PHI 5000 03 OPERATING LOGIC

1/8

Switching on

When the machine is switched on, the gear motor repositions itself as follows:

- It acts on microswitch 1

- e gear motor changes its rotation direction and moves upwards again by approx. 1-2 mm.

- e boiler begins to heat the water for approx. 45 sec, in order to reach the optimal temperature (established

by the soware).

An NTC is used as a temperature sensor; in the event of overheating this reduces boiler element power

consumption. e electronic system detects the current boiler temperature from the drop in voltage of

the sensor and adjusts it accordingly. Heating element values and corresponding temperatures: see table.

3.2. Temperature sensor (adjustment)

Temp. (°C) R nom (kΩ) ΔR (+/- %)

20 61.465 8.6

50 17.599 5.9

75 7.214 4.1

80 6.121 3.7

85 5.213 3.4

90 4.459 3.1

100 3.3 2.5

125 1.653 3.9

150 0.893 5.1

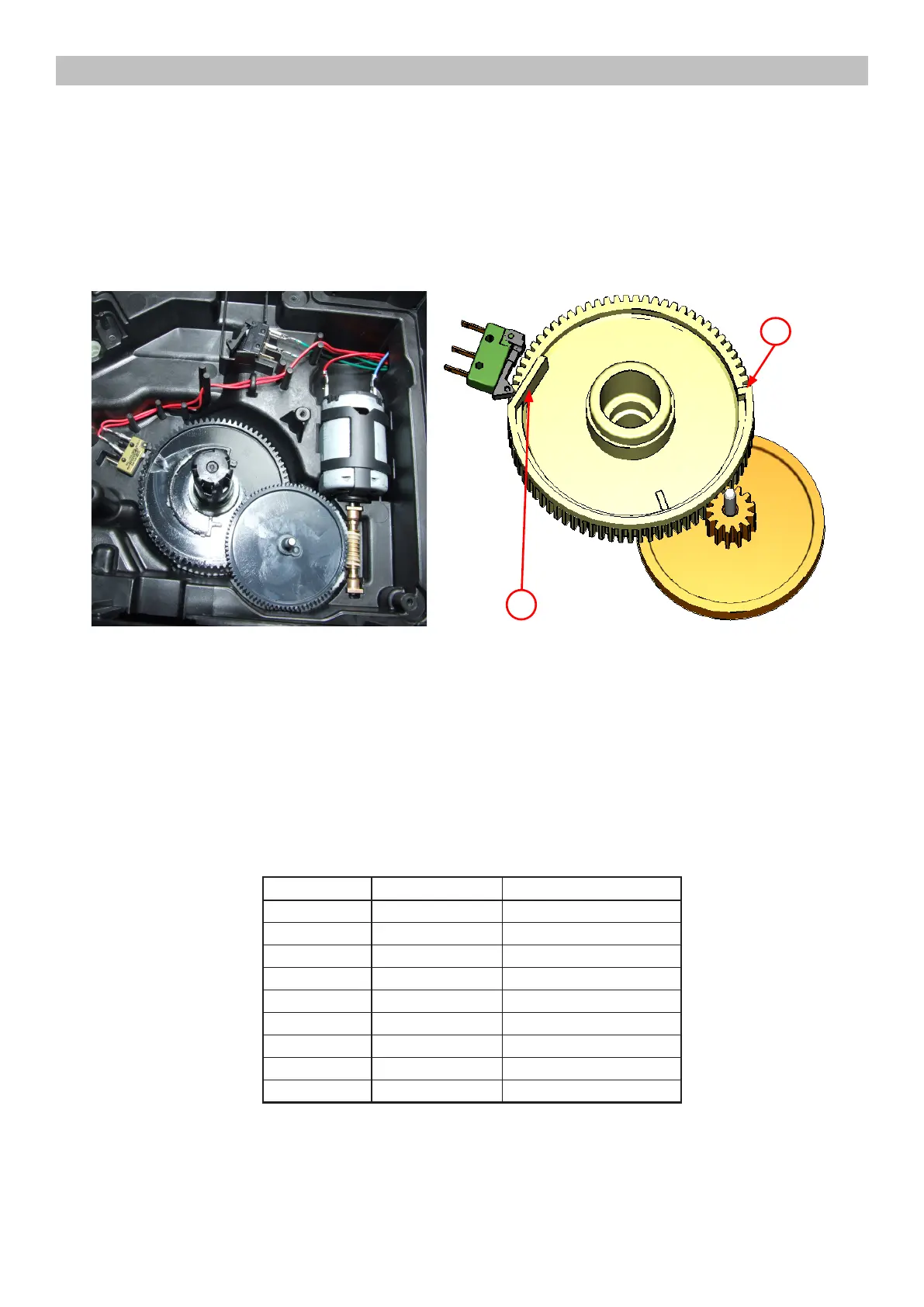

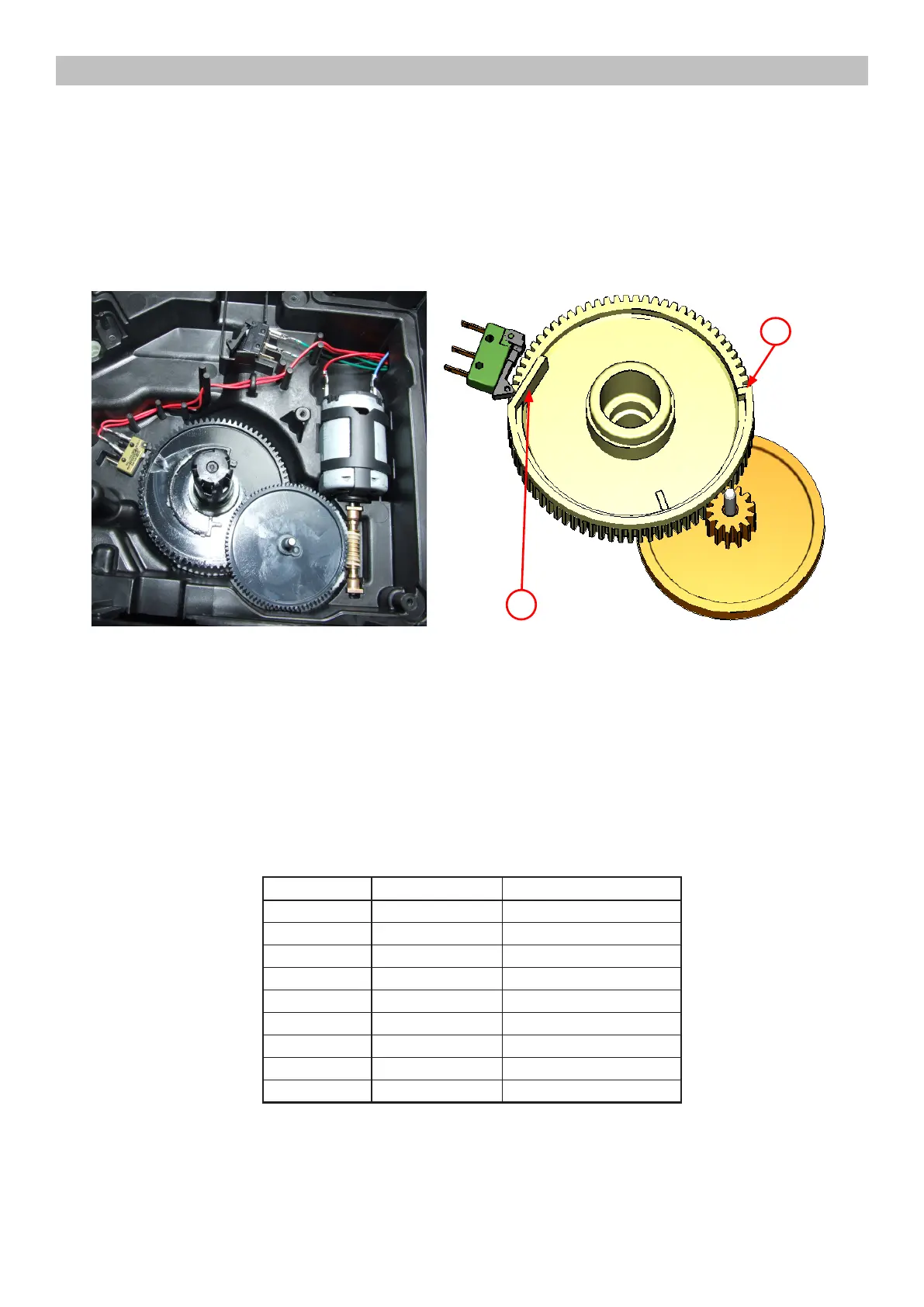

3.1. Single microswitch gear motor

e gear motor is powered by a direct current motor that engages with the smaller double toothed wheel

using a worm screw. e unit is mounted on the axle of the large gear wheel and when a coee is requested,

it moves from the standby position to the dispensing position, and then back to the standby position again.

e microswitch indicates to the gear motor when the brew group is in the work position or home position.

- Standby position: 1

- Dispensing position: 2

2

1

Loading...

Loading...