19

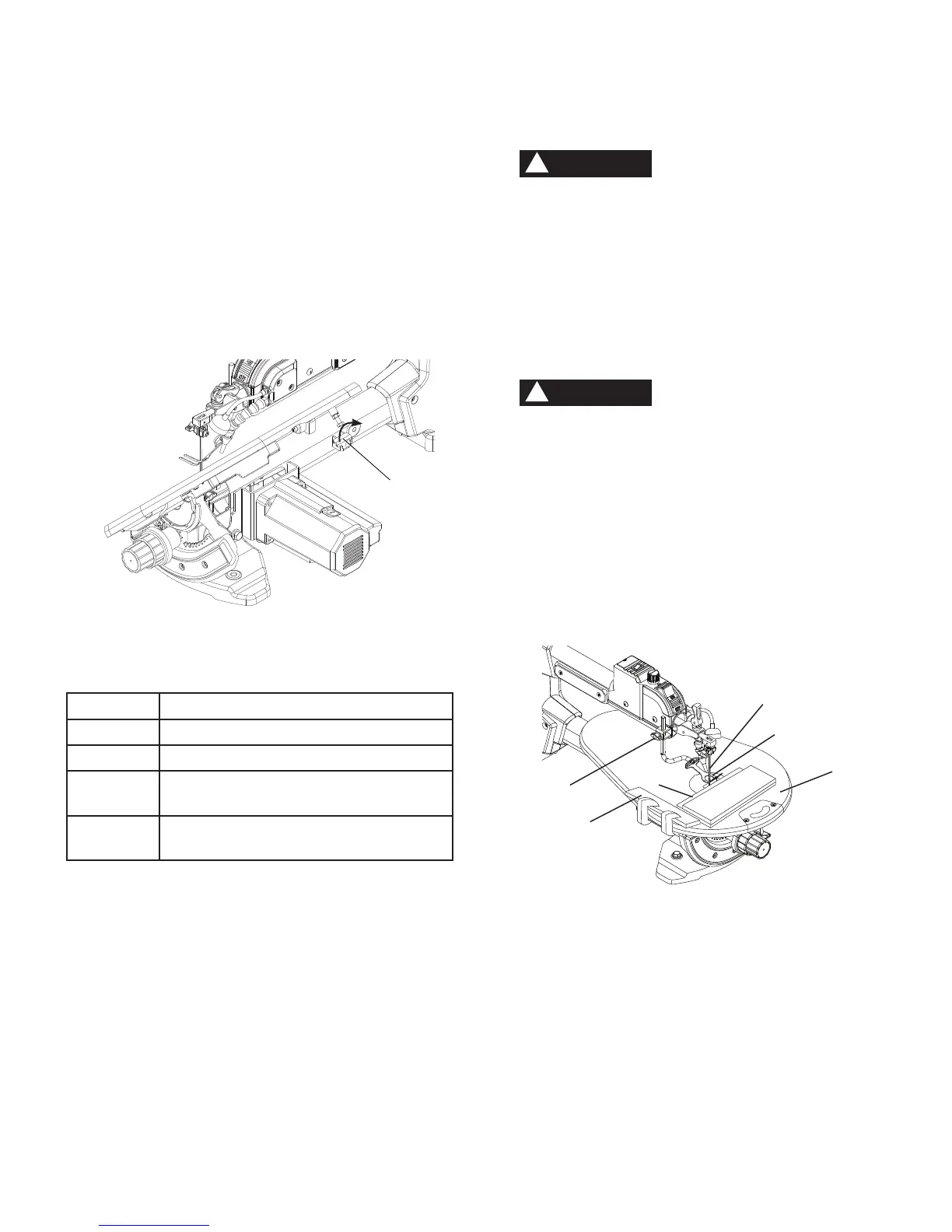

Right Bevel Cutting (maximum 15 degrees)

1. Lay out or secure design to workpiece (1).

2. Move the blade guard foot (2) to the highest position

by loosening the blade guard foot lock knob (3) and

retighten.

3. Tilt the table (5) to the left by loosening the table lock

knob (6), and lifting the anchor plate (11) to the rear

of the saw. Tilt the table to the right, it will stop at the

angle of 15°.

