10

It is essential that the mains water supply pressure and flow

availability are capable of meeting both the hot and cold water

services demand. The unit is capable of delivering up to 12

litres/min (140) or 18 litres/min (155x) of hot water. Where the

mains pressure is in excess of 6 bar, pressure reduction to

between 2 to 3 bar is recommended for splash free tap operation.

Unless consistently high mains pressures are available, it is

unlikely that a mains service pipe of less than 22mm OD

(copper) or 25mm OD (Blue MDPE) will provide an adequate

flow rate to the system. Powermax is not recommended for use

where the prevailing mains pressure is below 1.0 bar.

A full way isolating valve (e.g. gate valve or quarter-turn valve)

should be fitted in the supply before, but adjacent to, the unit.

It is recommended that a 22mm draw-off is provided from which

15mm or smaller pipes can then be used to supply hot water

services to individual terminations to give a balanced

distribution system.

Taps: Ensure that all terminal fittings will withstand mains

pressure.

Showers: Because of the draw-off profile, thermostatic shower

mixers are recommended to optimise performance; these must

be suitable for use at mains pressure. The Range ‘Showermax’

thermostatic shower kit is recommended for use with this boiler.

Where it is possible for a flexible shower handset to reach

below the bath spillover level, compliance with the Water

Byelaws is essential.

In areas where temporary hardness exceeds 200mg/L,

treatment of the mains water supplied to the appliance is

recommended to maintain its performance. The Powermax

electronic water conditioner P3237 is available factory fitted or

can be retro-fitted. Any scale reducer, or ion-exchange softener,

will be most effective when installed immediately upstream of

the boiler i.e. in the inlet pipework.

Good quality polyphosphate dosing devices can also inhibit

scaling but generally should not be fitted where heat could

impair their performance. Always follow the manufacturer’s

instructions.

Record the type of conditioner being used in log book.

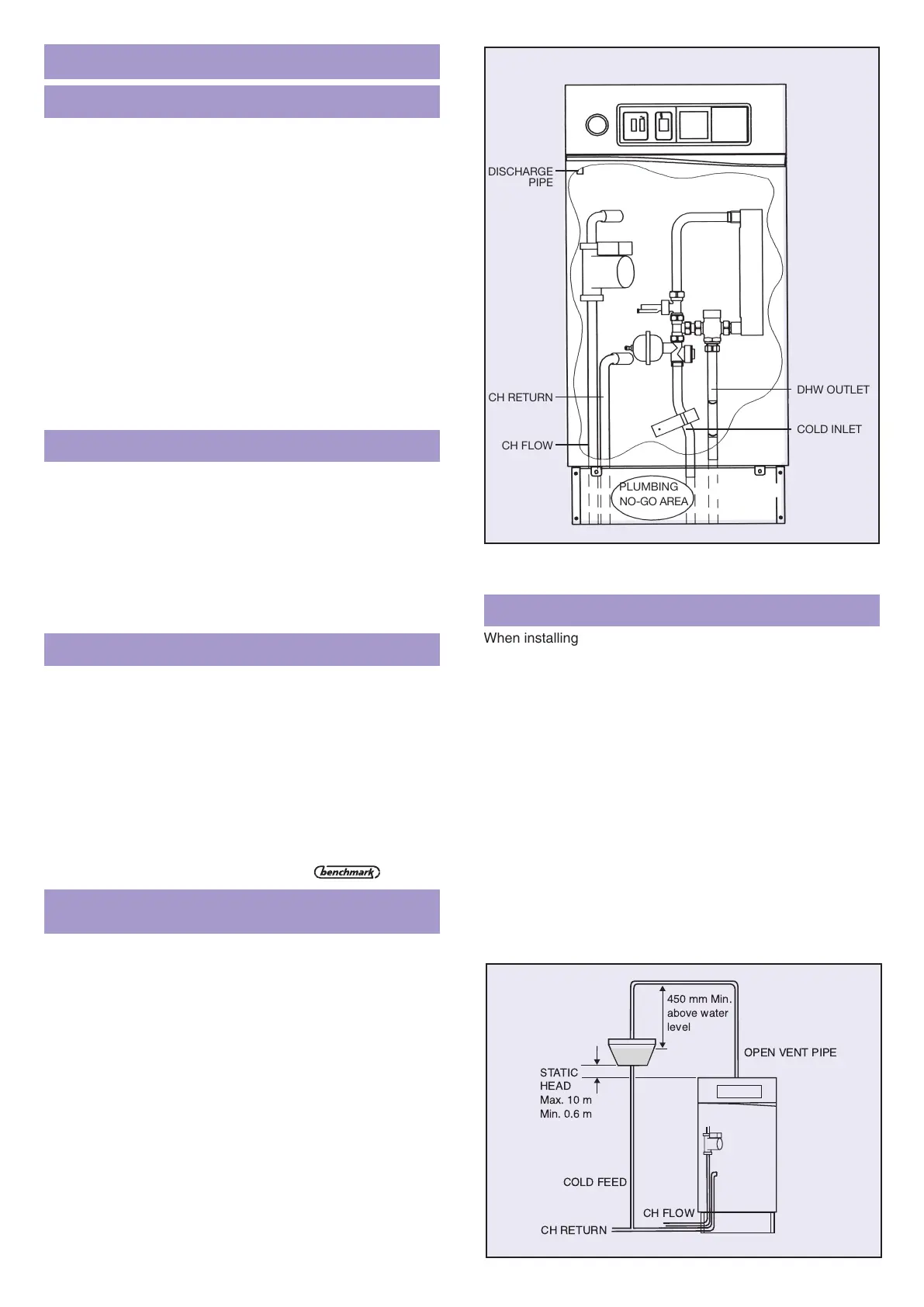

FLOW AND RETURN CONNECTIONS

These are on the LH side of the unit; the flow is taken from

below the pump. Pipework can be run inside the casing but

must not prevent the removal of the flue collector sump –

see NO GO area in Fig. 11.1. See also the plumbing layout

Guide on page 23.

