Title

Doc no.

RD07-001

Date (ISO 8601)

Best Practice

BM 2000 Systems

2007-07-05

Process owner Author Sign. Quality Section Revision Page

R&D Dept + Tech Support BOL 1 4(13)

K:\Produkte\PL88 RoHS\BM 2000 Best Practice doc

Message “Cover Open” won’t go away

First generation machines have Interlock Switch PCBs

where the magnet sometimes is badly attached. New

PCBs have a new magnet holder that won’t fall off and

also positions the magnet at the right spot.

A second cause could be that the dome cap on the

switch has fallen off, due to excessive force from the

interlock cheater.

Remedy: In both cases, replace PCB, P/N 771134

New magnet holder

Q2 Manual Feed Sensor Problems

We have one reported case where sensor Q2 was

activated by the sheet metal, i.e. the cut-out wasn’t big

enough for that particular sensor. The root cause was

a bad sensor. It was, though, possible to use the faulty

sensor by adjusting it slightly sideways. A normal

sensor has a very large margin.

Symptom: This can lead to a number of different

errors. Normally if there is a signal from the sensor the

machine switches to manual feed mode. When a

sheet enters from the Collator it will lead to a jam

situation.

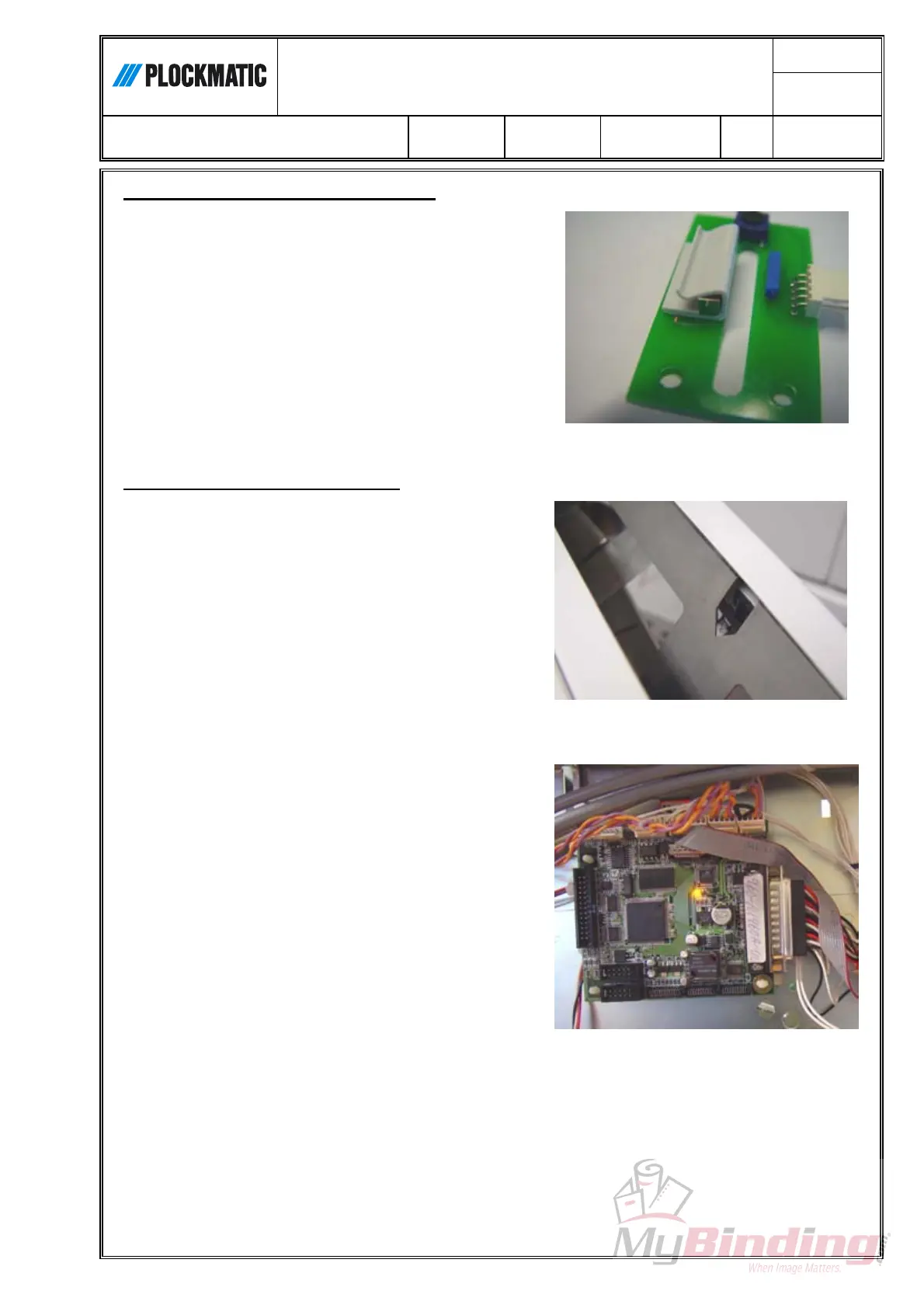

Verification of problem:

1. Remove the front cover so that you can see

the control PCB.

2. Watch the blinking yellow LED on the PCB

shown in picture 1 and 2. The LED makes an

extra blink whenever a sensor is activated or

deactivated. Normally the LED should blink

regularly once per second. If the LED flickers it

indicates a sensor is generating too many

impulses or there is a bad connection between

sensor and PCB.

Loading...

Loading...