P/N 475114 Rev. F 8/2020 MASTERTEMP 125 Pool and Spa Heater Installation and User’s Guide

| 3

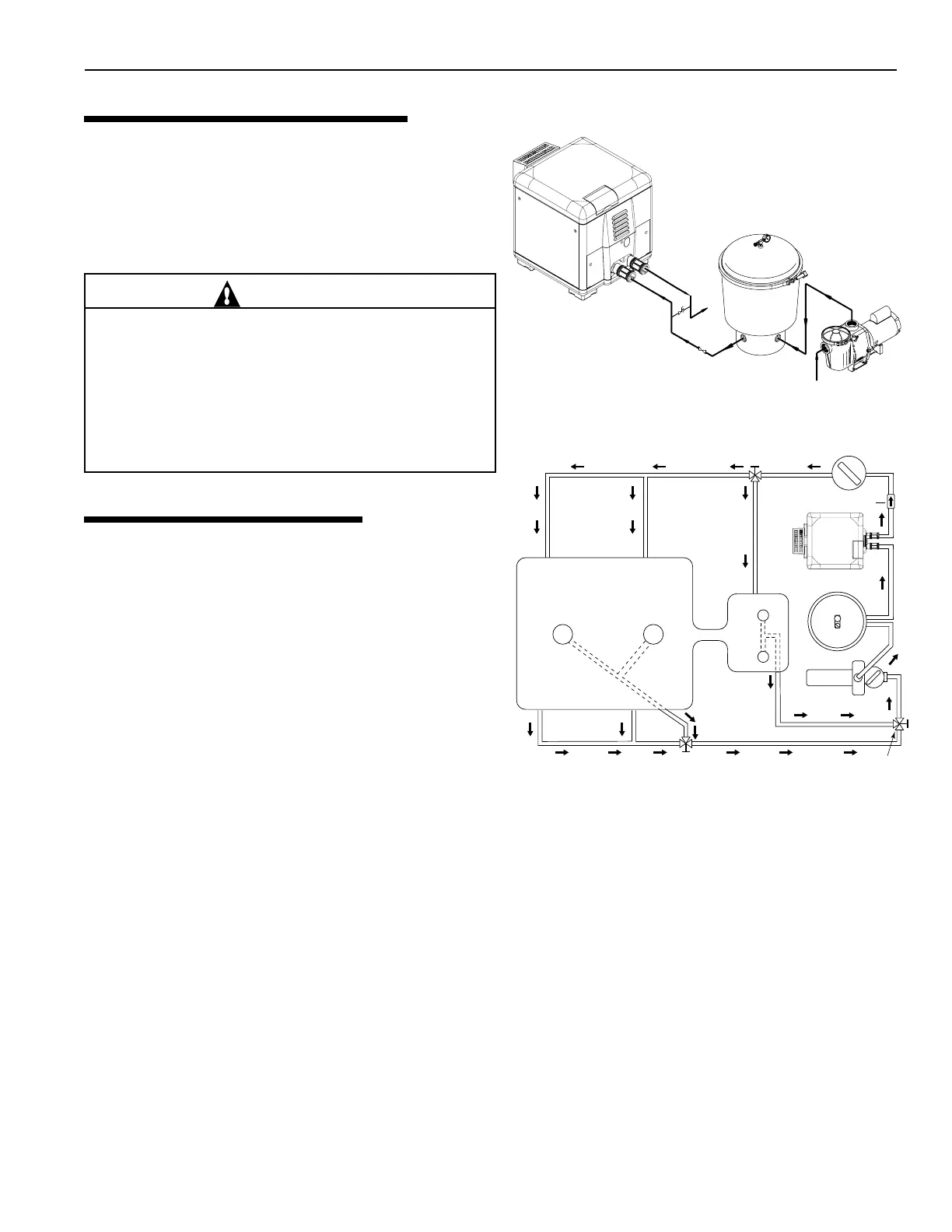

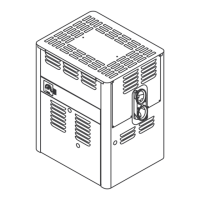

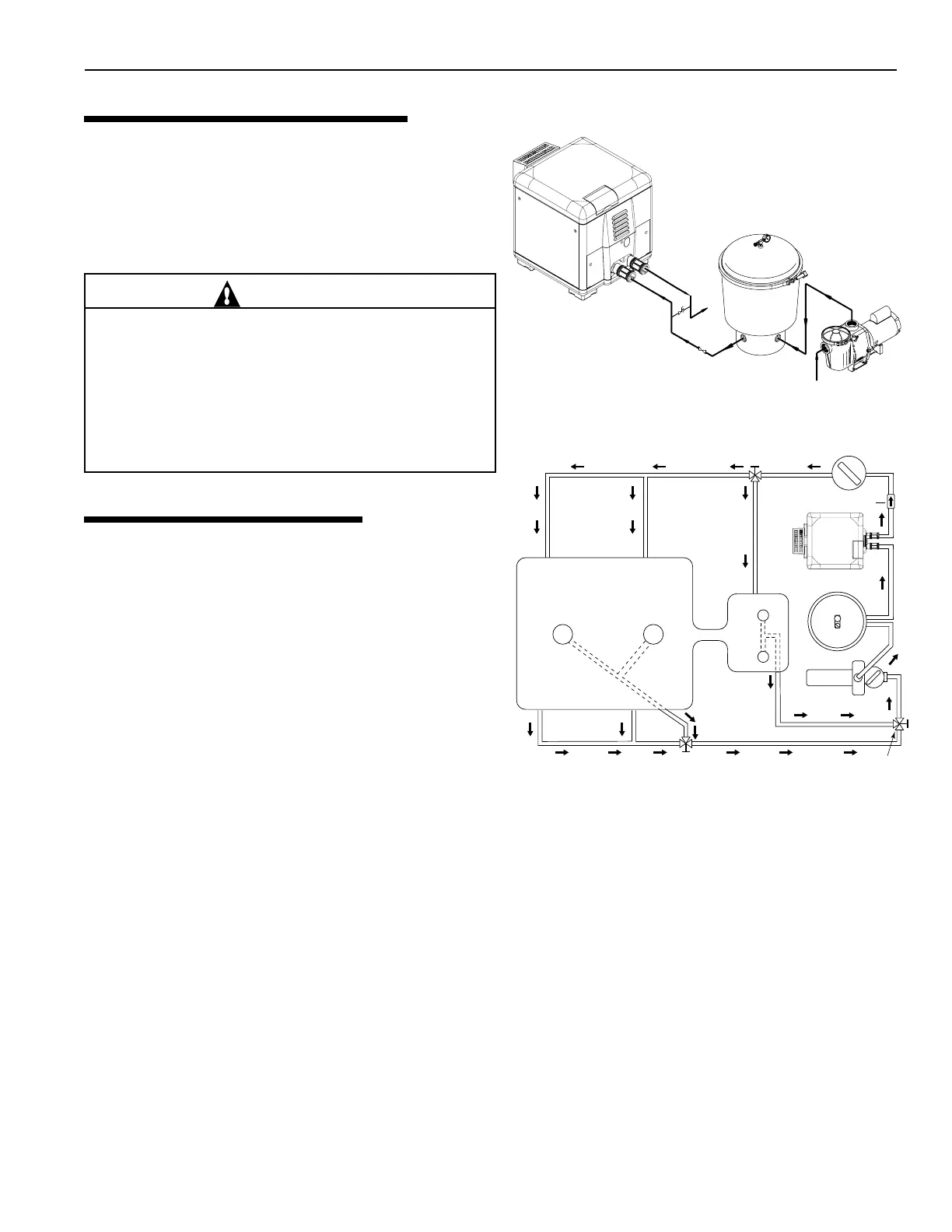

PLUMBING CONNECTIONS

The MasterTemp

125 heater has the capability of direct PVC

pipe plumbing connections. A set of bulkhead ttings is

included with the MasterTemp 125 heater to insure conformity

with Pentair’s recommended PVC plumbing procedure. Other

plumbing connections can be used. See Figure 3 for plumbing

connections.

CAUTION

Before operating the heater on a new installation, turn on

the circulation pump and bleed all the air from the filter

using the air relief valve on top of the filter. Water should

flow freely through the heater. Do not operate the heater

unless water in the pool/spa is at the proper level. If a

manual by-pass is installed, temporarily close it to insure

that all air is purged from the heater.

WATER CONNECTIONS

The heater requires proper water ow and pressure for its

operation. See Figure 4 for the recommended installation. The

lter pump discharges to the lter, the lter discharges to the

heater, and the heater discharges directly to the pool or spa.

A manual bypass valve should be installed across the heater

when the pump flow exceeds 454 L/m (120 GPM). See

“WATER FLOW RATE” on page 5 - Table 1 for setting of

the manual by-pass valve.

Make sure that the outlet plumbing from the heater contains no

shut-off valves or other ow restrictions that could prevent ow

through the heater (except if the heater is below the level of the

pool/spa; as noted below, or winterizing valves where needed).

To switch ow between the pool and spa, use a diverter valve.

