18 KENR6908

Troubleshooting Section

i02835325

Engine Wiring Information

The wiring schematics are revised periodically.

Thewiringsche

matics will change as updates are

made to the machine harness. For the most current

information, always check the revision number of the

schematic. Us

e the schematic with the latest revision

number.

Harness Wire Identification

Perkins iden

tifies all wires with eleven solid colors.

The circuit number is stamped on the wire at a 25 mm

(1 inch) spacing. Table 4 lists the wire colors and the

color codes.

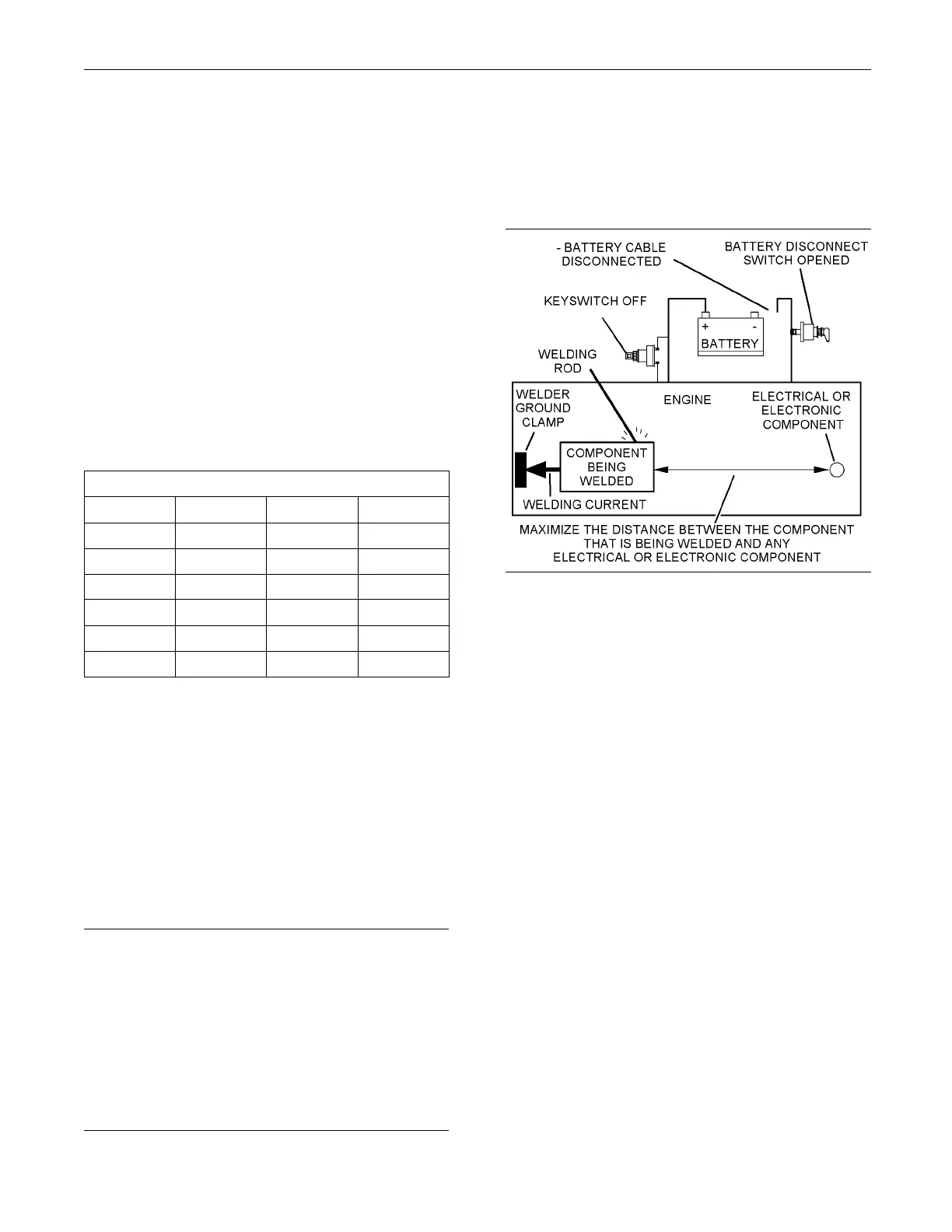

Table 4

Color Codes for the Harness Wire

Color Code Color Color Code Color

BK Black

GN Green

BR Brown BU Blue

RD Red PU Purple

OR Orange GY Gray

YL Yellow WH White

PK Pink

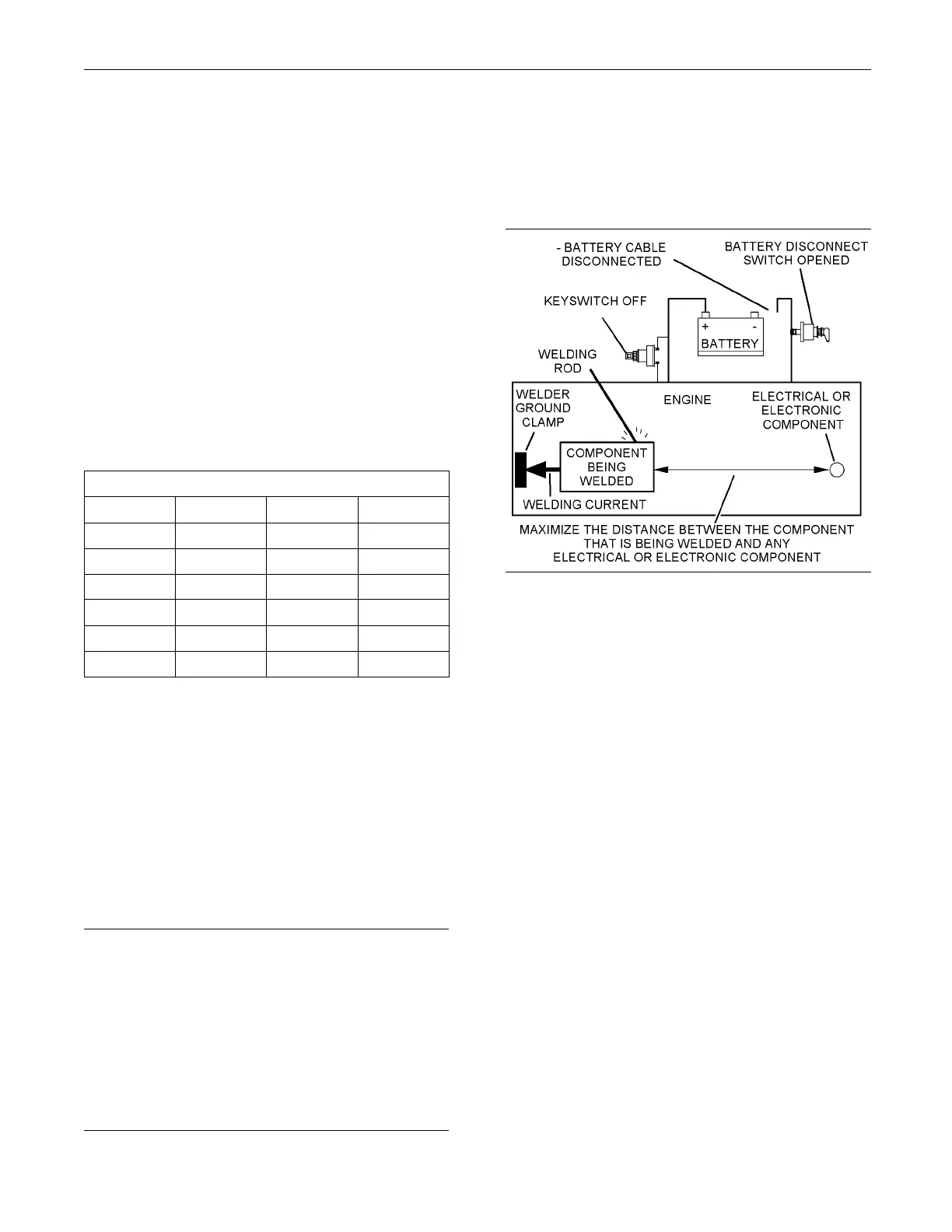

Weldingona

Machine that is Equipped

with an Electronic Control System (ECM)

Proper weld

ing procedures are necessary in o rder

to avoid damage to the engine’s electronic control

module, sensors, and associated components. The

component

that requires welding should be removed.

When welding on a machine that is equipped with an

ECM and removal of the component is not possible,

the follow

ing procedure must be followed. This

procedure provides the minimum amount of risk to

the electronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding can

cause damage to the drive train bearings, hydraulic

components, electrical components, and other com-

ponents.

Clamp the ground cable from the welder to the com-

ponent that will be welded. Place the clamp as close

as possible to the weld. This will help reduce the pos-

sibility of damage.

1. Stop the engine. Turn the keyswitch to the OFF

position.

2. Disconnect the negative battery cable from the

battery. If a b

attery disconnect switch is installed,

open the switch.

g01143634

Illustration 7

Service w elding gu ide (typical diagram )

3. Connect the welding ground cable as close

as possible to the area that will be welded.

Components which may be damaged by welding

include bearings, hydraulic components, and

electrical/electronic components.

4. Protect the wiring harness from welding debris

and from spatter.

5. Weld the materials by using standard welding

methods.

This document has been printed from SPI². Not for Resale

Loading...

Loading...