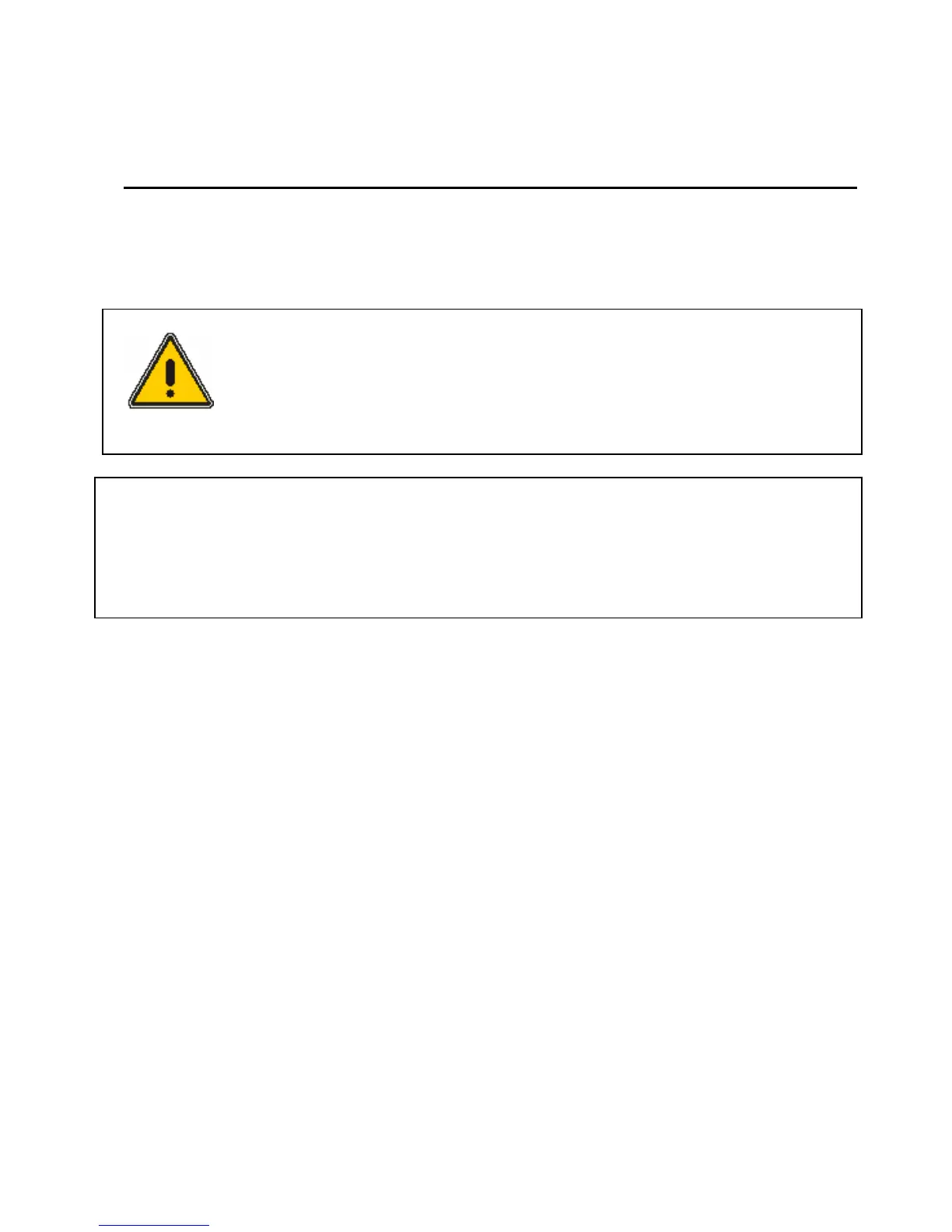

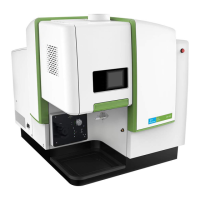

Clarus 500 GC Installation Guide

69

Common Injector/Detector Gas Connections

Figures 13 through 21 shows how gases are connected to the Clarus 500 GC in several

common injector/detector configurations. Note that the strain relief, which is required on all

gas lines, is not shown in these figures.

WARNING

Position incoming gas lines away from the oven exhaust duct so that the hot

exhaust will not blow directly on the gas lines.

CAUTION

Thoroughly purge the incoming gas lines before measuring and adjusting the

gases. This is especially important when using hydrogen gas.

NOTE: For Clarus 500 GC’s that have a combination of both PPC and manual pneumatics, set the

detector gas delivery pressure between 60 and 90 psig and install the fixed 30-psig stainless

steel diaphragm regulator (P/N N610-1473), behind the Clarus 500 GC for the manual

pneumatics detector gases.

The manual pneumatics bulkhead always contains Swagelok nuts in all six locations whether

or not there is an injector or a detector connected to this bulkhead. The PPC modules will be

installed only if your Clarus 500 GC has been configured with PPC for an injector and/or

detector.

The Clarus 500 GC can be configured as any of the following:

• All zones (injector/detector) as PPC.

• All zones as manual pneumatics.

Loading...

Loading...