ENGLISH

6

Air Supply-Pressure and Volume

Air volume is as important as air pressure.The air volume

supplied to the tool may be inadequate because of

undersize fittings and hoses, or from the effects of dirt and

water in the system.Restricted air flow will prevent the tool

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove air supply before

making any adjustments or removing/installing

attachments or accessories. An accidental actuation

can causeinjury.

Your PORTER-CABLE power tool has been designed to

operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends

upon proper tool care and regularcleaning.

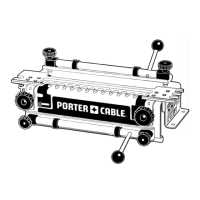

Tool Operation Check (Fig. A)

WARNING: remove all fasteners from tool before

performing tool operation check.

Trigger Operation with a Secondary

Trigger

WARNING: The trigger will only actuate the tool if the

secondary trigger has already been pulled.

The secondary trigger

3

is located under the handle

1

.

The secondary trigger prevents the primary trigger

2

from

actuating the tool if the secondary trigger has not been

pulled first.

Place the nose of the tool against a work piece for all of the

following operation checks.

1. With hand on rear end of the handle, further back away

from the secondary trigger, and not squeezing the

secondary trigger, use finger to pull the primary trigger.

THE TOOL MUST NOT CYCLE.

2. With hand on handle, and squeezing the secondary

trigger, use finger to pull the primary trigger. THE TOOL

MUST CYCLE.

While the secondary trigger remains squeezed, the tool will

cycle each time the primary trigger is pulled!

Trigger Operation With a Secondary

Trigger (Fig. A)

WARNING: Never inadvertently pull or grasp the

secondary trigger when moving about, changing work

location, when holstering or hanging tool, or when

preparing work surface for fastening operation.

WARNING: The operator must not hold the secondary

trigger pulled except during fastening operation as

serious injury could result if the trigger accidentally

contacts someone or something, causing the tool

tocycle.

When the secondary trigger

2

is pulled, the tool will actuate

each time the primary trigger

2

is pulled. This trigger

operated tool is operated by first pulling or grasping the

secondary trigger under the hand grip, followed by pulling

the trigger under the valve.

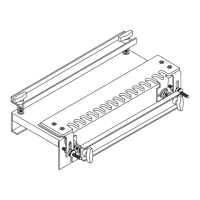

Loading (Fig. E–H)

WARNING: Be careful when handling fasteners,

especially when loading and unloading, as the

fasteners have sharp points.

1. Remove the air supply

7

from the 1/4" male fitting

4

.

2. Hold stapler upside down as shown and release loading

hatch

6

by pushing in the loading hatch release

button

5

.

3. Draw the loading hatch from the tool.

4. Place one stick of staples in bottom channel so legs are

pointing up. Push loading hatch closed, making sure the

loading hatch release button engages.

5. For brad nails, place only on left side (direction as shown

on the magazine liner). Be sure nail heads are pointing

down. Push loading hatch closed, making sure the

loading hatch release button engages.

Proper Hand Position (Fig. D)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the handle

1

.

After driving a fastener, this tool may spring back (“recoil”).

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove air supply before

making any adjustments or removing/installing

attachments or accessories. An accidental actuation

can causeinjury.

Hoses (Fig. B)

Air hoses should have a minimum of 150 p.s.i.g.(10.6kg/cm²)

working pressure rating or 150 percent of the maximum

pressure that could be produced in the air system. The supply

hose

7

should contain a fitting that will provide “quick

disconnecting” from the male fitting

4

on the tool.

Supply Source

Use only clean regulated compressed air as a power source

for this tool. NEVER USE OXYGEN, COMBUSTIBLE GASES, OR

BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOL AS

TOOL MAY EXPLODE.

Regulator

A pressure regulator with an operating pressure of

0–125p.s.i.g. (0–8.79 kg/cm²) is required to control the

operat iing pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially exceed

200 p.s.i.g. (14 kg/cm²) as tool may fracture or burst, possibly

causing injury.

Operating Pressure

Do not exceed recommended maximum operating pressure

as tool wear will be greatly increased. The air supply must be

capable of maintaining the operating pressure at the tool.

Pressure drops in the air supply can reduce the tool’s driving

power. Refer to Tool Specifications for setting the correct

operating pressure for the tool.

Loading...

Loading...