If

they

are

positioned

as

shown in Fig. 89-1, loosen

the

two

feed

dog

set

screws

and

adjust.

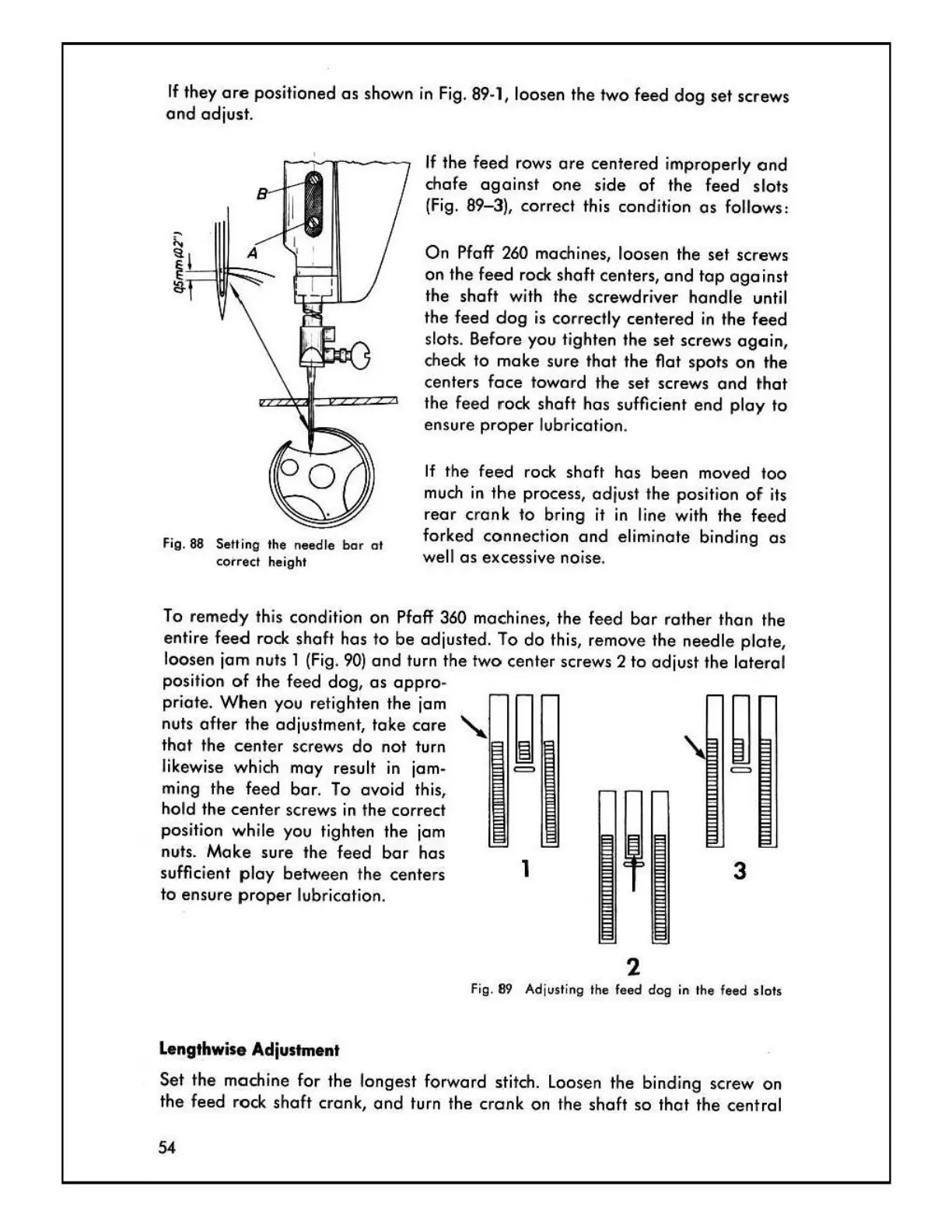

Fig. 88 Setting the needle

bar

of

correct height

If

the

feed

rows

are

centered

improperly

and

chafe

against

one

side

of

the

feed

slots

(Fig. 89-3), correct this condition

as

follows:

On

Pfaff 260 machines, loosen

the

set

screws

on

the

feed

rock

shaft

centers,

and

top

against

the

shaft

with

the

scr

ewdr

iver

handle

until

the

feed

dog

is

correctly

centered

in

the

feed

slots. Before you tighten

the

set

screws

again,

check

to

make

sure

that

the

Aot

spots

on

the

centers

face

toward

the

set

screws

and

that

the

feed

roc

k

shaft

ha

s sufficient

end

p

loy

to

ensure

proper

lubrication.

If

the

feed

rock

shaft

has

been

moved

too

much in

the

process,

adjust

the

position

of

its

rear

crank

to

bring it

in

line with

the

feed

forked

connect

ion

and

eliminate binding

as

well

as

excessive noise.

