10 KENR6908

Troubleshooting Section

Signal – The signal is a voltage or a waveform that

is used in order

to transm it information typically from

a sensor to the ECM.

Supply Voltag

e–The supply voltage is a continuous

voltage that is supplied to a component in order to

provide the electrical power that is required for the

component to

operate. The power may be generated

by the ECM or the power may be battery voltage that

is supplied by the engine wiring.

System Configuration Parameters – System

configuration parameters are parameters that affect

emissions an

d/or operating characteristics of the

engine.

Tattletale –

Certain parameters that affect the

operation of the engine are stored in the ECM.

These parameters can be changed by use of the

electronic

service tool. The tattletale logs the number

of changes that have been made to the parameter.

ThetattletaleisstoredintheECM.

Timing Calibration – The timing calibration is the

adjustment of an electrical signal. This adjustment is

made in ord

er to correct the timing error between the

camshaft and the engine speed/timing sensors or

between the crankshaft and the engine speed/timing

sensors.

Top Center Position – The top center position refers

to the cra

nkshaft position when the engine piston

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to r

each this point.

Total Tattletale – The total tattletale is the total

number o

f changes to all the parameters that are

stored in the ECM.

Trim Fil

es – Trim files for the injector are downloaded

fromadisktotheECM.TheTrimfiles compensate

for variances in manufacturing of the electronic unit

injecto

r and for the life of the electronic unit injector.

The serial number for the electronic unit injector must

be obtained in order to retrieve the correct trim file.

i02822

902

Electron ic Service Tools

Perkin

s Electronic Service Tools are designed to help

the service technician:

•

Obtain

data.

•

Diagnose faults.

•

Read parameters.

•

Program parameters.

•

Calibrate sens

ors.

Required Servi

ce Tools

The tools that are listed in Table 1 are required in

order to enabl

easervicetechniciantoperformthe

procedures.

