14

a With no water pressure on the system , check and if

necessary adjust expansion vessel pressure to 0.6 to 0.7

bar (8 to 10 psi) N.B. Vessel pressure cannot be

accurately set with water pressure in system.

b Loosen cap on automatic air vent, check draincock is

closed and open isolating valves on CH pump.

c Open stopvalve(s) and fill system with water to approx.

0.9 bar. Release air from radiators and pipework and run

cylinder up to temperature with CH off.

Bleed both heat exchanger and CH pumps.

d Thoroughly check radiator valve connections, glands

and unions for leaks.

e Set CH pump to speed 3, bleed every radiator and

pipework high points until all air or air/water mix is

removed.

f Allow system to reach full temperature (boiler ‘stat

switches off) and note HOT system pressure. Check that

relief valve is not “passing” by observing tundish over

several minutes.(“Passing” is usually due to debris on

valve seat. Snapping valve shut several times will

normally cure this). After firing and checking, drain and

flush the system, refill as above adding inhibitor, and

check for leaks.

g Again bleed every radiator etc. until all air or air/water

mix is removed and re check relief valve.

h Check system final pressure equals HOT pressure noted

in f above. Top up pressure if necessary.

i Adjust CH pump to correct speed for system. Remove

flexible hose and leave in a secure position for

householder. Protect hose union threads with end caps.

a Ensure Draincock is closed.

b Open valves either side of central heating pump .

c Admit water to the F&E cistern and thence to the

thermal store and the remainder of the central heating

system. Bleed both heat exchanger and CH pumps.

d Open any radiator valves and air bleed valves so as to

ensure that the store and radiators are full.

Note: Drain and flush the system. Refill as above adding

inhibitor, and check for leaks.

a Open one or more hot water taps.

b Turn on mains water supply and observe air free water

issuing from tap(s).

c Close tap(s) and check mains water pipework for leaks.

d Check that all factory-made plumbing connections

are tight (and have not loosened in transit).

e The blending valve is pre-set to supply water at

approximately 57°C and does not require adjustment.

CHECK POLARITY OF ELECTRICAL SUPPLY IS CORRECT.

CHECK THERMOSTAT WIRING, ie ‘SWITCHED’ WIRE IS

CONNECTED TO TERMINAL 28.

Remove screw from solenoid valve inlet pressure test point

Fig.13.4 and attach a suitable gauge.

a Turn any in-line gascock ‘on’ and turn the service

gascock ‘on’.(Indicated by the screwdriver slot being in

line with the direction of gas flow.) See Fig.12.3.

