Circuit Descriptions, List of Abbreviations, and IC Data Sheets

EN 86 L04L AA9.

During the first half of the intensity increase, the scan velocity

is increased (thus decreasing the current density by spreading

it on a wider area). During the second half of the intensity

increase, the scan velocity is decreased (increasing the current

density by concentrating it on a smaller area). The increasing

current density transition is sharpened. A decreasing current

density transition is processed in a similar way and is also

sharpened.

In this chassis the SCAVEM signal is different from its

predecessor because the Hercules generates the differential

SCAVEM signal inside the IC.

The supply of the SCAVEM is taken from V_bat through a 1k5

/ 5 W resistor. Compared with the L01.1, this has the advantage

of getting better performance for the pattern with tremendous

SCAVEM current (like V_sweep). In this former chassis,

because the supply was taken from the 200 V through a 8k2 /

5 W resistor, the supply dropped significantly during a large

SCAVEM current. In this chassis, the drop due to the pattern

will be less because of the lower supply voltage impedance.

In the Main Board, 1st stage amplification is taken care by 7208

with the pull up resistors (3361, 3387) located in the CRT panel.

TS7361 and TS7362 is the current buffer delivering the current

to the output stage. The diode D6361 is to lightly bias these

transistors, to get rid of the zero crossover of the stage.

After that, the signal is ac-coupled to TS7363 and TS7364

where the emitter resistors (R3364 and R3370) will determine

the final SCAVEM current. TS7363 and TS7364 are biased by

R3363, R3366, R3367 and R3368.

C2387, R3388, R3389, R3365, R3369, C2384, and C2385 are

used for suppressing unwanted oscillations.

The function of TS7376 is to limit the SCAVEM current from

going too high. It basically senses the voltage after R3373 and

clamps the SCAVEM signal through D6367 and C2376.

9.4 Control

The Micro Controller is integrated with the Video Processor,

and is called the Hercules. For dynamic data storage, such as

SMART PICTURE and SMART SOUND settings, an external

NVM IC is being used.

Another feature includes an optional Teletext/Closed Caption

decoder with the possibility of different page storage depending

on the Hercules type number.

The Micro Controller ranges in ROM from 128 kB with no TXT-

decoder to 128 kB with a 10 page Teletext or with Closed

Caption.

