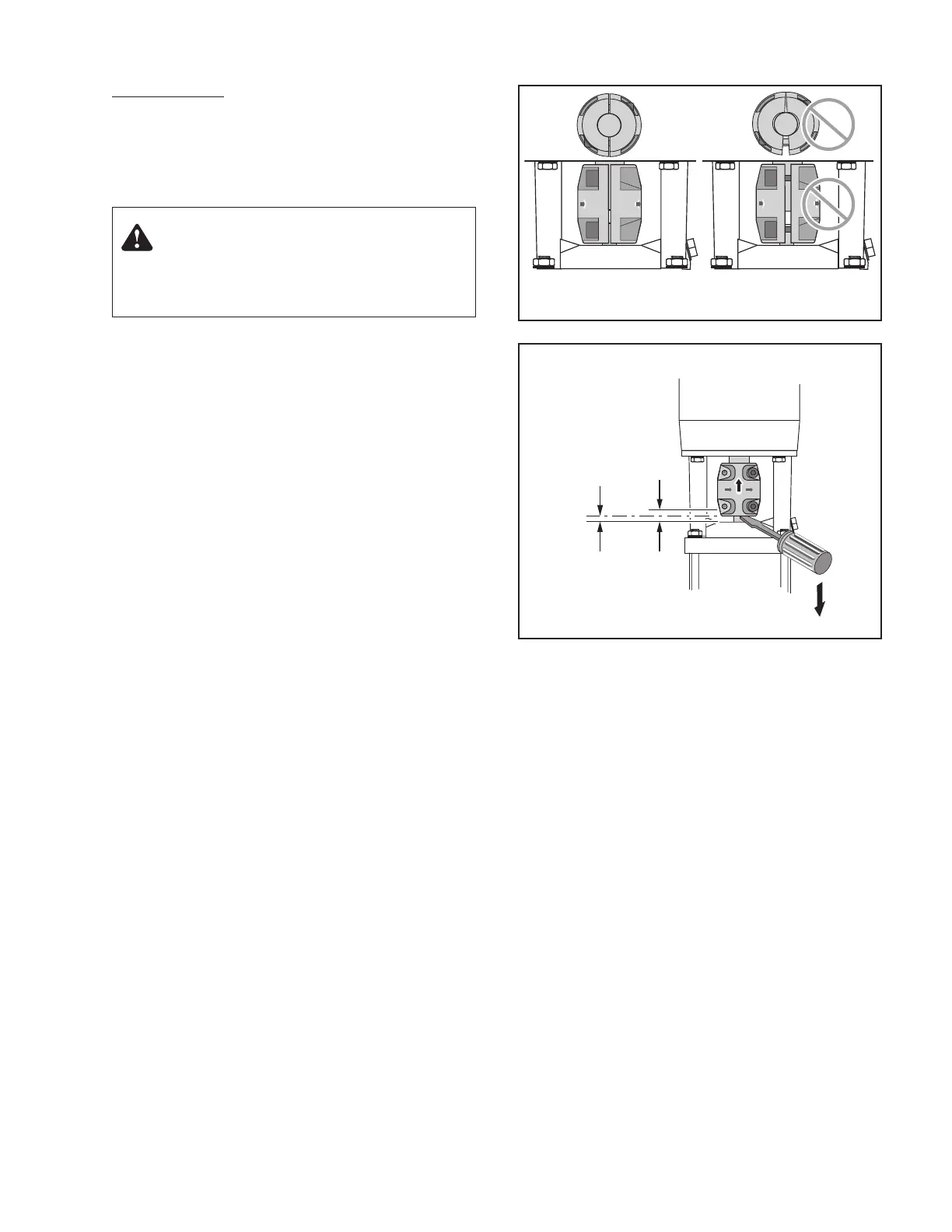

Motor

Pump

Raise Coupling

as far as it will go;

then tighten at

one-half the

height of total

axial play.

Axial

Play

Coupling

Setting

Figure 10B. Vertically (axial) centering the coupling.

Loading...

Loading...