Pfaff360

The sewing

hook

of

the Pfaff 360 is timed

in

the same

way

as

the Pfaff 260

hook.

It

should be kept

in

mind, however,

that

the sewing

hook

of

the Pfaff 360

is

mounted permanently on the short transverse shaft

and,

hence, cannot

be

turned

in

setting the needle

bar

rise. For this reason, to time the sewing hook,

loosen the lower driving belt sprocket

and

rotate the long hook drive shaft ac-

cordingly.

Under no circumstances must the position

of

the

upper

driving belt

sprocket

be changed on the arm shaft. Although this procedure would

be

much

simpler, it would disturb the balance

of

this shaft.

The set screws on the

lower driving

belt

sprocket con

be

reached through

one

of

the

apertures

at

the bock

of

the machine base. For a better view

of

the ports

to be adjusted

,.

remove gri

ll

e 8

(Fig.

83).

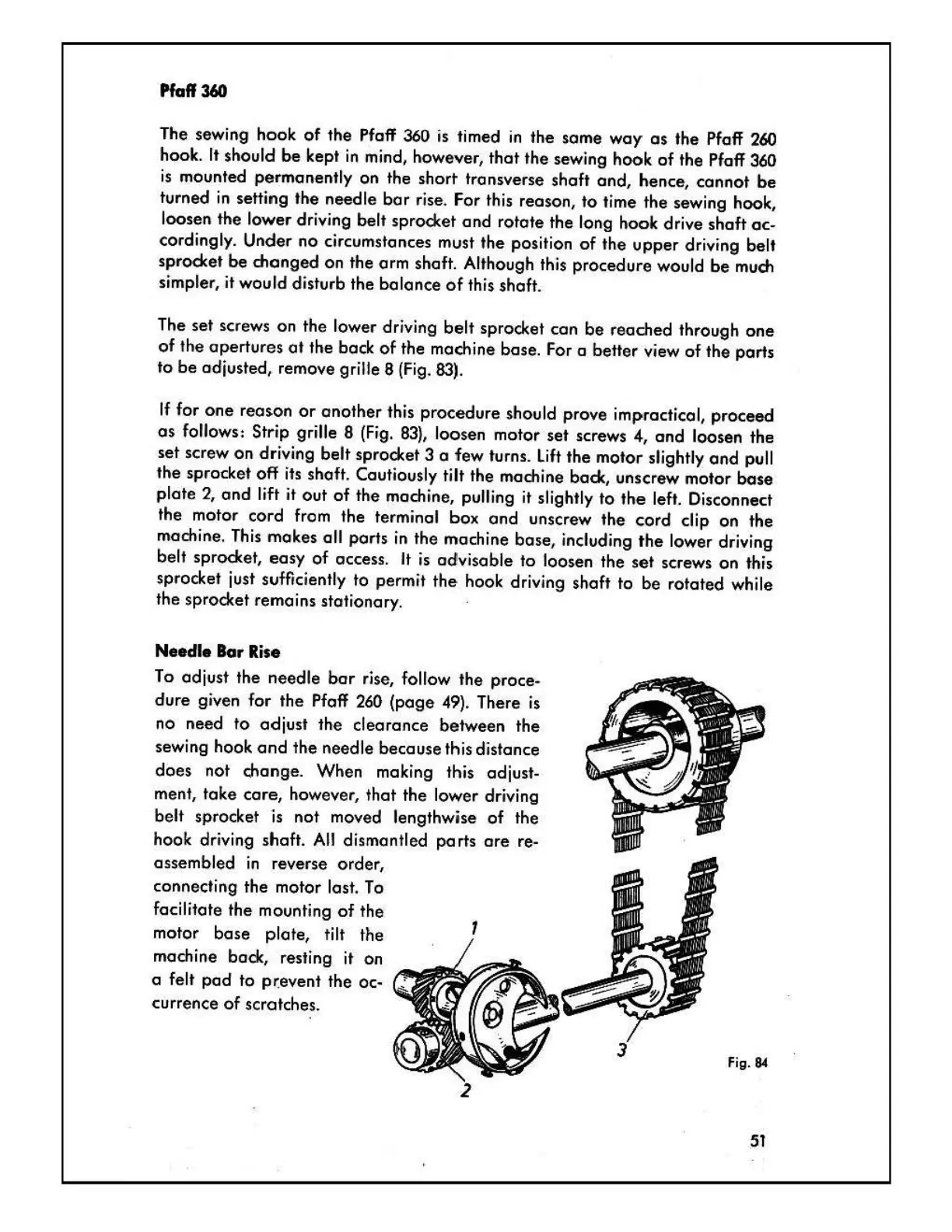

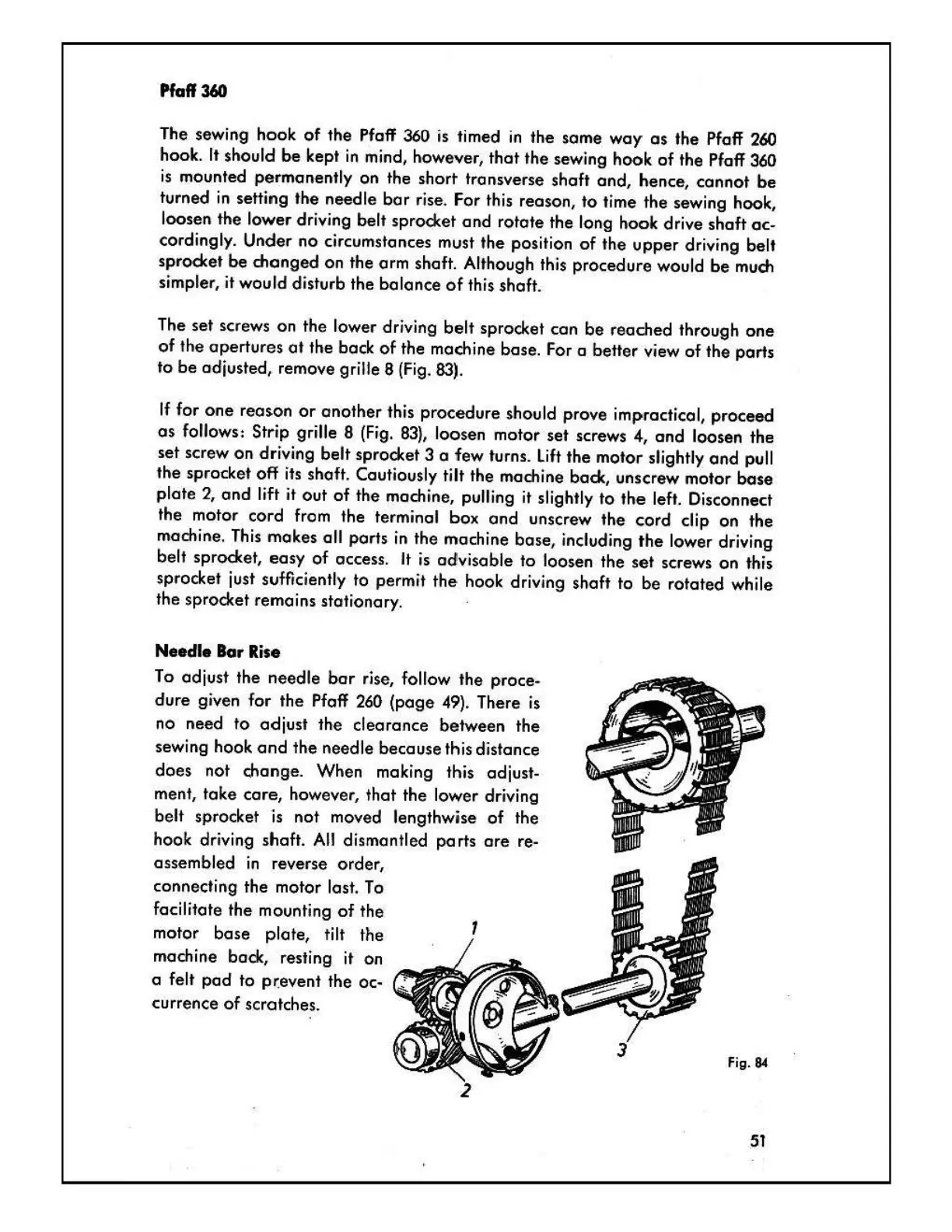

If

for

one

reason

or

another

this procedure should prove impractical, proceed

as

follows: Strip grille 8

(Fig.

83),

loosen motor set screws 4,

and

loosen the

set screw on driving

belt sprocket 3 a few turns. lift the motor slightly

and

pull

the sprocket off its shaft. Cautiously tilt the machine back, unscrew motor

base

plate 2,

and

lift it out

of

the machine, pulling it slightly to

the

left. Disconnect

the motor cord from the

terminal box

and

unscrew the

cord

clip on the

machine.

This

makes all ports

in

the machine bose, including

the

lower driving

belt sprocket,

easy

of

access. It is advisable to loosen the set screws on this

sprocket just

sufficiently to permit

the

hook driving shaft to be

rotated

while

the sprocket remains stationary.

Needle

Bar

Rise

To

adjust the needle

bar

rise, follow

the

proce-

dure given for the Pfaff 260

(page

49). There is

no need to adjust

the

clearance between

the

sewing hook

and

the needle because this distance

does

not change. When making this adjust-

ment, toke

care,

however, that

the

lower driving

belt sprocket

is

not

moved lengthwi

se

of

the

hook

dr

iving shaft.

All

dismantled ports

are

re-

assembled

in

reverse order,

connecting the motor

lost. To

facilitate the mounting

of

the

motor

base

plate, tilt the

machine back, resting it on

o

felt

pad

to p(event the oc-

currence

of

scratches.

Fig.

84

.

51

Loading...

Loading...