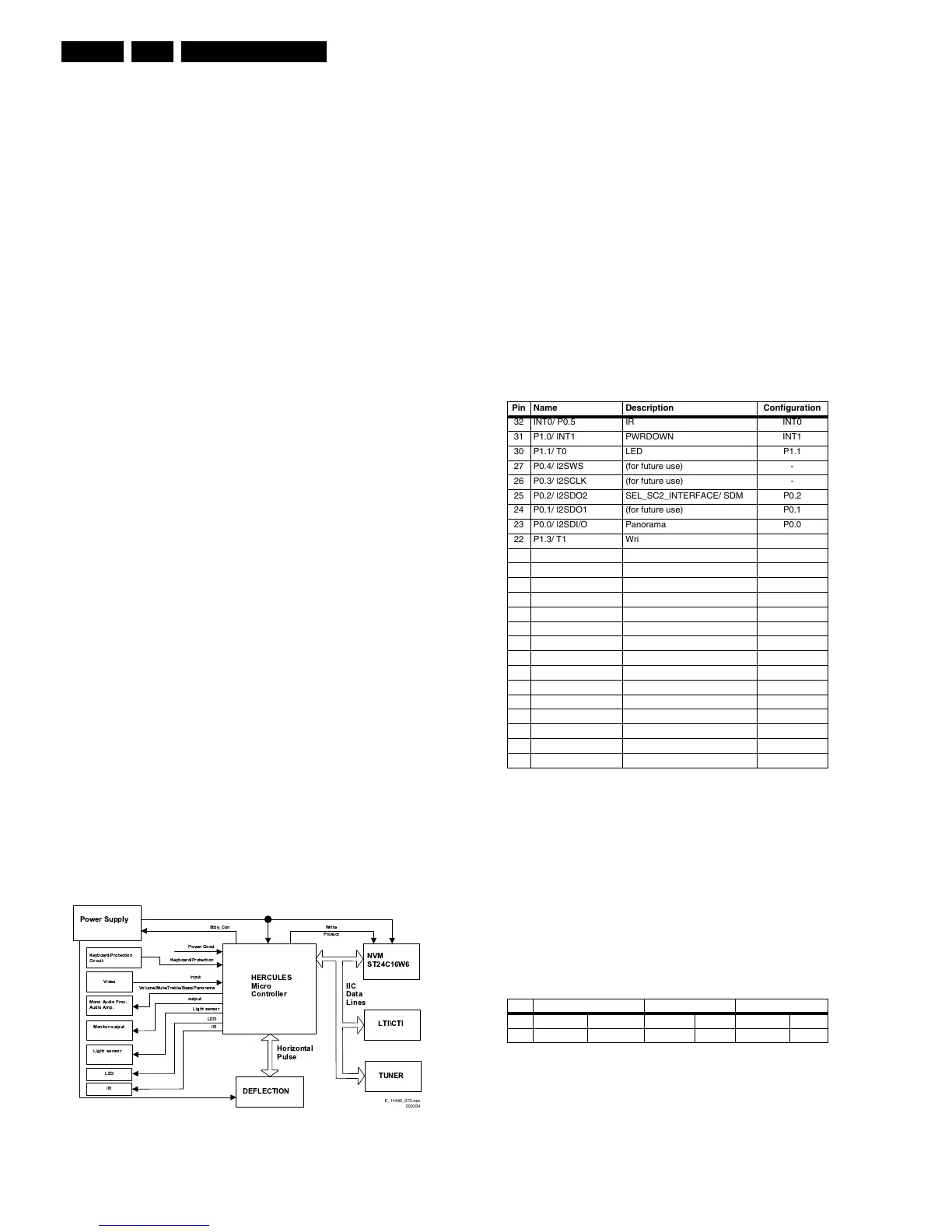

9.4.1 Block Diagram

The block diagram of the Micro Controller application is shown

below.

Figure 9-4 Micro Controller block diagram

9.4.2 Basic Specification

The Micro Controller operates at the following supply voltages:

• +3.3 V_dc at pins 33, 125, and 19.

• +1.8 V_dc at pins 126, 36, and 33.

• I2C pull up supply: +3.3V_dc.

9.4.3 Pin Configuration and Functionality

The ports of the Micro Controller can be configured as follows:

• A normal input port.

• An input ADC port.

• An output Open Drain port.

• An output Push-Pull port.

• An output PWM port.

