3

These boilers require a natural gas supply of 1.6 to 2.0 cubic

metres per hour. Gas supply pipework of not less than 22mm

diameter should be run to the appliance and to within 300mm of

the gas valve (gascock) and should be installed in

accordance with BS6891:1988. (i.e. The pressure drop

between meter and appliance not to exceed 1mbar).

The gas connection to the appliance is Rp

1

/

2

(

1

/

2

in B.S.P.) Entry

holes are provided through the controls chassis.

The complete installation must be tested for soundness and

purged as described in the above standard and in accordance

with Corgi recommendations.

The appliance requires a 230V ~ 50Hz single phase 3A fused

electrical supply which must be installed in accordance with the

current IEE Wiring Regulations and any Local Regulations

which apply. Detailed wiring instructions are given in Section 10.

Power consumption is approximately 140W for the appliance,

with the Central heating pump rated at an additional 40W to

88W depending upon pump speed.

WARNING : THIS APPLIANCE MUST BE EARTHED

Note: This appliance may be installed in any room or internal

space, although particular attention is drawn to the

requirements of the current IEE Wiring Regulations, and in

Scotland, the electrical provisions of the Building Regulations

with respect to the installation of the appliance in a room or

internal space containing a bath or shower. Where a room-

sealed appliance is installed in a room containing a bath or

shower, any electrical switch or appliance control, utilising

mains electricity should be so situated that it cannot be touched

by a person using the bath or shower.

4. ELECTRIC SUPPLY

3. NATURAL GAS SUPPLY

The appliance must be installed on a flat floor capable of

supporting the weight of the unit when full of water – up to

185kg. It should be sited to minimise the length of flue and to

avoid long hot water pipe runs.

The extended flueing capability enables the appliance to be

sited well away from an outside wall, thus installation in a first

floor cupboard or compartment, basement, utility room or

kitchen are all feasible locations. The appliance must not be

sited outside or in any outhouse where it could be exposed to

the weather.

The location chosen must permit the provision of a satisfactory

external flue termination. The location must also provide

adequate space for servicing and air circulation.

If floor settlement is likely due to the weight of the appliance,

ensure that pipework design is able to accommodate this.

When using an extended flue system it is essential to fit

protective ducting (such as that supplied in the extended flue

kits) in order to prevent direct contact with the hot flue pipe.

General requirements for cupboard/compartment installations,

including airing cupboards, are given in BS6798. Specific

requirements for Powermax installations are given below.

a The compartment must be ventilated at high and low

level in accordance with BS5440:Part 2 and Section 7

of these instructions.

b The compartment shall be a fixed rigid structure large

enough to allow it and the boiler to be inspected and

serviced. A minimum width between the door jambs of

550mm (21in) must be provided.

c Internal surfaces should be non-combustible or lined

with non-combustible material. Examples of non-

combustible materials having a fire resistance of not

less than 0.5 hour are plaster skimmed plasterboard,

and fireproof boarding. The floor need not be lined.

Doors or shelves made from combustible material, e.g.

wood must be at least 75mm from the front or top of

the boiler.

d The door of an understairs cupboard shall have a

BS476:Part 8 fire resistance of not less than 0.5 hour;

and air vents must be direct to outside air.

e The flue pipe must be protected by the ducting supplied

by Baxi UK or by another no less suitable non-

combustible enclosure.

f Householders should be discouraged from storing

clothes etc on the boiler itself. A removable shelf at

least 75mm above the boiler is acceptable.

Detailed recommendations for flueing are given in

BS5440:Part 1. The following notes are intended to give general

guidance. The appliance must be installed so that the flue

terminal is exposed to the external air, preferably on a clear

expanse of wall. Acceptable positions are indicated in Fig.5.1.

Avoid positions where the terminal is adjacent to projections;

particularly immediately under a balcony, inside a re-entrant

position, or immediately adjacent to a drain pipe.

If the appliance is fitted under a ventilator or opening window,

the terminal must be at least 300mm (12in) from any part of the

window or ventilator, and in accordance with BS5440:Part 1.

