MAX. No OF BENDS (90° or 135°) MAX. PIPE LENGTH

Air Inlet Flue Total Air/Flue inc. Terminal.

4 3 7 5.0m each

3 2 5 7.0m each

2 1 3 9.0m each

20

Installing Terminal Assembly

Note: The flue terminal must be installed horizontally.

a Mark the centre of the 140mm (5

1

/

2

inch) diameter hole

and core drill.

Note: If the wall is clad with a combustible material an

additional 25mm wide area must be removed around

liner.

Measure the wall thickness and cut the liner to this

length. Cut opposite end to lugs.

b Fit the liner through the 140mm diameter hole, lugs

inside, and make good internal and external rendering.

The latter may be done with arm extended through liner.

Note: Ensure lugs are either vertical or horizontal and

avoid filling threads in lugs with mortar.

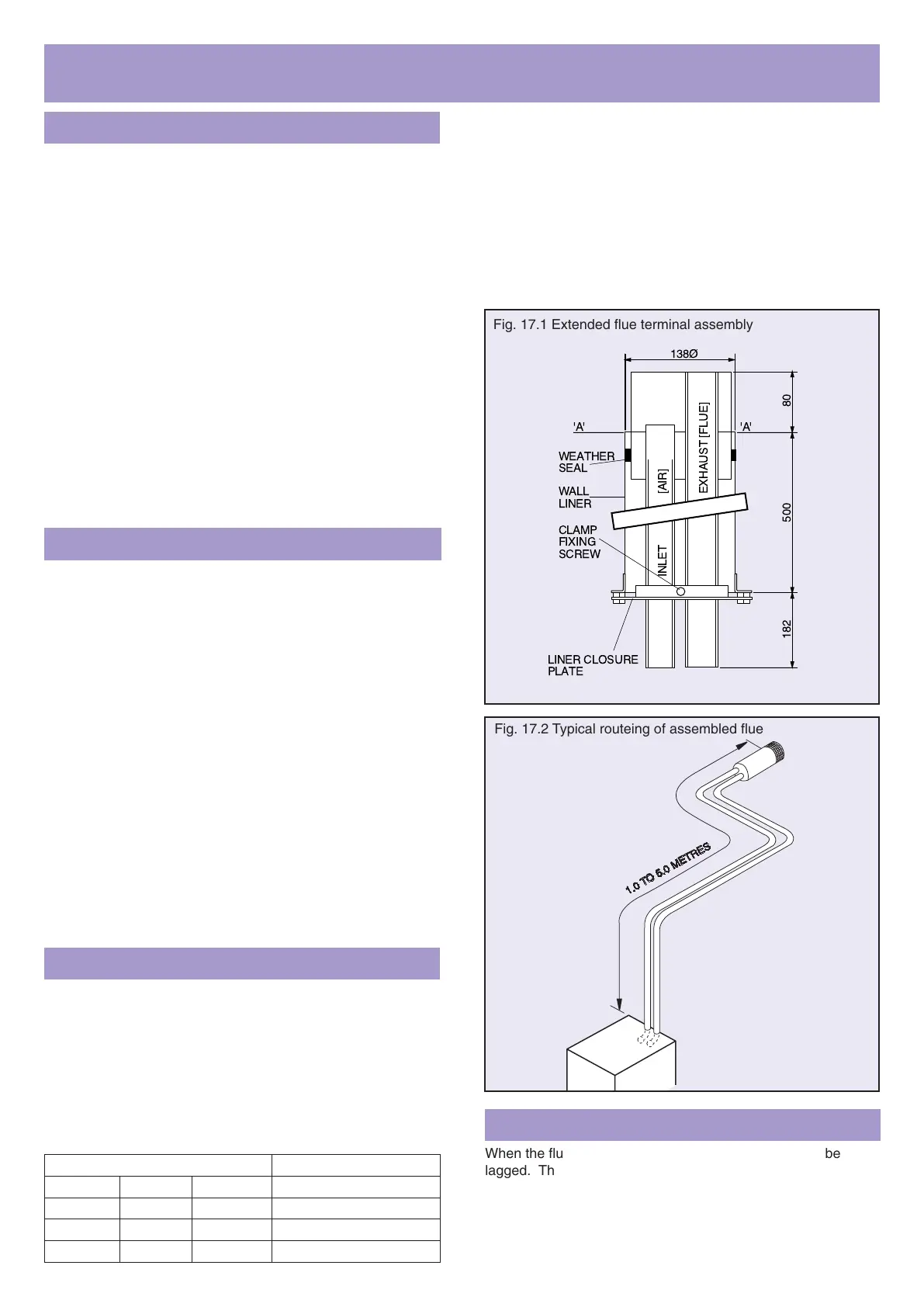

c Mark wall thickness measurement on terminal air/flue

pipes using datum ‘A’ ‘A’ shown in Fig. 17.1. Fix liner

closure plate on to the pipes at this length using the

clamp attached. Avoid crushing pipes with clamp. If

either pipe requires cutting to length (eg to allow bends

to be fitted) do this now.

d Push flue terminal assembly into liner. Secure terminal

by fixing plate to liner using the screws supplied.

