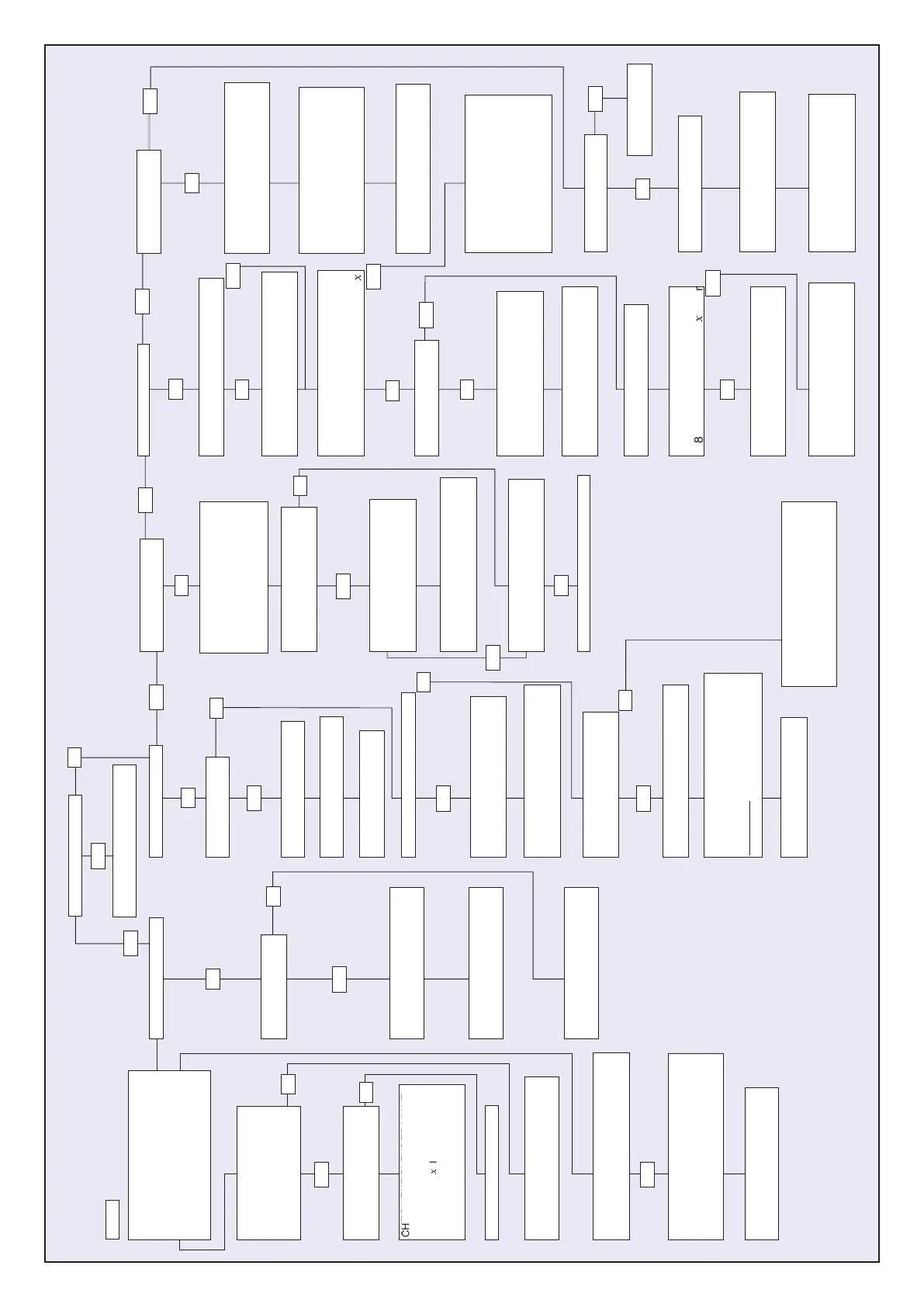

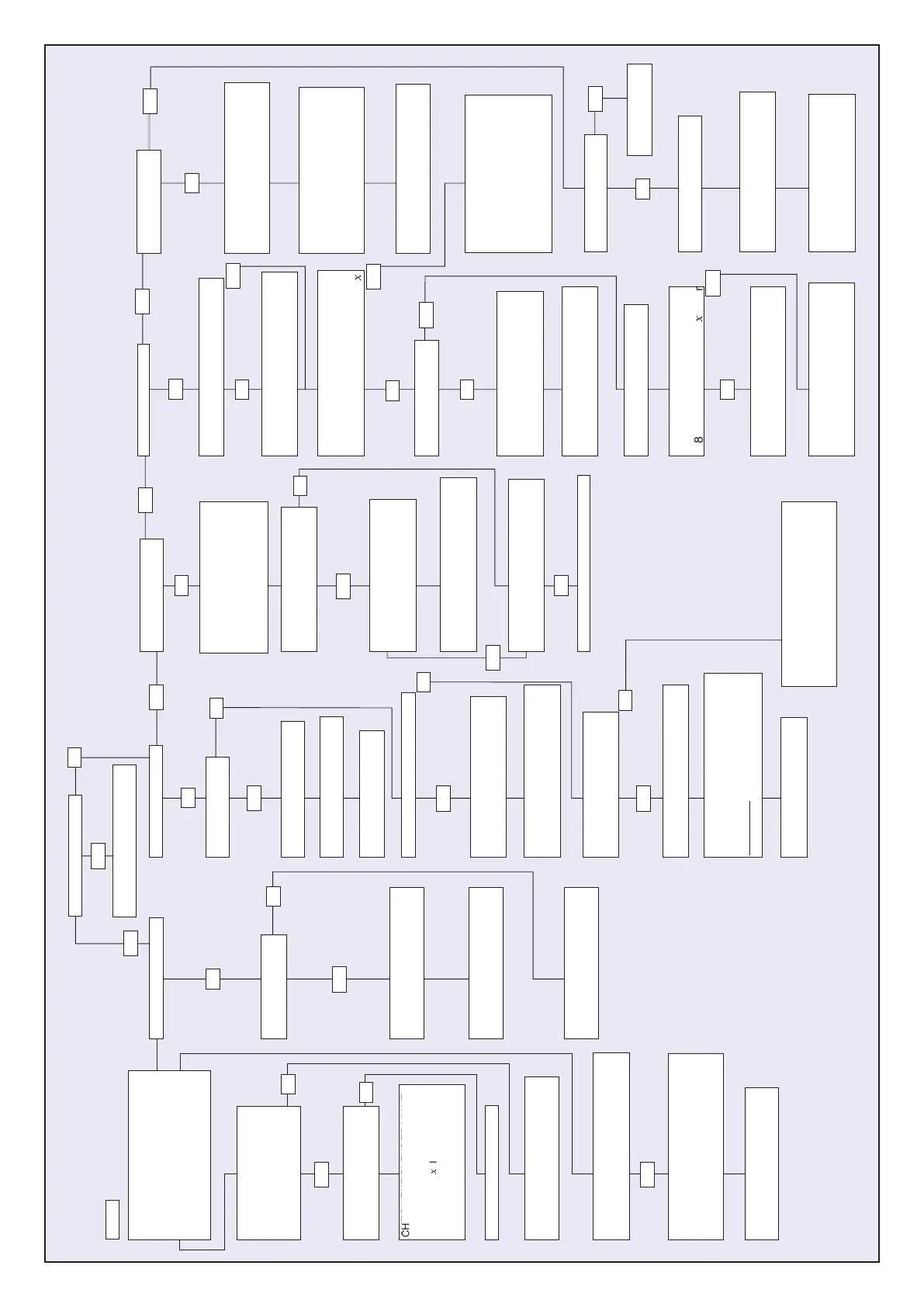

THE APPLIANCE WILL NOT:

IGNITE THE BURNER

DELIVER HOT PRODUCE

WATER CENTRAL

HEATING

DOES THE FLOW

SWITCH OPERATE THE

HE. PUMP IE 230V AT

TERMINAL 23 WHEN THE

BURNER IS NOT LIT

IS THE CYLINDER UP TO

THE CORRECT

TEMPERATURE

YES

CHECK THE BLENDER VALVE.

CHECK THE FLOW RATE IS

NOT GREATER THAN 121/MIN

IF THE FLOW IS POOR CHECK

THE INLET STRAINER AND

INCOMING WATER SUPPLY

CHECK THE FLOW SWITCH

RELAY ASSEMBLY, REPLACE IF

FAULTY

IS THE APPLIANCE/

PROGRAMMER/ROOMSTAT CALLING

FOR HEAT IE 230V AT TERMINAL 28

NO

START

NO

CHECK THE BOILER STAT

YES

CHECK THE COLD START STAT

(DOMESTIC PRIORITY STAT) IT WILL

NOT ALLOW CENTRAL HEATING

WHEN THE CYLINDER STORE

TEMPERATURE IS BELOW 65°C

IF OK CHECK PUMP AND

CONNECTIONS AT TERMINAL

25 AND N2

IS ORANGE NEON LIT

NO

IS THERE 230V TO

THE UNIT

YES

CHECK CIRCUITRY TO AND

AROUND NEON. IF CORRECT

REPLACE NEON.

NO

YES

CHECK FOR 230V EITHER

SIDE OF FILTER.

IF FAULTY REPLACE.

CHECK MAINS SUPPLY

LEAD/FUSE. REPLACE AS

NECESSARY.

DOES THE FAN RUN

NO

IS THERE POWER

TO THE FAN

YES

CHECK FAN CAPACITOR

AND WIRING FOR FAULT

CHECK FOR DAMAGE OR

BLOCKAGE TO THE FAN

REPLACE CAPACITOR/

REPLACE FAN

HAS THE LIMIT STAT TRIPPED

TEST FOR AND RECTIFY ANY

OVERHEAT FAULT, I.E.

DEFECTIVE BOILER STAT

YES

CHECK HEAT EXCHANGER PUMP

WORKING AND NOT AIR

LOCKED. REPLACE IF FAULTY.

