Power consumption

≤16 W

Fuse to be connected

1)

≤1.25 AT

Voltage at the supply unit with

maximum cable length

21

… 28 VDC

(max. ripple. 2 V

pp

)

Electrical connection Hirschmann compact

connector GO 6,

6 contacts, male

Cable 5 poles plus screening

Cable length max. 35 m (0.25 mm² conductor)

50 m (0.34 mm² conductor)

100 m (1.0 mm² conductor)

Grounding concept → Figure 1

Materials on the vacuum

side

housing, supports,

screens

feedthrough

isolator

cathode

cathode holder

Pirani element

stainless steel

NiFe nickel plated

glass

iridium, yttrium oxide

molybdenum

tungsten, copper

Internal volume

DN 25 ISO-KF

DN 40 ISO-KF

DN 40 CF-R

≤ 24 cm

3

≤ 24 cm

3

≤ 34 cm

3

Pressure max. 2 bar (absolute)

Admissible temperatures

storage

operation

bakeout

–20 °C ... +70 °C

0 °C … +50 °C

150 °C (without electronics

unit or with extension)

Relative humidity

year’s mean

during 60 days

≤ 65% (no condensation)

≤ 85% (no condensation)

Use indoors only

altitude up to 2000 m

Type of protection IP 30

Dimensions [mm]

DN 25 KF

DN 40 KF

DN 40 CF-R

Weight 285 g (Flansch DN 25 ISO-KF)

315 g (Flansch DN 40 ISO-KF)

550 g (Flansch DN 40 CF-R)

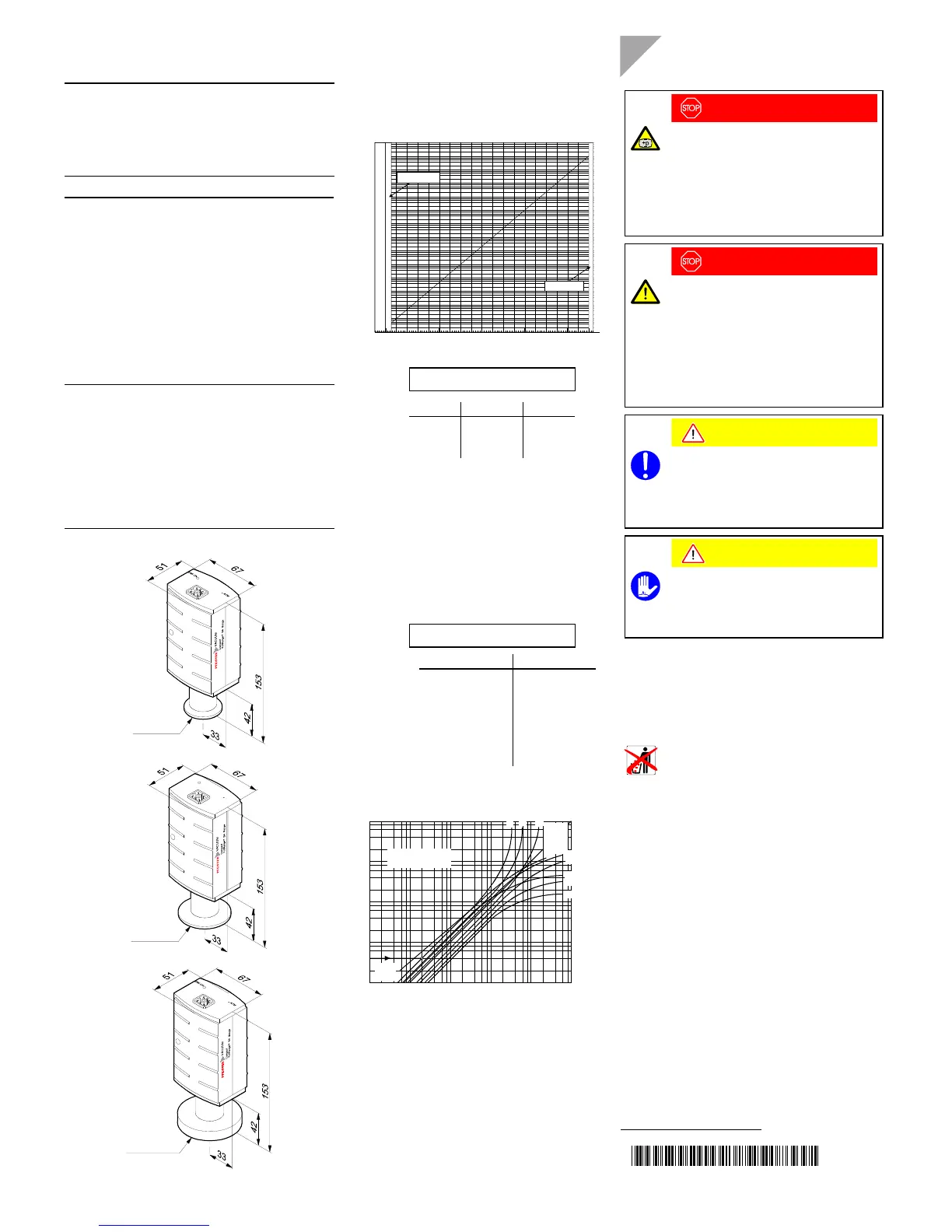

Measuring Signal vs. Pressure

Sensor error

overrange

underrange

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

1E+01

1E–01

1E–03

1E–05

1E–07

1E–09

1E+03

1E+04

1E+02

1E+00

1E–02

1E–04

1E–06

1E–08

1E–10

0.0

Measuring signal U[V]

Pressure p [mbar]

p = 10

(U-7.75)/0.75+c

Upc

[V] [mbar] 0

[V] [Pa] 2

[V] [Torr] -0.125

where valid in the range

p pressure

U measuring signal

c constant (pressure unit

dependent)

