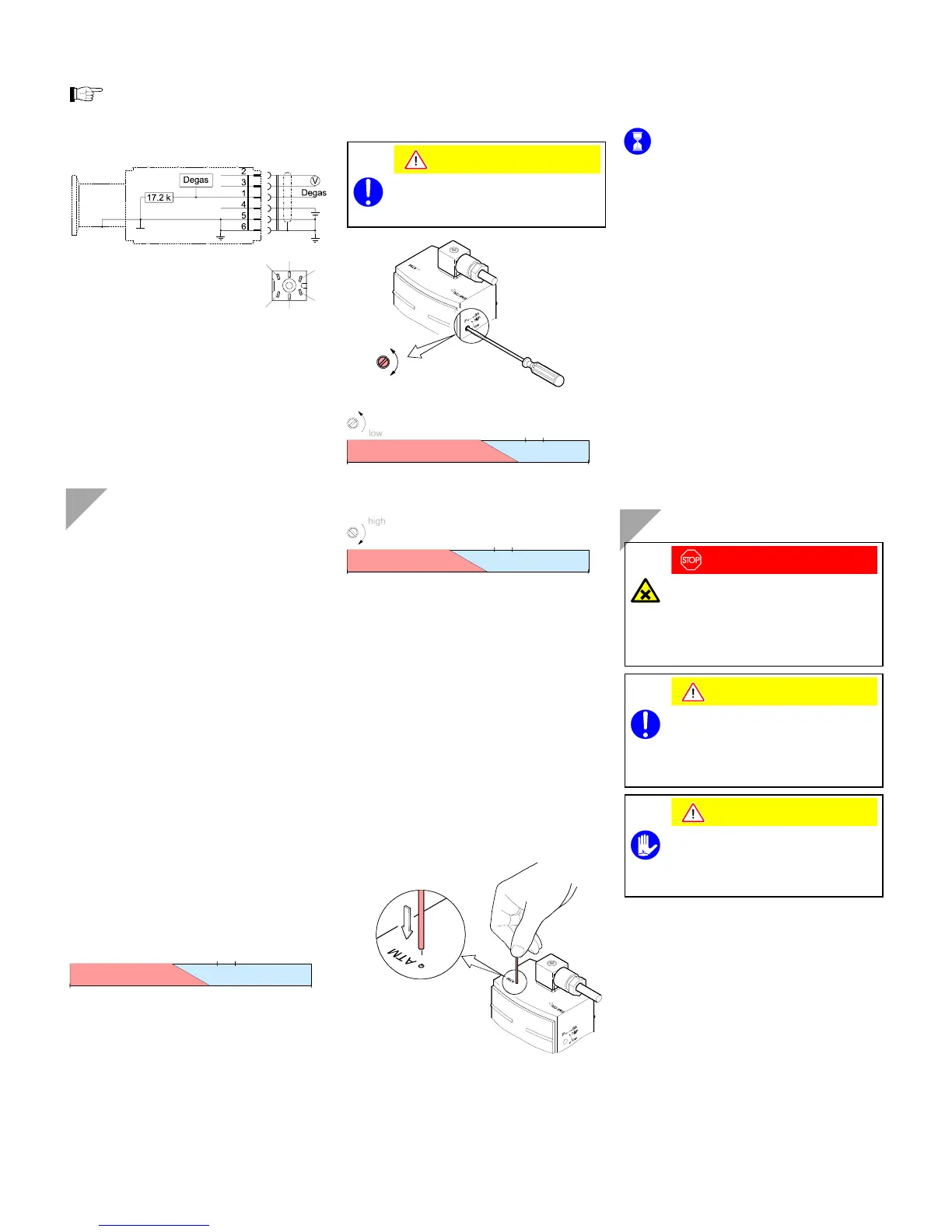

Power Connection

Precondition: Vacuum connection is properly made.

Before connecting or disconnecting the product, turn

off the control system.

If no sensor cable is available, make one according to

the diagram.

–

+

–

+

Figure 1: Electrical connection

Pin 1 a) Degas

b) Identification

(U

≤ 4.25 V)

Pin 2 Signal output

(measuring signal)

Pin 3 Signal common GND

Pin 4 Supply

Pin 5 Supply common GND

Pin 6 Screening

2

5

3

1

6

4

Connector,

soldering side

Connect the signal cable to the gauge and secure it

with the screw.

Connect the gauge to the measurement and control

unit.