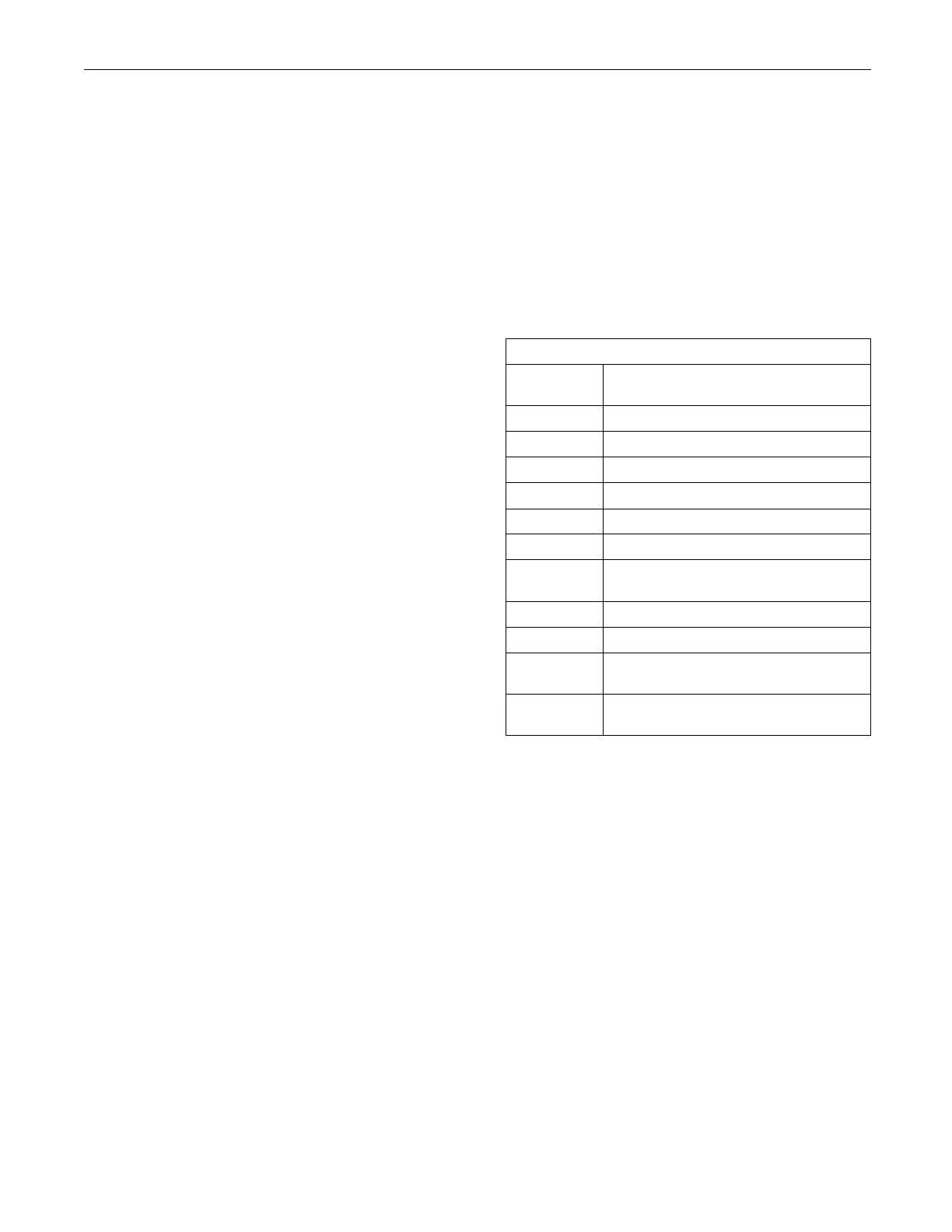

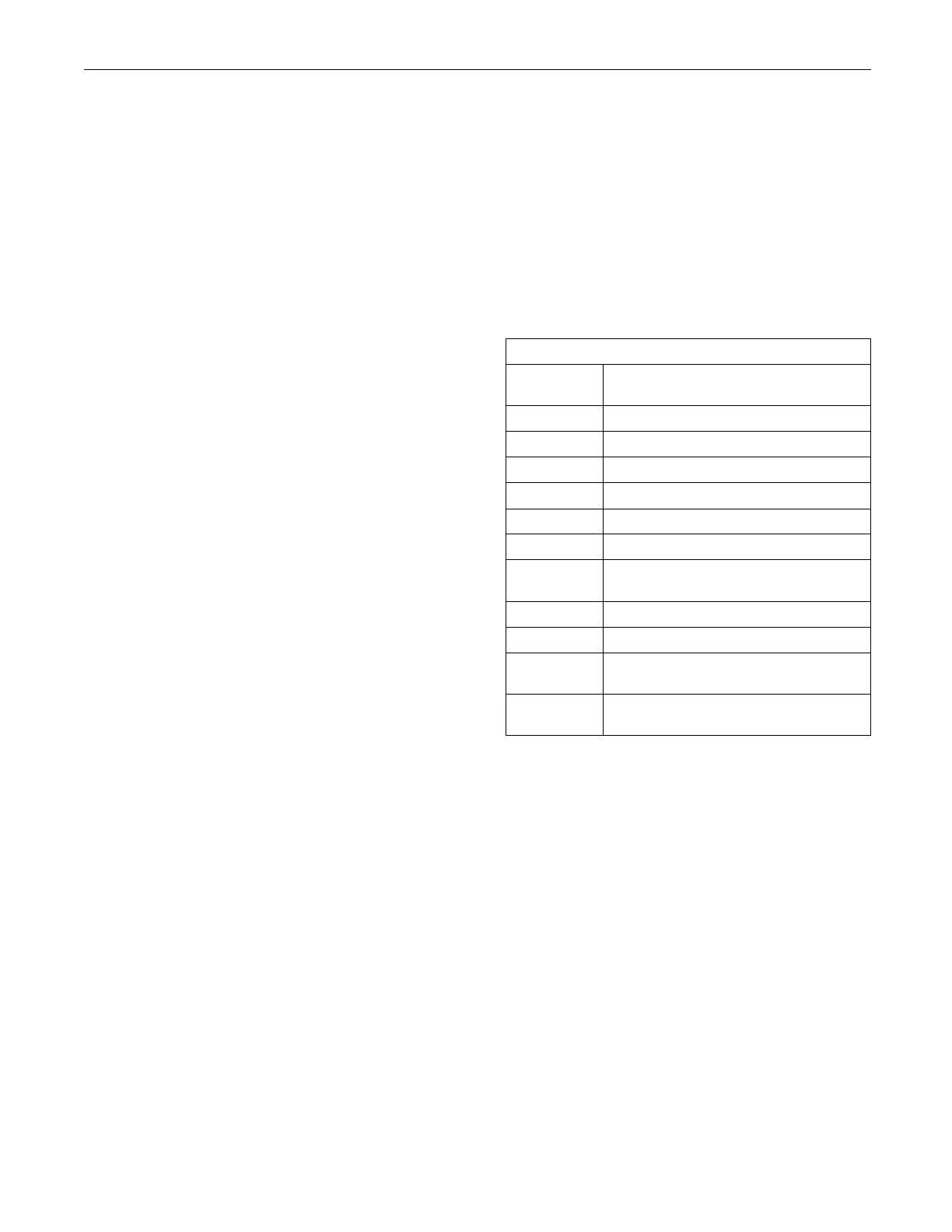

Table 1

Required Service Tools

Part

Number

Description

N/A 4 mm Allen Wrench

GE50038

Transducer

GE50039 Transducer Adapter

GE50040

Cable Assembly

-

Digital Multimeter

GE50042

Multimeter Probes

GE50037

Adapter Cable Assembly (70-PIN

BREAKOUT)

GE50036 Harness ( SERVICE TOOL ADAPTER)

CH11155 CrimpTool(12AWGTO18AWG)

U5MK8195

Connector Harness Repair Kit

(DEUTSCH DT)

U5MK1110

Connector Harness Repair Kit

(AMPSEAL)

Two short jumper wires are needed to check the

continuity of some wiring harness circuits by shorting

two adjacen

t terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

Perkins Electronic Service Tool

(EST)

The Perkin

s EST can display the following

information:

•

Paramete

rs

•

Event codes

•

Diagnostic codes

•

Engine con

figuration

The Perkins EST can be used by the technician to

perform t

he following functions:

This document has been printed from SPI². Not for Resale

Loading...

Loading...