• Input/Output Port

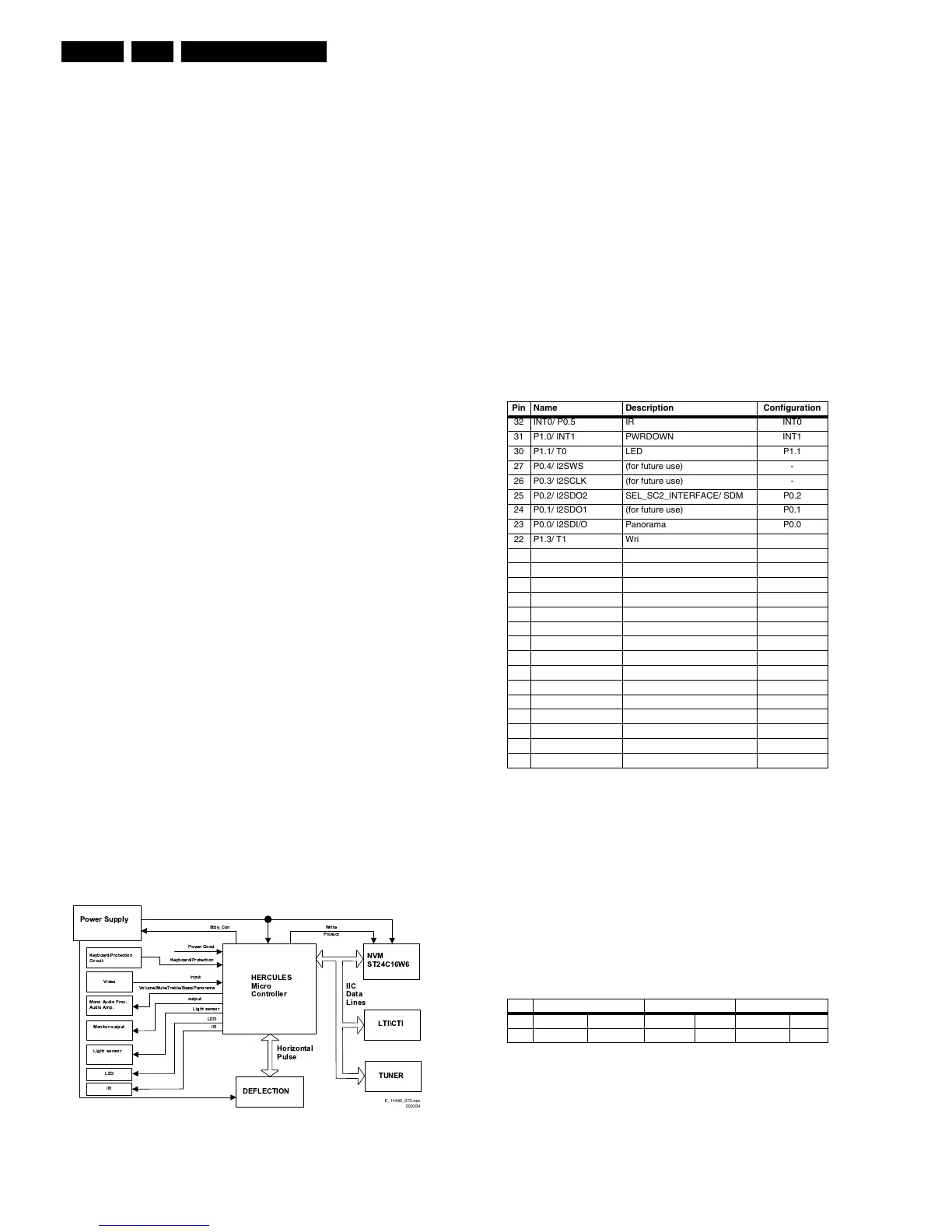

The following table shows the ports used for the L04 control:

Table 9-4 Micro Controller ports overview

The description of each functional pin is explained below:

• LED. This signal is used as an indication for the Standby,

Remote and Error Indicator. Region diversity:

– During protection mode, the LED blinks and the set is

in standby mode.

– During error conditions it blinks at a predefined rate.

– After receiving a valid RC-5 or local keyboard

command it flashes once.

– For sets with error message indication, the LED blinks

when message is active and the set is in standby

mode.

Table 9-5 LED signal diversity

• SCL. This is the clock wire of the two-wire single master bi-

directional I2C bus.

• SDA. This is the data wire of the two-wire single master bi-

directional I2C bus.

• STDBY_CON. The Hercules generates this signal. This

can enable the MAIN SMPS in normal operation and

disable it during Standby. It is of logic “low” (0 V) under

normal operation and “high” (3.3 V) during Standby.

!

"

# !$$%

&%'

# ()

*%&)+

)

$!

!

*%&)+

E_14480_070.eps

200204

Pin Name Description Configuration

32 INT0/ P0.5 IR INT0

31 P1.0/ INT1 PWRDOWN INT1

30 P1.1/ T0 LED P1.1

27 P0.4/ I2SWS (for future use) -

26 P0.3/ I2SCLK (for future use) -

25 P0.2/ I2SDO2 SEL_SC2_INTERFACE/ SDM P0.2

24 P0.1/ I2SDO1 (for future use) P0.1

23 P0.0/ I2SDI/O Panorama P0.0

22 P1.3/ T1 Write Protect P1.3

21 P1.6/ SCL SCL SCL

20 P1.7/ SDA SDA SDA

18 P2.0/ TPWM VOL_MUTE P2.0

17 P2.1/ PWM0 ROTATION PWM0

16 P2.2/ PWM1 SEL_LL'/M P2.2

15 P2.3/ PWM2 STANDBY_CON P2.3

14 P3.0/ ADC0 Light Sensor ADC0

13 P3.1/ ADC1 (for future use) -

10 P3.2/ ADC2 (for future use) -

9 P3.3/ ADC3 KEYBOARD ADC3

7 P2.4/ PWM3 A (for future use) P2.4

6 P2.5/ PWM4 B (for future use) P2.5

3 P1.2/ INT2 C (for future use) INT2

2 P1.4/ RX E (for future use) -

1 P1.5/ TX D (for future use) -

LED Europe AP/ LATAM NAFTA

0 LED brighter Standby LED lighted Standby LED lighted Normal

1 LED dimmer Normal LED "off" Normal LED "off" Standby

Loading...

Loading...