Test the Service Indicator

Service indicators are important instruments.

• Check for ease of resetting. The service indicator

should reset in less than three pushes.

• Check the movement of the service indicator core

when the engine is run at full load speed. The core

should latch approximately at the greatest vacuum

that is attained.

If the service indicator does not reset easily, or if the

core does not latch at the greatest vacuum, the

service indicator should be replaced. If the new

service indicator will not reset, the hole for the service

indicator may be plugged.

If necessary, replace the service indicator more

frequently in environments that are severely dusty.

Replace the service indicator annually regardless of

the operating conditions. Replace the service

indicator when the engine is overhauled, and

whenever major engine components are replaced.

Note: When a new service indicator is installed,

excessive force may crack the top of the service

indicator. Tighten the service indicator to a torque of

2 N·m (18 lb in).

i06759592

Engine Crankcase Breather -

Clean

NOTICE

Perform this maintenance with the engine stopped.

If the crankcase breather is not maintained regularly,

the crankcase breather will become plugged. A

plugged crankcase breather will cause excessive

crankcase pressure that may cause crankshaft seal

leakage.

2806C Crankcase Breather

1. Remove the valve cover. Refer to Disassembly

and Assembly, “Valve Mechanism Cover -

Remove and Install”.

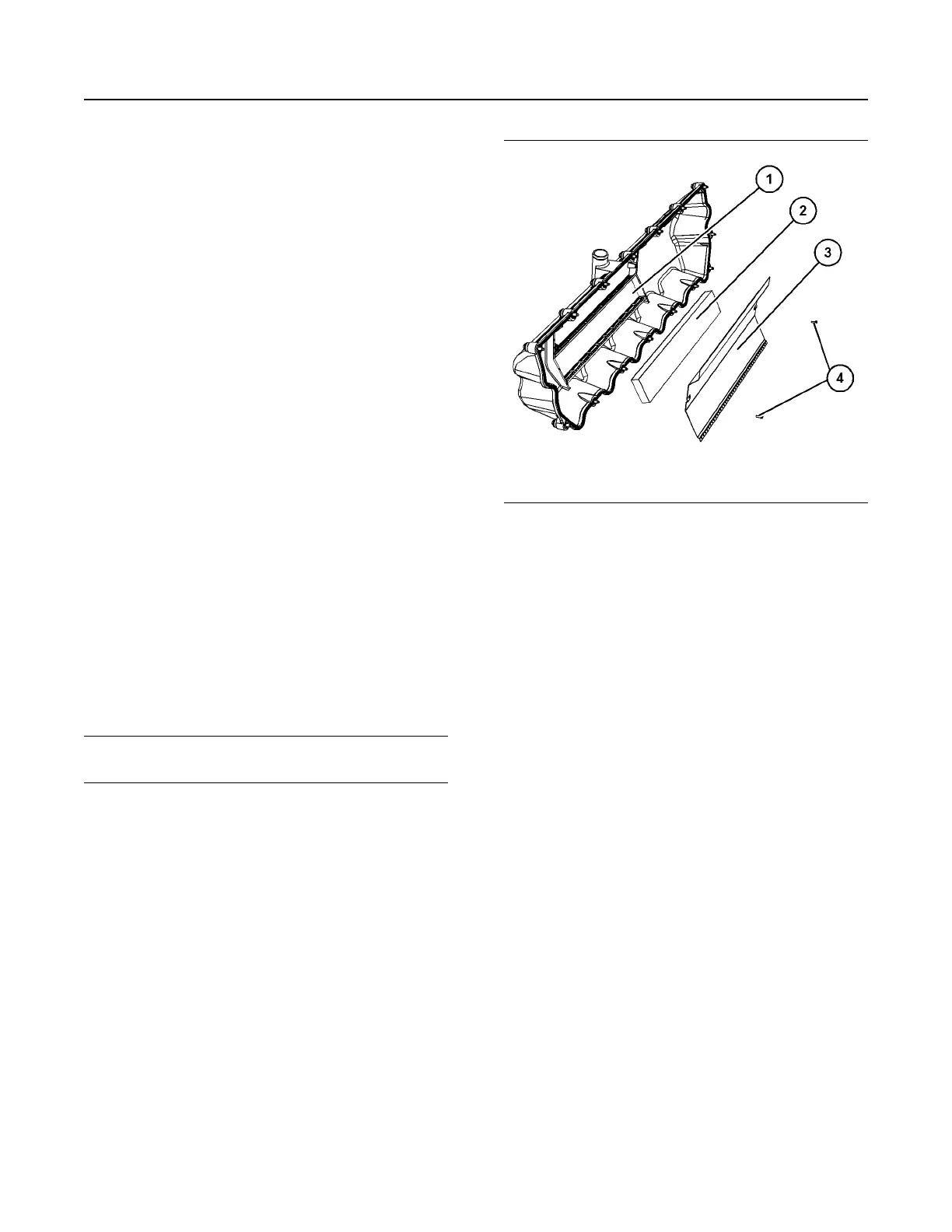

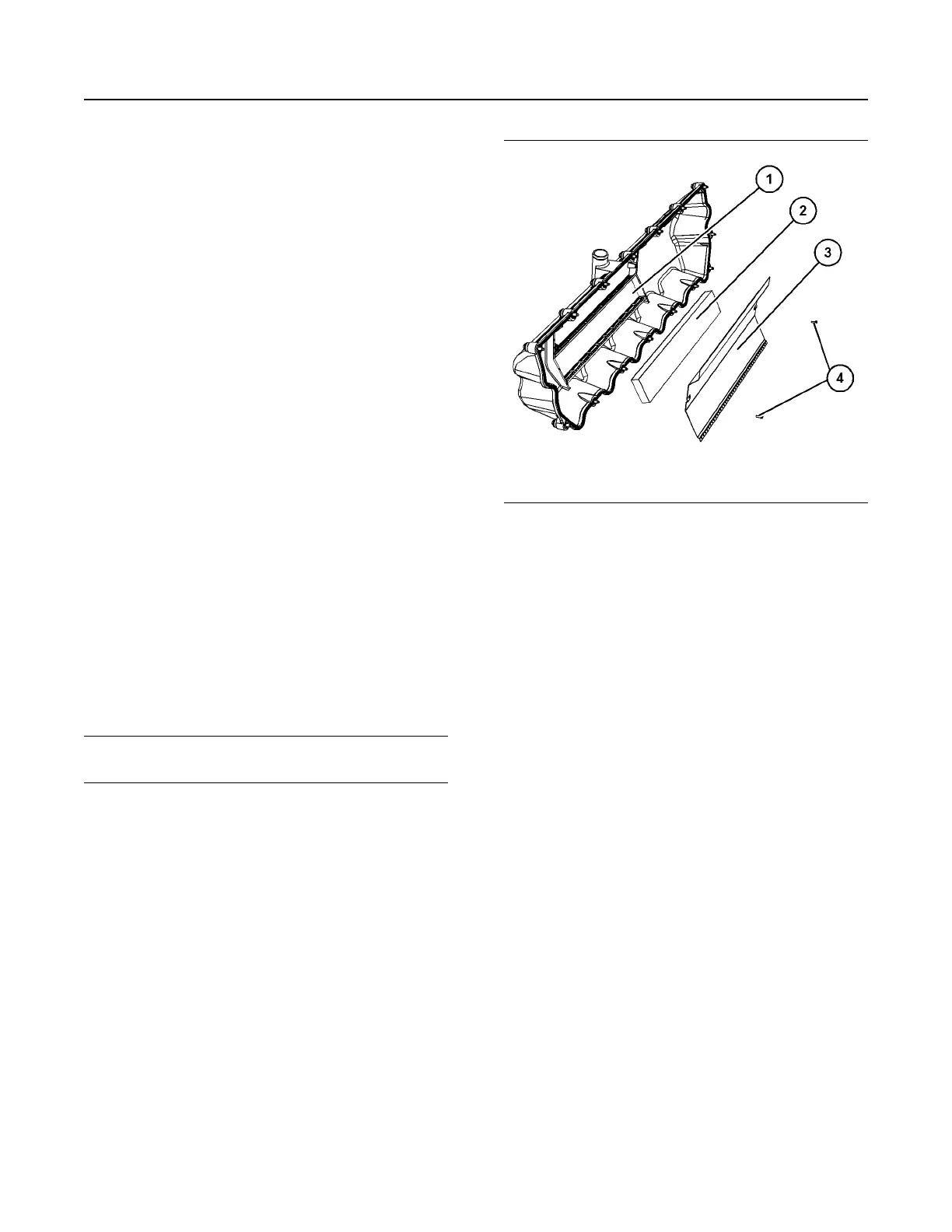

Illustration 54 g06109754

Typical example

2. Remove screws (4) from mechanism cover (1).

3. Remove cover plate (3) from mechanism cover (1)

and remove breather element (2).

4. Wash the breather element (2) in solvent that is

clean and nonflammable. Allow the breather to

dry. Before installation, check for damage to

element and replace element if necessary. Ensure

that the cover plate (3) is clean dry and free from

dirt.

5. Install breather element (2) into mechanism cover

(1). Install screws (4) into cover plate (3) and

install plate assembly to mechanism cover.

6. Tighten screws (4) to a torque of 1.7 N·m

(15 lb in).

7. Install the valve cover. Refer to Disassembly and

Assembly, “Valve Mechanism Cover - Remove

and Install”.

i07819538

Engine Mounts - Inspect

Note: The engine mounts may not have been

supplied by Perkins. Refer to the Original Equipment

Manufacturer (OEM) information for further details on

the engine mounts and the correct bolt torque.

Inspect the engine mounts for deterioration and for

correct bolt torque. Excessive engine vibration can

be caused by the following conditions:

90

SEBU9074-06

Maintenance Section

Engine Crankcase Breather - Clean

Loading...

Loading...