Operation

When the voltage is applied, the measuring signal is avail-

able between pins 2 and 3. Over the whole measurement

range, the measuring signal is output as a logarithm of the

pressure (Relationship between measuring signal and pres-

sure

→ "Technical Data").

Allow for a stabilizing time of approx. 10 minutes. Once the

gauge has been switched on, permanently leave it on irre-

spective of the pressure.

Gas Type Dependence

The measurement value is gas dependent. The display ap-

plies to dry air, N

2

, O

2

and CO. For other gases, it has to be

converted (

→ "Technical Data").

If the gauge is operated in connection with a MaxiGauge™

vacuum measurement and control unit, a calibration factor

can be entered for correction of the reading (

→ [2]).

Measurement Range

The PBR 260 covers the measurement range of

5×10

-10

mbar … 1000 mbar.

• The Pirani system continuously monitors the pressure.

• The hot cathode system (controlled by the Pirani) is only

switched on when the pressure drops below the set

threshold (p

on

). The hot cathode will be ready for operation

after a few seconds' heating time, when the <EMI ON>

lamp is lit.

• When the pressure rises above the setpoint (p

off

) the hot

cathode is switched off and the <EMI ON> lamp turns off.

In the upper pressure range, the Pirani reading and in the

lower pressure range, the hot cathode reading is output. In

the overlapping range (p

lower

… p

upper

), a combined signal of

the two measurement systems is supplied:

1000 mbar5 ×

10

-10

mbar

PiraniHot cathode

p

u

p

p

e

r

p

l

o

w

e

r

p

o

n

p

o

f

f

Defining the Switching on/off Range

The PBR 260 has two definable switching on/off ranges with

their corresponding overlapping ranges. The switching on/off

range is selected with the <P

↔ BA> switch and should be

chosen in such a way that it is situated outside the process

pressure range. The positions "high" (default) and "low" are

available. Preferably, "low" should be selected as contamina-

tion of the hot cathode system is reduced at lower pressures.

Caution

The switching on/off range must be selected

before the gauge is activated as the switch

position is polled only when the gauge is

switched on.

high

low

5 ×

10

-10

mbar

5

.

5

×

1

0

-

3

2

.

4

×

1

0

-

2

3

.

2

×

1

0

-

2

2

.

0

×

1

0

-

2

1000 mbar

high

5 ×

10

-10

mbar

2

.

0

×

1

0

-

3

9

.

9

×

1

0

-

3

1

.

3

×

1

0

-

2

8

.