To

remedy

this condition

on

Pfaff 360 machines,

the

feed

bar

rather

than

the

entire

feed

rock

shaft

has

to

be

adjusted.

To

do

this, remove

the

needle

plote,

loosen

jam

nuts 1

(F

ig.

90)

and

turn

the

two

center

screws 2

to

adjust

the

latera

l

position

of

the

feed

dog,

as

appro-

priate.

When

you retighten

the

jam

nuts

after

the

adjustment,

take

care

that

the

center

screws

do

not

turn

likewise which may result in jam-

ming

the

feed

bar.

To

avoid

this,

hold

the

center

screws in

the

correct

position while you tighten

the

jam

nuts.

Make

sure

the

feed

bar

has

sufficient

play

between

the

centers

to

ensure

proper

lubrication.

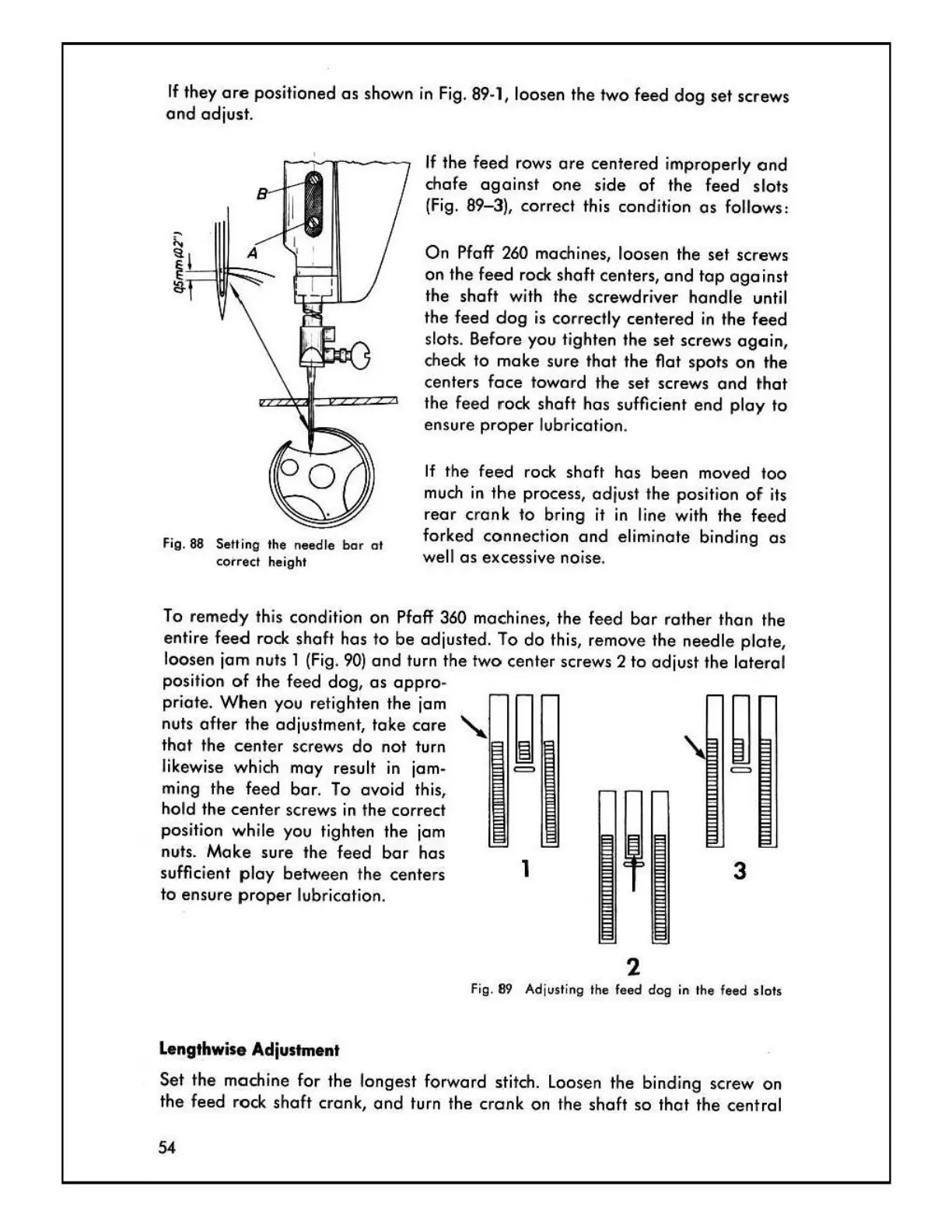

Lengthwise

Adjustment

=

1

3

2

Fig. 89 Adjusting the feed dog

in

the feed slots

Set

the

machine

for

the

longest

forward

stitch. Loosen

the

binding screw on

the

feed

rock

shaft

crank,

and

turn

the

crank

on

the

shaft

so

that

the

central

54

Loading...

Loading...