△

1211

CT1

C

B

A

c

b

10 9 8

7

6 5

4

3

2

19

20

21

CT2

a

31302928

27

2625

24

23

22

FG

1

A

B

RS-485

C1

、

ub ua

uc

13

14

15

16

17

18

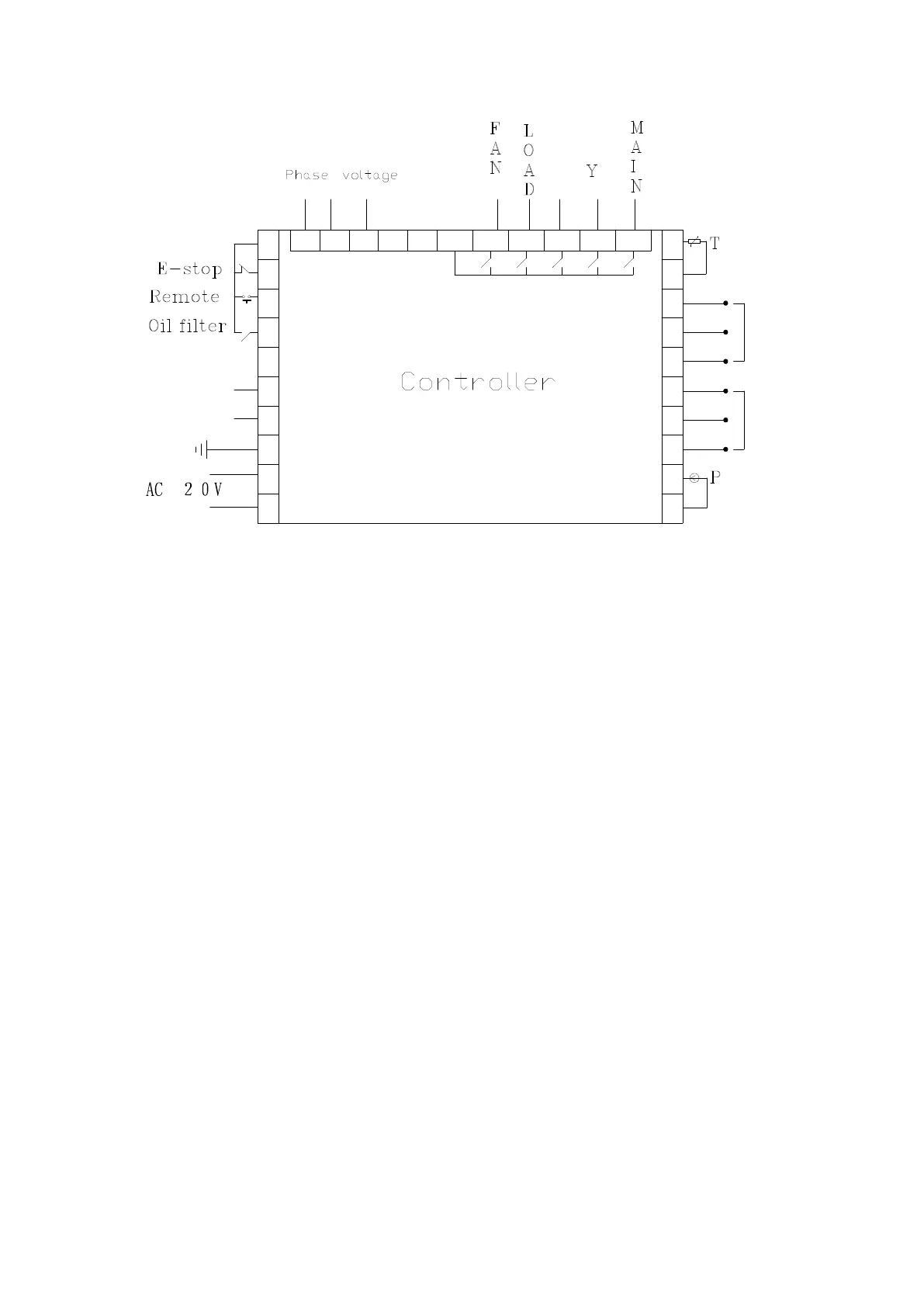

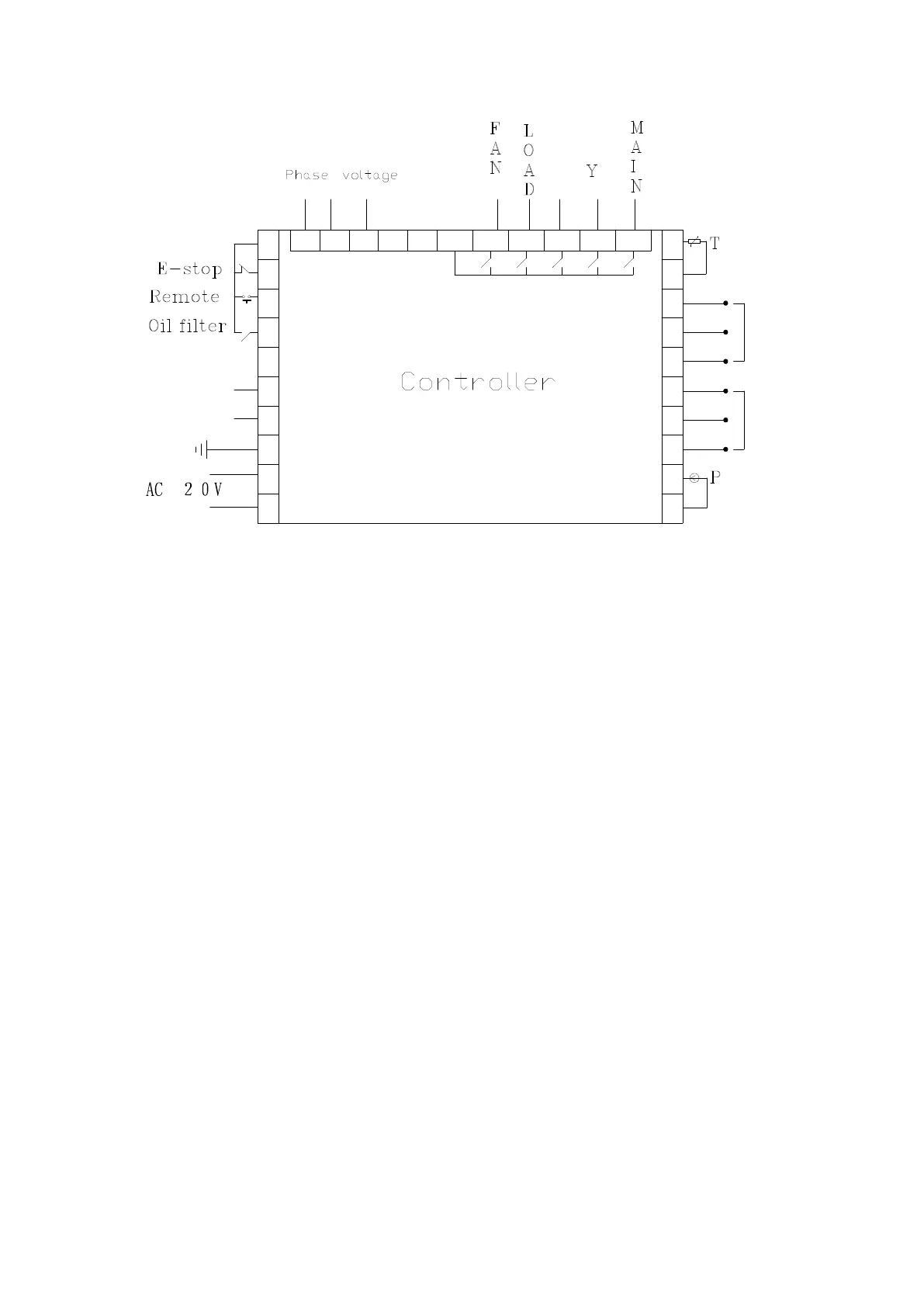

Figure 4.2.1 Terminal arrangement diagram

Terminal blocks of controller:

1 is common terminal COM1;2 is input terminal for emergent stop signal; 3 is remotely controlled for

on/off signal input terminal;4 terminal is used to detect oil filter blocked; 6 is RS485 A; 7 is RS485 B;8 is the

simulated ground (Earth);17 and 18 are the AC20V power source;22、23 terminals are Pressure Sensor signal

input;24、25、26 terminals are motor mutual inductor CT1 input;27、28、2 terminals are Fan mutual inductor

CT2 input;30、31 terminals are Temperature Sensor signal input;19、20、21 terminals Used to detect the phase

sequence and voltage;13 terminals is common terminal of output relay;14 terminals controls fan;15 terminals

controls load valve;16 terminals controls angle-shaped contactor;17 terminals controls star-shaped contactor;

18 terminals controls main contactor。

NOTE: Eelectromagnetism coil shall be connected with surge absorber during wiring, and

dotted lines are extendable functions.

5、 Control principles

1、Local Automatic control

①. press down start button for starting: (Y-△start)

There is fives of self-test after controller is energized and it can not be started by pressing start

button .The air compressor starts by pressing start button after self-test finished. The course of

compressor’s start as followed: KM3 and KM2 are energized → Y-type status of start → delay time is

reached (Y-△change-over time); KM3 is de-energized (KM1 and KM3 are interlocked) and KM1 is

energized → motor operates with △ type to finish start. During the course of starting, all

electromagnetism valves are de-energized to achieve no load start.

②. Automatic operation control:

When the motor is started to running in △ status and load the magnetic valve with

Loading...

Loading...