17. INSTALLATION INSTRUCTIONS FOR EXTENDED BALANCED

FLUE SYSTEMS

Routeing of Air/Flue Pipes

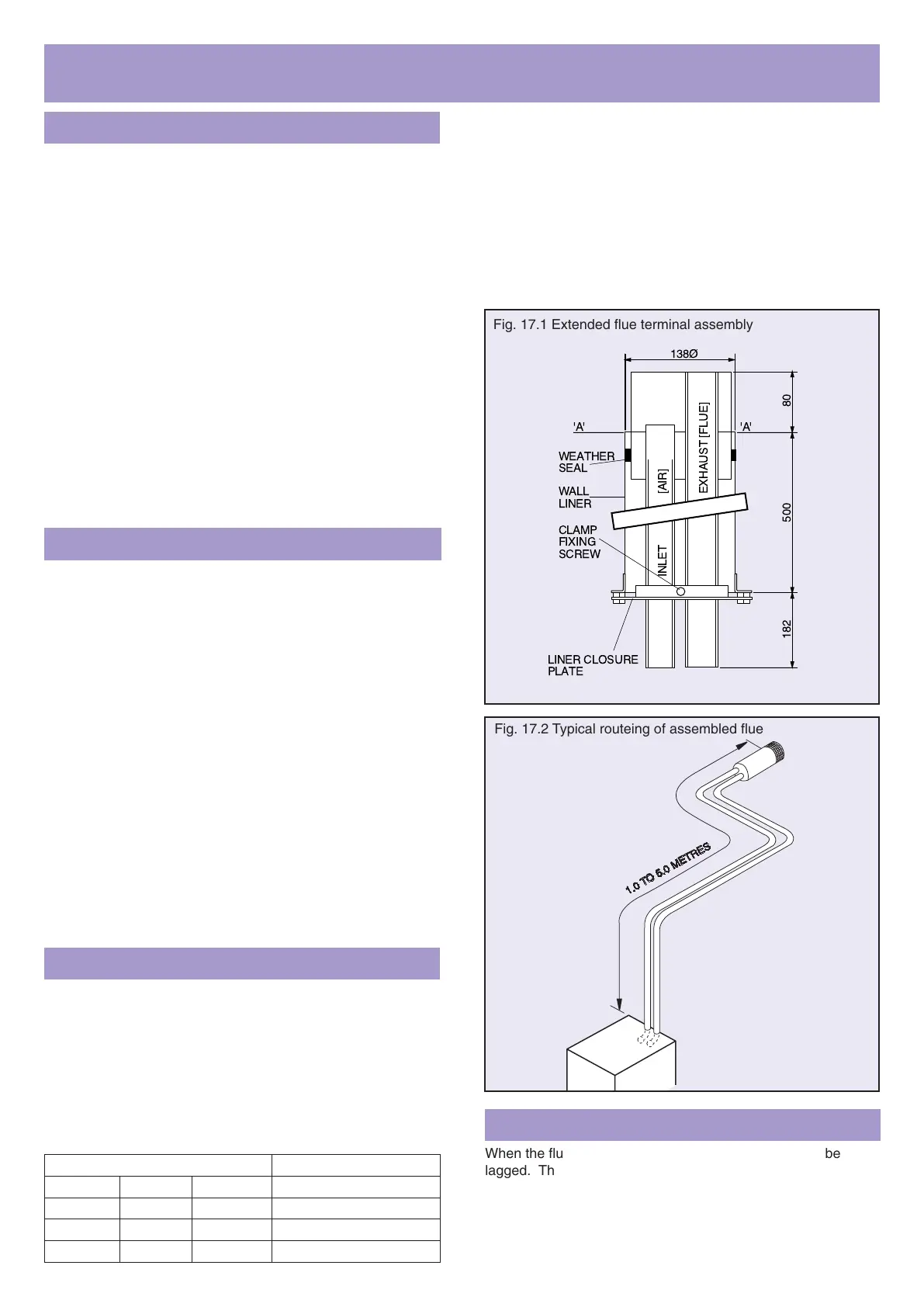

For flue and air pipes leaving the boiler vertically, refer to the

plan view in Fig. 17.7 (especially when planning to first fix the

extended pipes).

a Measure distances of flue pipe runs and note as a guide

to cutting pipes. The maximum length of each air/flue

pipe run must not exceed 5.0m (including a Horizontal

BF Terminal) if the maximum of 4 air pipe bends and 3

flue pipe bends is used – see Fig.17.2. There is no

minimum length.

If fewer bends are used between the appliance and the

flue terminal, then the maximum length of straight pipe

can be increased if required – see table below.

Any exhaust flue pipe accessible to occupiers of the

dwelling must be covered with protective ducts – Part

No. P360 is suitable.

The flue terminal assembly and the (hot) exhaust

products flue pipe must not be closer than 25mm (1") to

combustible material. If the flue pipes are run through a

timber wall or cupboard, or via a roof space with

wooden rafters; ENSURE A 25mm GAP IS LEFT

AROUND THE EXHAUST FLUE PIPE; OR EXTEND

THE PROTECTIVE DUCT.

Preparing Appliance & Protective Duct

a See Fig. 17.3. Slip a worm drive clip over both ends of

flexible inlet duct. Push one end of the duct over the

spigot on fan inlet and secure with clip.

If flue pipework leaves appliance vertically, remove 90°

elbow from flue pipe and engage plain end with flexible

duct. Secure with worm drive clip.

Insert flue pipe extension adaptor P338 into flue pipe

socket on boiler. Re-fit rear box (This can not be fitted

after vertical flue pipe has been fixed).

Note: If air/flue pipes run horizontally leftwards, align

bends and fit the first pipe length to the left, before

securing clamp with 70mm long screw.

b Move appliance to its final position. Note: Fixing the first

stage of the open vent pipe and F & E pipe is

recommended next (See section 11 of main instructions).

c With appliance in position, determine length of

protective duct required and if necessary adjust

standard length to suit – See Fig 17.5. Fix duct to wall

with screws and plugs provided. Temporarily set aside

duct cover.

Loading...

Loading...