0.774 V

≤ U ≤ 10.000 V

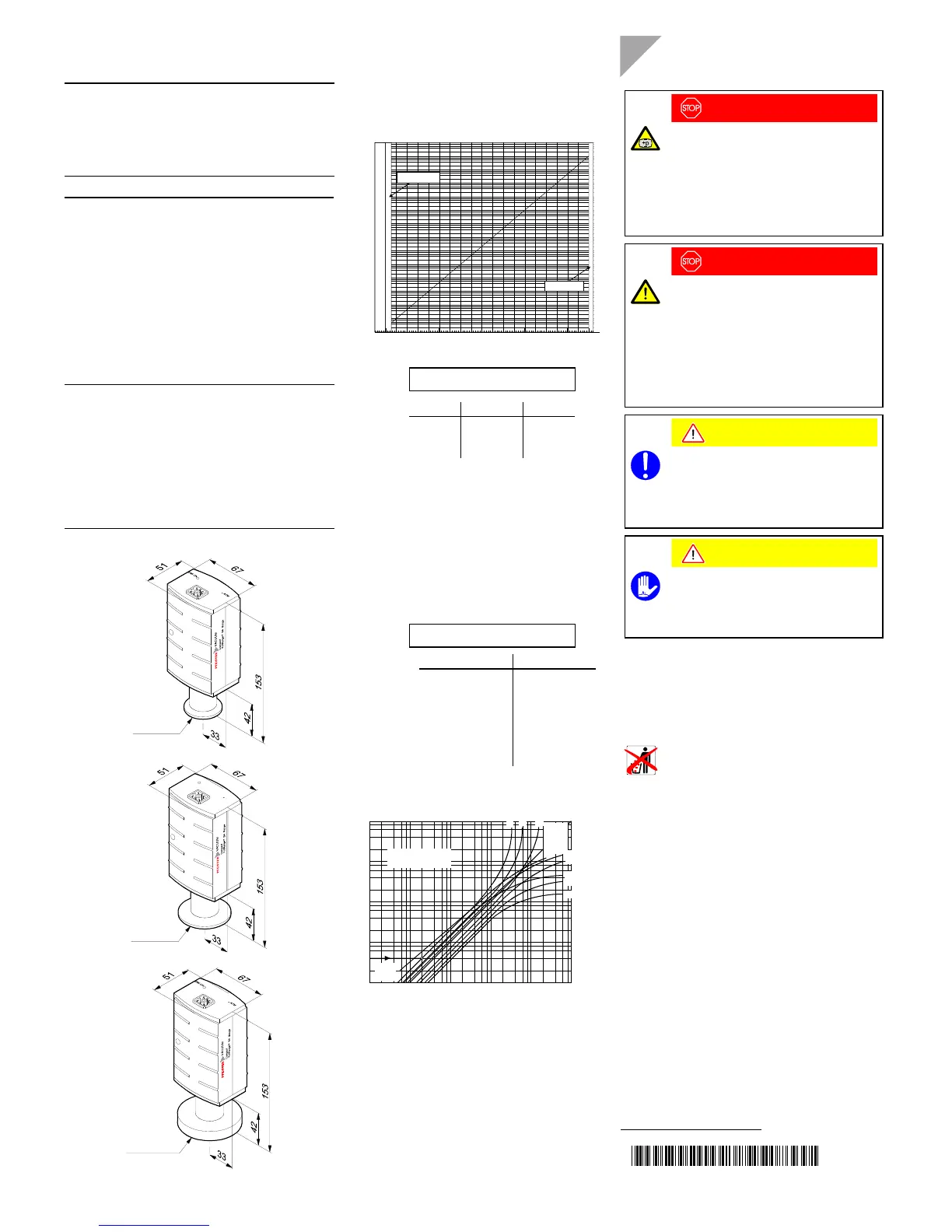

Gas Type Dependence

Hot cathode range

For gases other than air, the pressure in the indication range

p < 10

-3

mbar can be determined by a simple conversion:

p

eff

= K × indicated pressure

where Gas type K (mean)

Air (N

2

, O

2

,

CO) 1.0

Xe 0.4

Kr 0.5

Ar 0.8

H

2

2.4

Ne 4.1

He 5.9

Pirani range

10

2

8

6

4

2

p (mbar)

p

eff

(mbar)

H

2

He

Ne

Xe

Kr

Ar

Freon 12

Luft / Air

O2

CO

N

2

10

–3

24

6

10

–2

10

–1

10

0

10

1

10

2

8

24

68

24

68

24

68 2 4 68

Water

vapor

Indication range

above 10

-2

mbar

CO2

10

1

8

6

4

2

10

0

8

6

4

2

10

-1

8

6

4

2

10

-2

Installation

Vacuum Connection

DANGER

Caution: overpressure in the vacuum system

>1 bar

Injury caused by released parts and harm

caused by escaping process gases can result if

clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum sys-

tem is pressurized. Use the type of clamps which

are suited to overpressure.

DANGER

Caution: hazardous voltages

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

The gauge must be electrically connected to the

grounded vacuum chamber. This connection

must conform to the requirements of a protective

connection according to EN 61010:

• CF flanges fulfill this requirement.

• For gauges with a KF flange, use a conduc-

tive metallic clamping ring.

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take

appropriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

The gauge should be mounted so that no vibrations occur.

The gauge may be mounted in any orientation. However, any

particles and condensates present should not be able to

penetrate into the measuring chamber. Install the gauge in

such a way that it need not be removed for adjustment.

Remove the protective lid and install the product to the

vacuum system.

Keep the protective lid.

bg805131be/ a

(2005-10)

Original: German BG 805 131 BD / A (2005-10)

Loading...

Loading...