4. Tighten the table lock knob (6).

5. Follow steps 5-7 under Left Bevel Cutting.

Fig. S

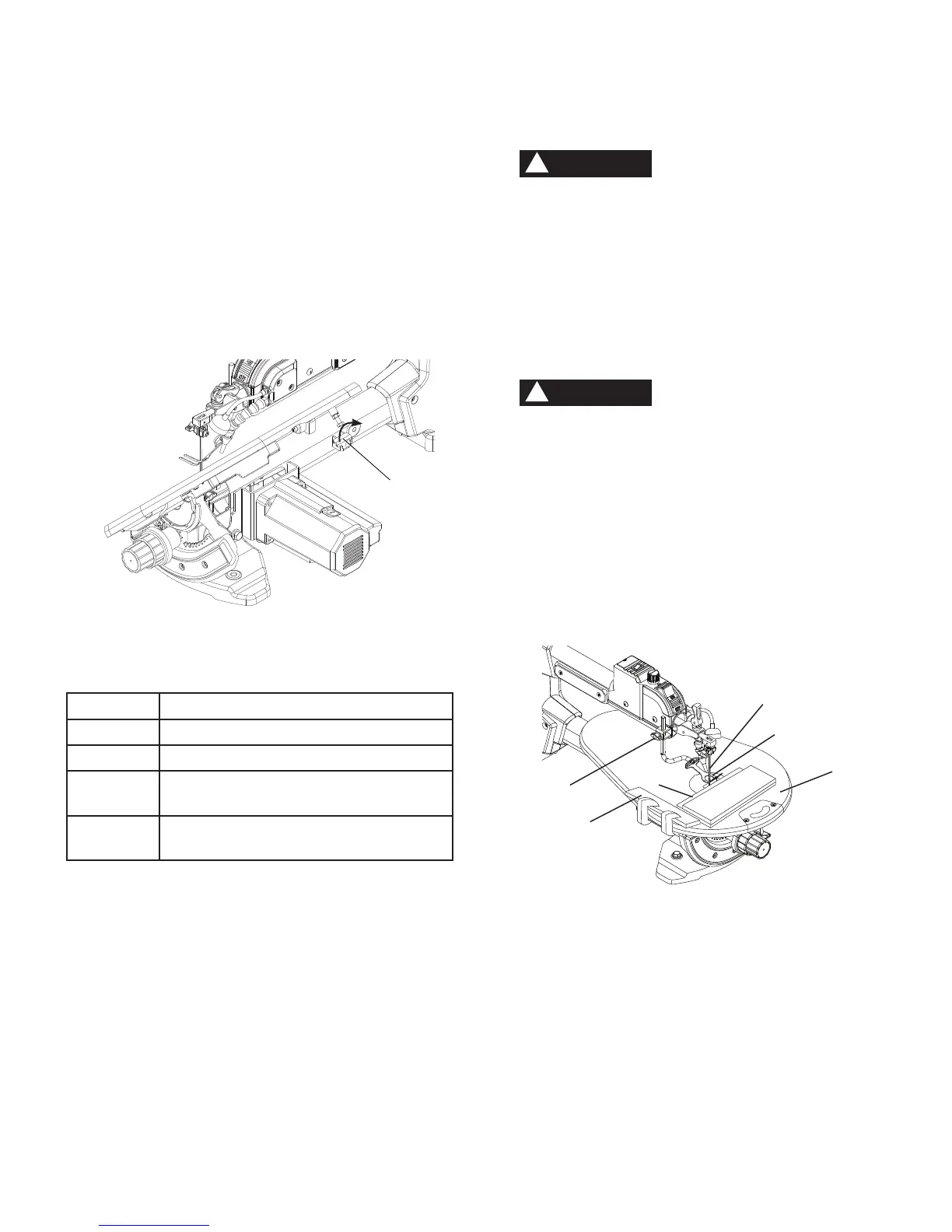

RIP OR STRAIGHT LINE CUTTING (FIG. T)

Tools Needed (Not Included)

1. Raise the blade guard foot (1) by loosening the

blade guard foot lock knob (2) on the left side of the

upper arm. Measure from the tip of the blade (3) to

the desired distance. Position the straight edge (4)

parallel to the blade at that distance.

2. Clamp the straight edge (4) to the table (5).

3. Recheck your measurements, using the workpiece to

be cut, and make sure the scrap wood (6) is secure.

4. Position the workpiece against the blade and place

the blade guard foot (1) slightly above the top surface

of the workpiece.

5. Secure the blade guard foot in place by tightening

the blade guard foot lock knob.

QUANTITY DESCRIPTION

2 Small C-clamps

1 Ruler or measuring tape

1

12-inch (304.8 mm) -straight scrap of

wood (Thickness to match workpiece)

1 A piece of wood, metal, plastic etc. with

a straight edge

CAUTION

!

11

6. Remove the workpiece from the blade before

turning the scroll saw ON. Set the desired speed

by turning the speed control knob clockwise or

counterclockwise.

In order to avoid uncontrollable lifting of the

workpiece and reduce blade breakage, do not turn

saw ON while the workpiece is against the blade.

7. Position the workpiece against the straight edge (4)

prior to touching the leading edge of the workpiece

against the blade (3).

8. Slowly feed the workpiece into the blade, guiding the

workpiece against the straight edge and press the

workpiece down against the table while cutting.

Do not force the leading edge of the workpiece into

the blade. The blade will deect, reducing accuracy

of cut and may break.

9. When the cut is complete, move the trailing edge of

the workpiece beyond the blade guard foot. Turn the

scroll saw OFF.

NOTE: Use push stick when cutting a narrow

workpiece.

Fig. T

CAUTION

!

5

4

6

3

2

1

Loading...

Loading...