5

ENGLISH

Adjustments and Usage Prep

Air Supply and Connections

WARNING: Do not use oxygen, combustible gases,

or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

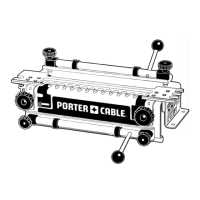

Fittings (Fig. B)

Install a male fitting

4

on the tool which is free flowing

and which will release air pressure from the tool when

disconnected from the supply source.

Fitting Torque Specification

Torque Specification for air fitting: 60-65 in-lbs

(69-75cm-kgf).

TOOL SPECIFICATIONS

Model TS056

Length 8.67" (220 mm)

Height 6.99" (178 mm)

Width 1.81" (46 mm)

Weight 2.3 lb (1.1 kg)

SUGGESTED FASTENER

SPECIFICATIONS

Model TS056

Fastener Series Porter Cable PC700 Staples Porter Cable® PBN Brads

Fastener Range 1/4"–9/16"

(6 mm–14 mm)

12 mm–15mm

(1/2"–5/8")

Fastener Type 3/8" Crown Staple 18 Gauge Brad Nail

Tool Air Fitting (Fig. B)

This tool uses a free flow connecting plug 1/4" N.P.T.

4

The inside diameter should be .200" (5mm) or larger. The

fitting must be capable of discharging tool air pressure when

disconnected from the air supply

7

.

Operating Pressure

80 to 100p.s.i.g. (5.5 to 6.9kg/cm²). Select the operating

pressure within this range for best pin performance. DONOT

EXCEED THIS RECOMMENDED OPERATINGPRESSURE.

Air Consumption

Model CMPCS38 requires 0.41 cubic feet per min (c.f.m.) of

free air to operate at the rate of 100 fasteners per minute,

at 100 p.s.i.g. (6.9 bars). Take the actual rate at which the

tool will be run to determine the amount of air required. For

instance, if your fastener usage averages 50 fasteners per

minute, you need 50% of the tool’s c.f.m. of free air which is

required for running at 100 fasteners per minute.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove air supply before

making any adjustments or removing/installing

attachments or accessories. An accidental actuation

can causeinjury.

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz .......................hertz

min ..................... minutes

or DC ......direct current

...................... Class I Construction

(grounded)

…/min ..............per minute

BPM .................... beats per minute

IPM ..................... impacts per minute

RPM .................... revolutions per

minute

sfpm ................... surface feet per

minute

SPM .................... strokes per minute

A ......................... amperes

W ........................watts

or AC ...........alternating current

or AC/DC .... alternating or direct

current

...................... Class II Construction

(double insulated)

n

o

.......................no load speed

n .........................rated speed

......................earthing terminal

.....................safety alert symbol

.....................visible radiation

..................... wear respiratory

protection

..................... wear eye protection

..................... wear hearing

protection

..................... read all

documentation

WARNING:ALWAYS use safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or

dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETYEQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratoryprotection.

WARNING:

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicalsare:

• lead from lead‑based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from

chemically‑treatedlumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter

out microscopicparticles.

• Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of

harmfulchemicals. Direct particles away from face andbody.

• Use the appropriate dust extractor vacuum to remove

the vast majority of static and airborne dust. Failure

to remove static and airborne dust could contaminate the

working environment or pose an increased health risk to

the operator and those in closeproximity.

• Use clamps or other practical ways to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and may

lead to loss ofcontrol andinjury.

• Air vents often cover moving parts and should be

avoided. Loose clothes, jewelry or long hair can be caught

in movingparts.

Loading...

Loading...