Do not use any valve that can shut off the ow. Do not use a

shut-off valve to isolate the heater unless it is below the level of the pool or spa.

Install the chemical feeder downstream of the heater. Install a chemical resistant one-way check valve between the heater

and the chemical feeder to prevent back-siphoning through the heater when the pump is off.

NOTICE: If the heater is plumbed in backwards, it will cycle continuously. Make sure piping from lter is not

reversed when installing heater.

Connect the heater directly to 50 mm (1.5 in - UK) PVC pipe, using the integral unions provided. Heat sinks are not

required. The low thermal mass of the heater will prevent overheating of the piping connected to the pump even if the

heater shuts down unexpectedly. Occasionally a two-speed pump will not develop enough pressure on the low speed to

operate the heater. In this case, run the pump at high speed only to operate the heater. If this does not solve the problem,

do not try to run the heater. Instead, correct the installation.

Do not operate the heater while an automatic pool cleaner is also operating. If the circulation pump suction is plugged

(for example by leaves), there may not be adequate ow to the heater. Do not rely on the pressure switch in this case.

If European Standard Codes of Practice require the installation of a pressure relief valve (PRV), see page 39 for

“PRESSURE RELIEF VALVE”.

Pool

Main

Drain

Spa

From Pool

3-Way

Valve

3-Way

Valve

3-Way

Valve

Chlorinator

Heater

Pump

Check Valve

Filter

Figure 4.

PUMP

FILTER

HEATER

MANUAL

BY-PASS

TO

POOL

GATE

VALVE

FROM

POOL

FROM

FILTER

Figure 3.

Section 1. Installation

Loading...

Loading...