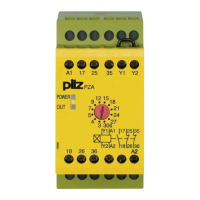

PZA

Operating Manual PZA

18219-EN-07

9

} t

v

: Delay time

[1]: Normal operating cycle

[2]: Fault: Input circuit opened too early

[3]: Fault: Feedback loop closed too late after t

v

elapsed

NOTICE

At the earliest the safety contacts close after the set delay time - 15% of the

set value, even in the case of a component failure.

Installation

} The unit should be installed in a control cabinet with a protection type of at least IP54.

} Use the notch on the rear of the unit to attach it to a DIN rail (35 mm).

} When installed vertically: Secure the unit by using a fixing element (e.g. retaining

bracket or end angle).

Wiring

Please note:

} Information given in the "Technical details" must be followed.

} The output 17-18 is a safety contact, outputs 25-26, 35-36 are auxiliary contacts (e.g.

for display).

} Do not use auxiliary contacts 25-26, 35-36 for safety circuits!

} To prevent contact welding, a fuse should be connected before the output contacts (see

Technical details).

} Do not connect undesignated terminals.

} Calculation of the max. cable length l

max

in the input circuit:

R

lmax

= max. overall cable resistance (see Technical details)

R

l

/km = cable resistance/km

} Use copper wire that can withstand 60/75°C.

} Sufficient fuse protection must be provided on all output contacts with capacitive and in-

ductive loads.

} Do not switch low currents using contacts that have been used previously with high cur-

rents.

} Ensure the wiring and EMC requirements of EN 60204-1 are met.

} On 24 VDC devices:

The power supply must comply with the regulations for extra low voltages with protect-

ive electrical separation (SELV, PELV) in accordance with VDE 0100, Part 410.

} In devices for 24 V DC shorts between the input circuit and feedback loop or earth

faults in the feedback loop can damage the unit. We recommend the use of a short cir-

cuit-proof supply voltage with current limitation.

Loading...

Loading...