1

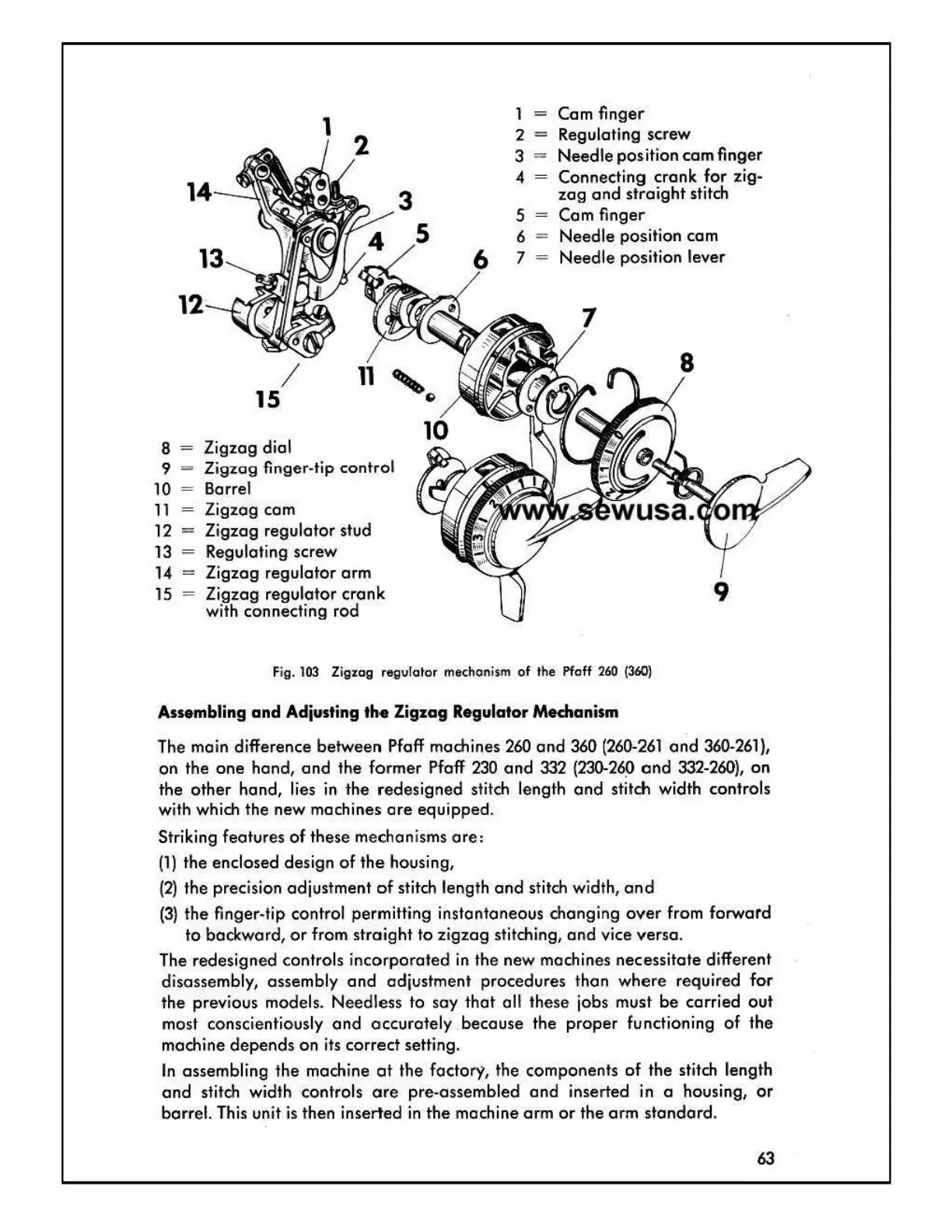

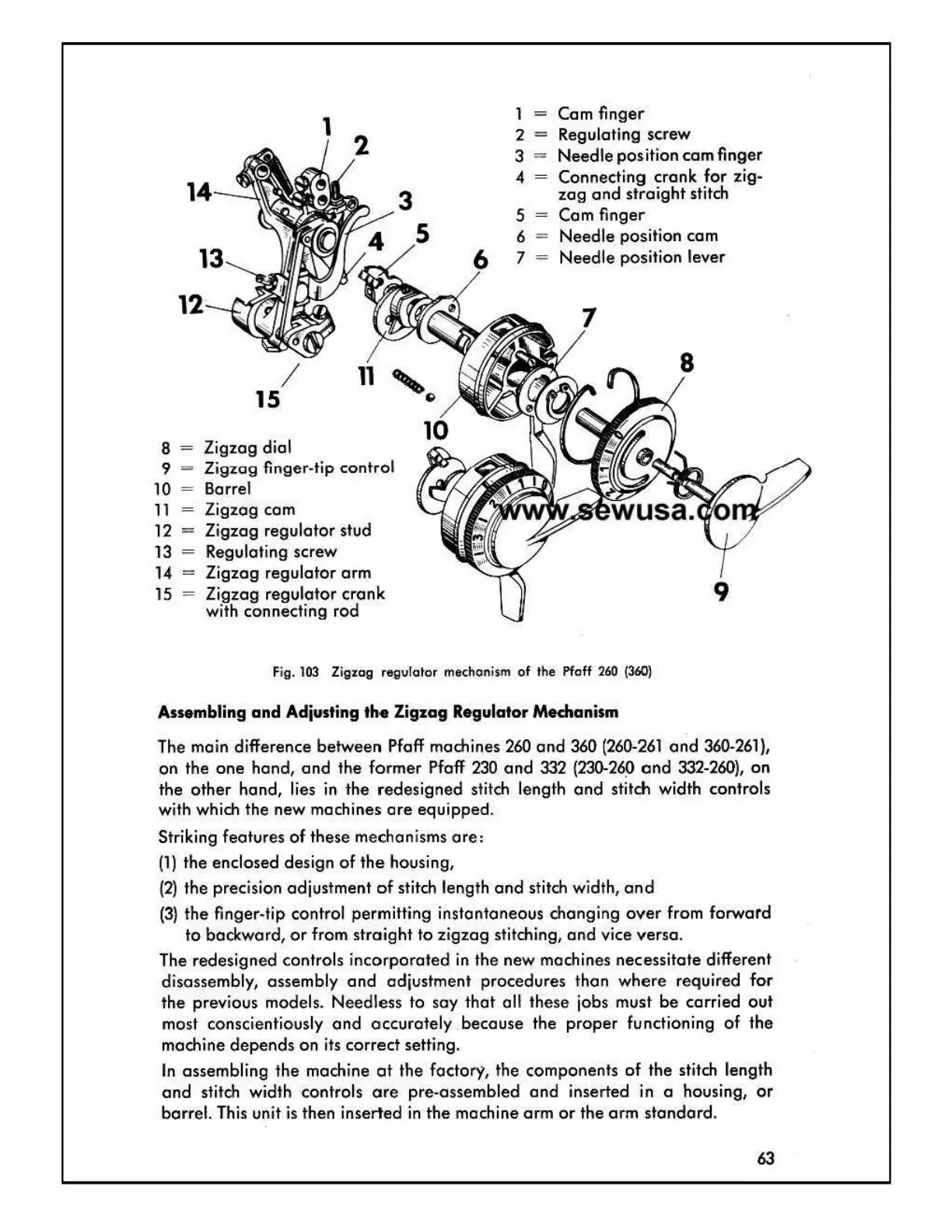

1 - Cam finger

Regulating screw

2 -

3 =

4

Needle

position

cam

finger

Connecting

crank

for

zig-

zag

and

straight

stitch

12

8 Zigzag dial

9 Zigzag finger-tip control

10 Barrel

11

Zigzag com

12

- Zigzag regulator stud

13

Regulating screw

14 = Zigzag regulator

arm

15 Zigzag regulator

crank

with connecting rod

5

= Cam

fi

nger

6 =

Needle

position cam

7

-

Needle

position lever

Fig.

103

Zigzag regulator mechanism

of

the pfaff

260

(360)

Assembling and Adjusting the Zigzag Regulator Mechanism

The main difference between Pfaff machines

260

and

360

(260-261

and

360-261},

on

the

one

hand,

and

the former Pfaff

230

and

332

(230-269

ond

332-260},

on

the

other

hand, lies

in

the

redesigned

stitch length

and

stitch width controls

with which the new machines

are

equipped.

Striking features

of

these mechanisms

are:

(1)

the enclosed design

of

the

housing,

(2)

the precision adjustment

of

stitch leng

th

and

stitch width,

and

(3)

the finger-tip control permitting instantaneous changing

over

from forward

to backward,

or

from

straight

to

zigzag

stitching,

and

vice versa.

The redesigned controls inc

orpo

rated

in the new machines nec·essitate different

disassembly, assembly

and

adjustment procedures than

where

required for

the previous models. Needless to soy

that

all these jobs must

be

carried

out

most conscientiously

and

accu

rately .

because

the

proper

functioning

of

the

machine

depends

on

its

correct

setting.

In

assembling the machine

at

the factory, the components

of

the stitch length

and

stitch width controls

ore

pre-assembled

and

inserted in a housing,

or

barrel. This unit is then inserted

in

the

machine

arm

or

the

arm

standard.

63

Loading...

Loading...