Starting (Lighting) The Appliance

Domestic Hot Water System

Open Vented Primary System

Sealed Primary System

12. COMMISSIONING

WARNING: DO NOT ATTEMPT TO START THIS APPLIANCE

UNLESS THE THERMAL STORE (PRIMARY CIRCUIT) HAS

BEEN FILLED WITH WATER

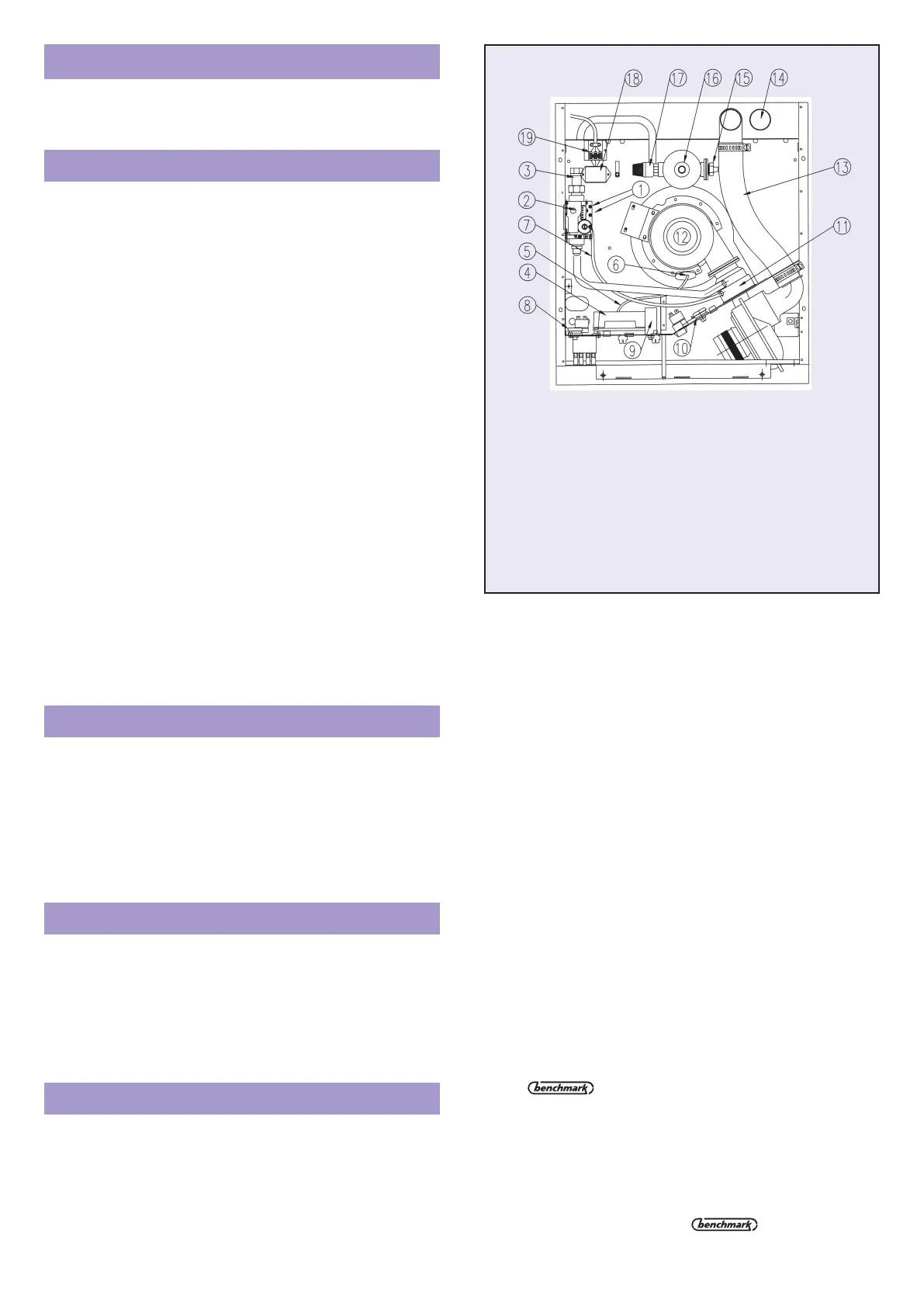

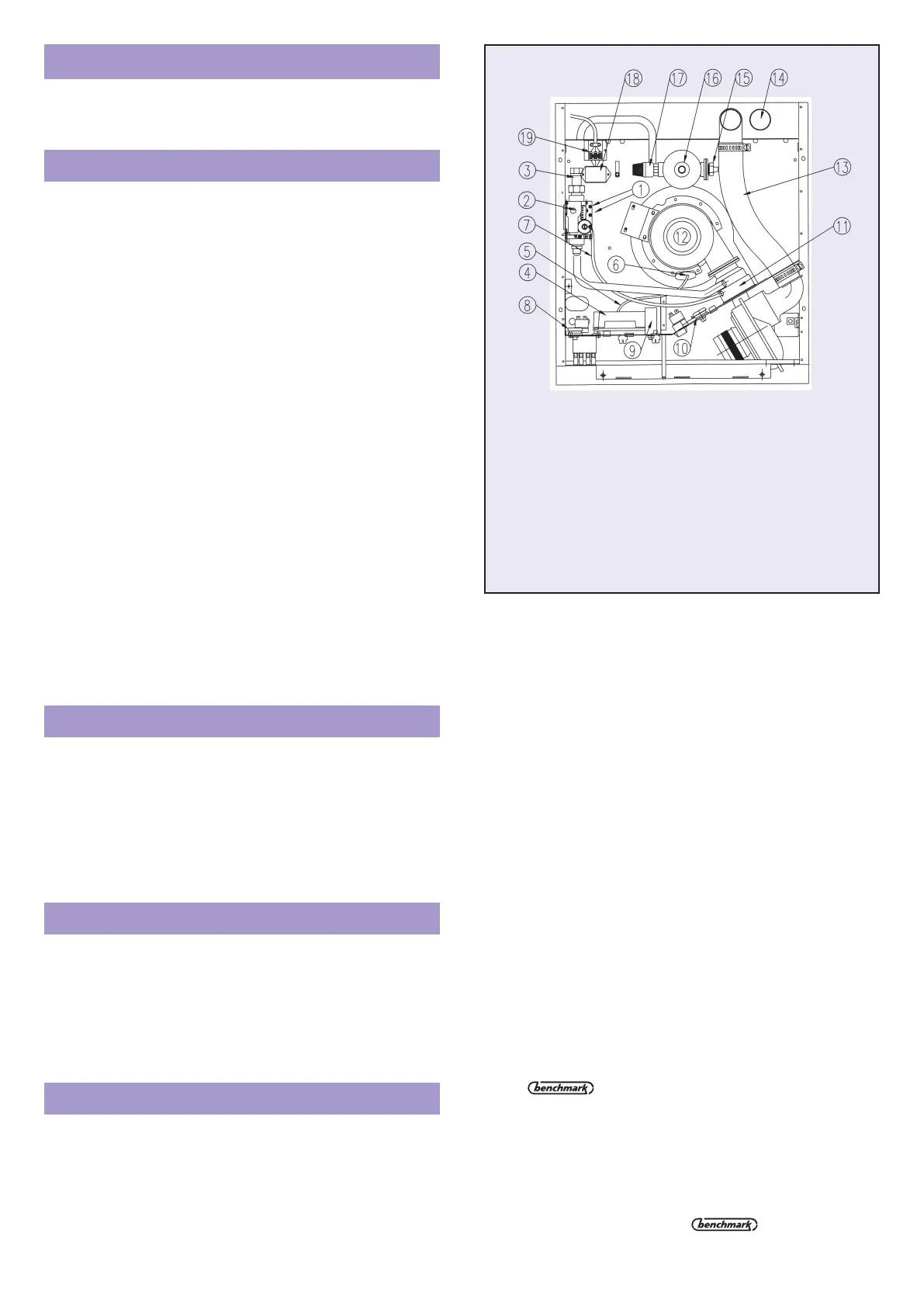

Fig. 12.1

1. Pressure Test Screws

2. Air-gas Ratio Valve

3. Union Gascock

4. Ignition Controller

5. H.T. Lead

6. Ignition Electrode

7. Air Sense Tube

8. Boiler Thermostat

9. Capacitor

10. Cold Start Thermostat

11. Injector

12. Burner

13. Air Inlet Pipe

14. Flue Pipe

15. Water Level Switch

16. Auto. Air Vent

17. Safety Relief Valve

18. EMC Filter

19. User Terminal

b Switch electricity supply on at the isolating switch and

observe orange neon on control panel indicating the

mains supply is live.

Note: Switch panel layouts are shown in Fig.12.4 for standard

model and Fig.12.5 for model with built-in programmer.

c Move the appliance on-off switch to the ‘I’ (on) position

(standard model) or ‘CONT’ (programmer model). Fan

starts to rotate after a slight delay. After a few seconds

the automatic ignition sequence will be initiated and the

burner will light.

d Green neon indicates the burner is operating.

Note: If the burner fails to light, the ignition sequence will be