CHECK BOILER

THERMOSTAT IS CALLING

FOR HEAT.

YES

CHECK CIRCUITRY TO FAN

FROM IGNITION CONTROLLER.

REMOVE IGNITION CONTROLLER

AND CHECK INTERNAL FUSE.

IF FAULTY REPLACE WITH

CORRECT 20mm FUSE,

I.E. 2A HRC

IF FUSE IS OK

REPLACE CONTROLLER.

NO

NO

NO

YES

CHECK IF PROGRAMMER/HEATING

SWITCH IS CALLING FOR HEAT.

CHECK SWITCH + WIRING FOR 230V

BETWEEN SWITCH/PROGRAMMER

AND BOILER STAT.

IS THE RED NEON LIT

SWITCH OFF WAIT 10 SECS

SWITCH ON

YES

NO

DOES SPARK

ELECTRODE SPARK

NO

DOES THE IGNITION

CONTROLLER GENERATE

A SPARK.

REMOVE THE BURNER AND

REPLACE (OR CHECK)

ELECTRODE. THE CORRECT

SPARK GAP IS 3.5/4.0mm

YES

REPLACE ELECTRODE IF FAULTY

(ADJUST ELECTRODE BY

MOVING EARTH POST ONLY).

PLACE THE ELECTRODE END OF

THE HT LEAD ON BURNER. IS A

SPARK TO THE BURNER VISIBLE?

REPLACE IGNITION CONTROLLER

NO

ENSURE THAT H.T. LEAD

IS PROPERLY CONNECTED

AT CONTROLLER AND THAT

THE WHITE EARTH WIRE IS

PUSHED HOME ON THE

ELECTRODE EARTH PLATE

NO

YES

IS GREEN NEON LIT

IS GAS PRESENT AT GAS VALVE

INLET PRESSURE TEST POINT

CHECK GAS IS CONNECTED AND

TURNED ON. CHECK FOR

OBSTRUCTIONS IN GAS LINE.

IS GAS PRESENT AT GAS VALVE

OUTLET PRESSURE TEST POINT

DURING IGNITION ATTEMPT

APPROX 4.5 mbar

CHECK FOR 230V AT

TERMINAL G1

CHECK OVERHEAT STAT AND

WATER LEVEL SWITCH AND

RECTIFY FAULT, E.G. REFILL

SYSTEM.

IF OK CHECK FOR 230V AT PIN

8 (BLACKWIRE) ON THE

IGNITION CONTROLLER

CHECK FOR FAULT AT GAS

VALVE OR AIR SENSE LINE.

CHECK FAN PRESSURE IN AIR

SENSE LINE IS BETWEEN 4.5

AND 5.2 mbar.

CHECK FAN, FLUE WAYS AND

INJECTOR HOUSING FOR

OBSTRUCTION AND RECTIFY.

IF SATISFACTORY CHECK COIL

ON GAS VALVE. REPLACE

COIL/GAS VALVE AS

NECESSARY.

NO

NO

YES

YES

NO

YES

YES

NO

YES

NO

YES

DOES APPLIANCE

REMAIN RUNNING

IF STUTTERING IGNITION IS

OBSERVED, CHECK ELECTRODE

AND CONNECTION AS IN

PREVIOUS COLUMNS.

IF SMOOTH IGNITION IS

OBSERVED BUT BURNER GOES

OUT AFTER APPROXIMATELY

3 SECONDS CHECK IGNITION

CABLE/ELECTRODE. REPLACE

AS NECESSARY.

IF IGNITION CABLE AND

ELECTRODE OK THEN REPLACE

IGNITION CONTROLLER.

NO

CHECK ELECTRODE AS IN

PREVIOUS COLUMNS. CHECK

ELECTRODE GAP DISTANCE

FROM BURNER FACE. IF NOT

APPROX. 13mm RECTIFY.

TURN OFF GAS AND USE

MIRROR TO CHECK FOR

STRAY HT SPARKING.

APPLIANCE

SATISFACTORY

YES

IS BOILER GAS RATE

SATISFACTORY

CHECK FLUE PIPES ARE

NOT BLOCKED

CHECK THAT THE FLUE PIPE

IS CORRECTLY CONNECTED

TO TERMINAL

CHECK THAT THE MAXIMUM

LENGTH OF AIR/FLUE PIPES

AND BENDS HAS NOT

BEEN EXCEEDED

NO

YES

5.0 (155

N

) or 4.0 mbar (140)

4.8.5.5 (155

N

) 3.8.4.4 (140)

CHECK THE BLENDER VALVE.

CHECK THE FLOW RATE IS NOT

GREATER THAN 12 L/MIN (140)

18 L/MIN (155

N

) IF THE FLOW IS

POOR CHECK THE INLET

STRAINER AND INCOMING

WATER SUPPLY

4

4.0mbar(140) or 5.0(155

N

)

3.8 - 4.4(140) 4.8 - 5.5(155

N

)mbar

Loading...

Loading...