PRIMARY SYSTEM

Use in Hard Water Areas

Terminal Water Fittings

Mains Supply Requirements

11 WATER SUPPLY

Fig. 11.1 Water connections

Fig. 11.2a

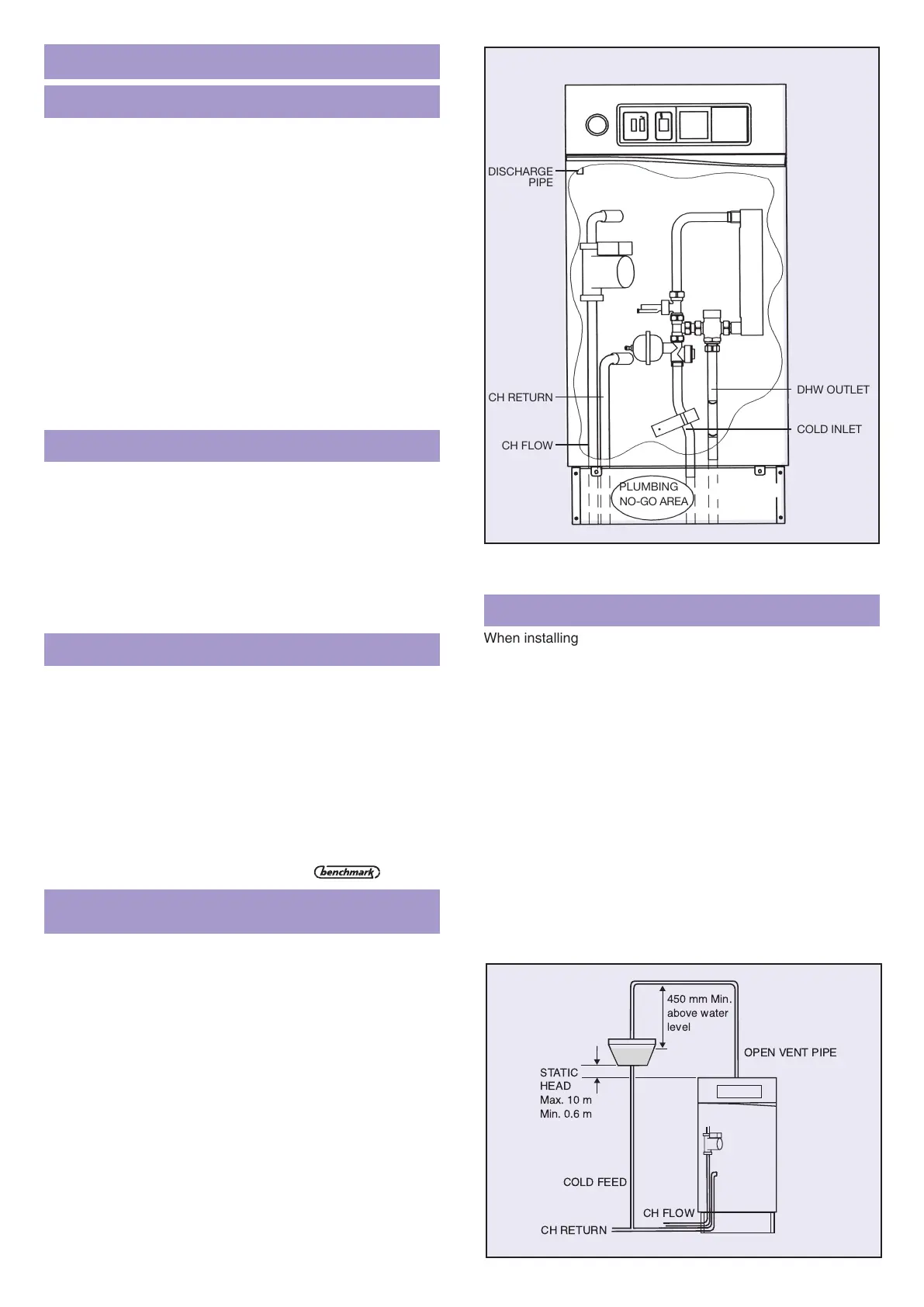

When installing ‘OV’ variants of Powermax the thermal store

within the appliance must be supplied with primary water from a

low pressure source e.g. a feed and expansion (F&E) cistern.

The unit is suitable for a maximum working head of 10 metres

(33ft head). The minimum static head is 600mm.

The vent pipe connection is situated at the top of the unit.

A 22mm open vent pipe must rise continuously, unimpeded, to

above the feed and expansion cistern. The top rear panel is cut

away to enable the vent pipe to run on the wall behind the

appliance.

Note also that the F & E water level must be at least 1metre

above the highest point of the primary circulation system.

An unvalved feed and expansion pipe must be provided from

the F & E cistern and teed into the C.H. return near the boiler.

Use 22mm if plastics pipe is used or if head is less than 1m.

Open Vented Systems

PIPEWORK ABOVE BOILER

Where the boiler has pipework rising above it, a non-return

valve should be fitted, preferably in the flow where it will not

obstruct filling.

Air vents must be fitted at the highest positions on flow and

return pipes and at any point where air is likely to collect.

TRVs IN SYSTEM

When all radiators are fitted with Thermostatic Radiator Valves,

a bypass loop (manual or automatic) must be provided.

SOLDER FLUX

Use water soluble flux for making soldered capillary joints in the

primary circuit. Traditional grease-based flux must not be used.

Loading...

Loading...