automatically repeated until either the burner lights or a

safety LOCK-OUT condition is signalled by the red

neon. If red neon glows, switch to ‘O’ (OFF) at the

appliance on/off switch, WAIT TEN SECONDS

BEFORE SWITCHING ON AGAIN.

e With the appliance operating check the green neon is stable.

Note: After first filling with cold water some noise may

occur within the combustion chamber as the flame

settles on the burner. This is normal and will disappear

after approximately one minute. It does not occur in

normal use.

f Run boiler for 15-20 mins and transfer manometer tube

to outlet test nipple. Check burner pressure is

approximately 3.8 to 4.4 mbar (140) or 4.8 to 5.5 mbar

(155x). NB The longer the flue system the lower will be

the expected pressure. Record operating pressure in

log book. Very low values e.g. 3.0 mbar,

indicate an obstruction in the air supply; a high pressure

e.g. >6.0 mbar indicates a blockage in the flue pipe or

sump - see fault finder chart on page 12. Note that the

gas valve is factory pre-set and the burner pressure is

not directly adjustable. In case of difficulty consult The

Technical Helpline 0870 606 0955

g Record the “working” inlet gas pressure at inlet pressure

test nipple – Fig. 13.4 – in log book.

h Turn appliance off, remove gauge, replace test screws

and test for gas soundness.

Loading...

Loading...