POWER ELECTRONICS

VS65 SERIES MV SOFT STARTER

WIRING ACCESS AND CONNECTION

31

6.4. Wiring recommendations

CAUTION

The installation must be done by qualified personal.

Otherwise, the equipment can be damaged and lead to injury to people.

The VS65 series soft starters are built-in an earth busbar. First of all, connect the input and output

shields, and the motor earth to the earth busbar of the soft starter (PE).

Connect the three input phases to the L1, L2 y L3 input terminals. Connect the three motor phases to the

U, V and W output terminals. These terminals are located on the back part of the soft starter, as it has

been described on the previous section.

The copper bars or the cables must satisfy the intensity capacity rule and the isolation voltage.

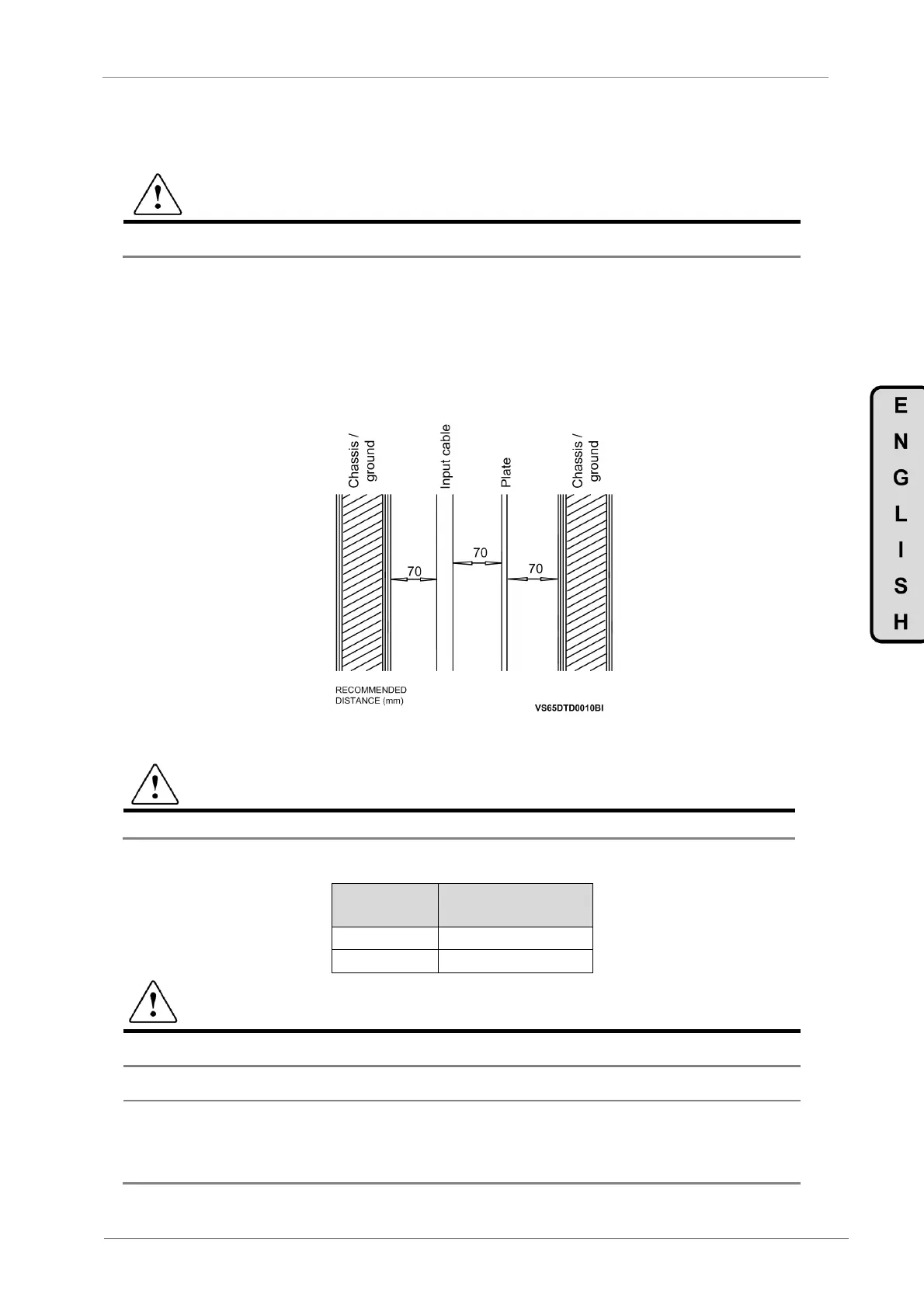

The cables installation must respect the minimum safety clearance between the plates and the

equipment as shown in the following figure.

Figure 6.10 Input cables safety distance

CAUTION

In any case the distance between plates and equipment should never be smaller than 60mm

Torque specifications for MV power connections in VS65 soft starter:

Bolt size

Torque at full

engagement (Nm)

M10 40

M12 60

CAUTION

ge (input supply) must never be connected to U, V and W terminals. Otherwise, the drive

will be damaged.

It is absolutely necessary that the installer guaranties the correct observance of the law and the

regulations that are in force in those countries or areas where this device is going to be installed.

For safety reasons it is determinant to

the grounding resistance of the plant itself.

This

must be established before the first start up of the plant and with the drive disconnected.

It is responsibility of the installer, to provide the adequate number, type and cross section

grounding conductor alongside with the characteristics of the drive used and of the Plant in order to

minimize the grounding resistance, that compliance with the local and national regulation.

Loading...

Loading...