0

×

1

0

-

3

1000 mbar

low

PiraniHot cathode

PiraniHot cathode

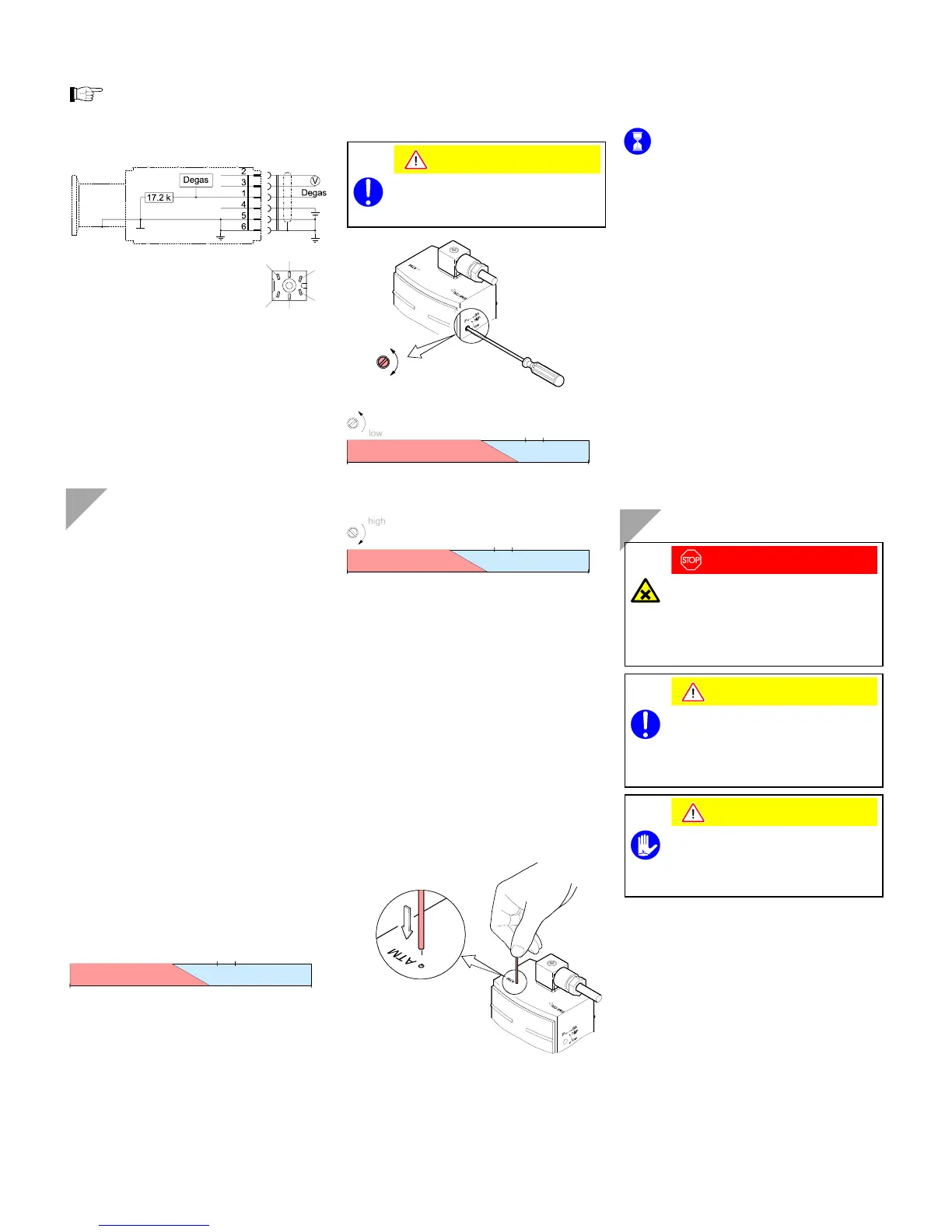

Adjusting the Gauge

The gauge is factory calibrated. If used under different cli-

matic conditions or in a different position, through aging or

contamination, and after exchanging the sensor, the charac-

teristic curve can be offset and readjustment can become

necessary. Only the Pirani element can be adjusted. The hot

cathode system is factory adjusted.

HV adjustment:

At p ≈ 2×10

-3

mbar the Pirani system is automatically adjusted

by the hot cathode.

Adjustment at atmospheric pressure:

Operate the gauge for 10 minutes at atmospheric

pressure. If the gauge was operated within the hot

cathode range, a cooling-down time of approx.

30 minutes is to be expected (gauge temperature =

ambient temperature).

Insert a pin through the opening marked <ATM> and

push the button inside for at least 5 s.

Zero point adjustment:

A zero point adjustment is recommended

• after the sensor has been exchanged

• as part of the usual maintenance work for quality

assurance.

The push button used for the adjustment at atmospheric

pressure is also used for the zero point adjustment.

Operate gauge for approx. 10 minutes at a pressure of

≤1×10

-4

mbar.

Insert the pin through the opening marked <ATM> and

push the button inside for at least 2 s..

The adjustment is done automatically and ends after

2 minutes.

Degas

Deposits on the electrode system of the hot cathode ioniza-

tion gauge can lead to unstable measurement readings.

In such a case it is advisable to start a degas process of the

anode (bakeout) at a pressure below 7.2×10

-6

mbar (5 mA

emission current). Depending on the application, this function

can be activated via a MaxiGauge™ vacuum measurement

and control unit, manually with a switch, or automatically by

the system control (e.g. PLC). The bakeout process is auto-

matically stopped by the PBR 260 after 3 minutes, if it has not

been terminated before.

The degas process is activated when the control signal

(Pin 1) switches from OFF (0 V) to ON (24 V). It is deacti-

vated when the control signal switches from ON (24 V) to

OFF (0 V), or after a maximum of 3 minutes.

For a repeated degas process, the control signal first has to

switch from ON (24 V) to OFF (0 V), to then start the degas

process again with ON (24 V). If the degas function is acti-

vated by the system control, it should be set to OFF again by

the system control after max. 3 minutes of bakeout in order

for an unambiguous operating status to be achieved.

The degas process causes a heating of the electron collector

grid to approx. 700 °C by electron bombardment.

Deinstallation

DANGER

Caution: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take

appropriate measures to ensure cleanliness and

prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Vent the vacuum system.

Turn the gauge off.

Unplug the sensor cable.

Remove the gauge from the vacuum system and install

the protective lid.

Loading...

Loading...