Requirements for horizontal

balanced flue terminations

Compartment Installation

Flue Protection

General

5. SITING THE APPLIANCE

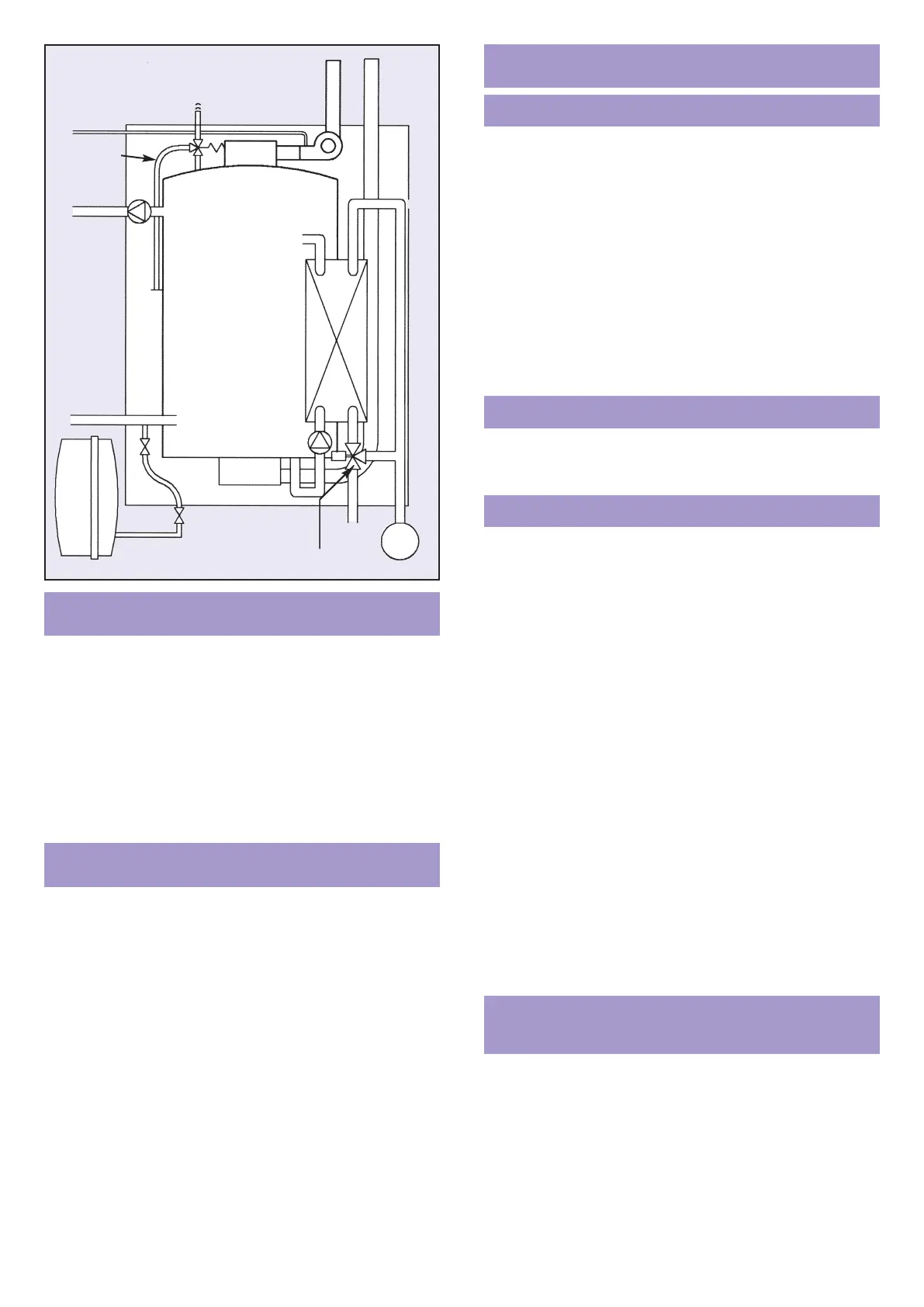

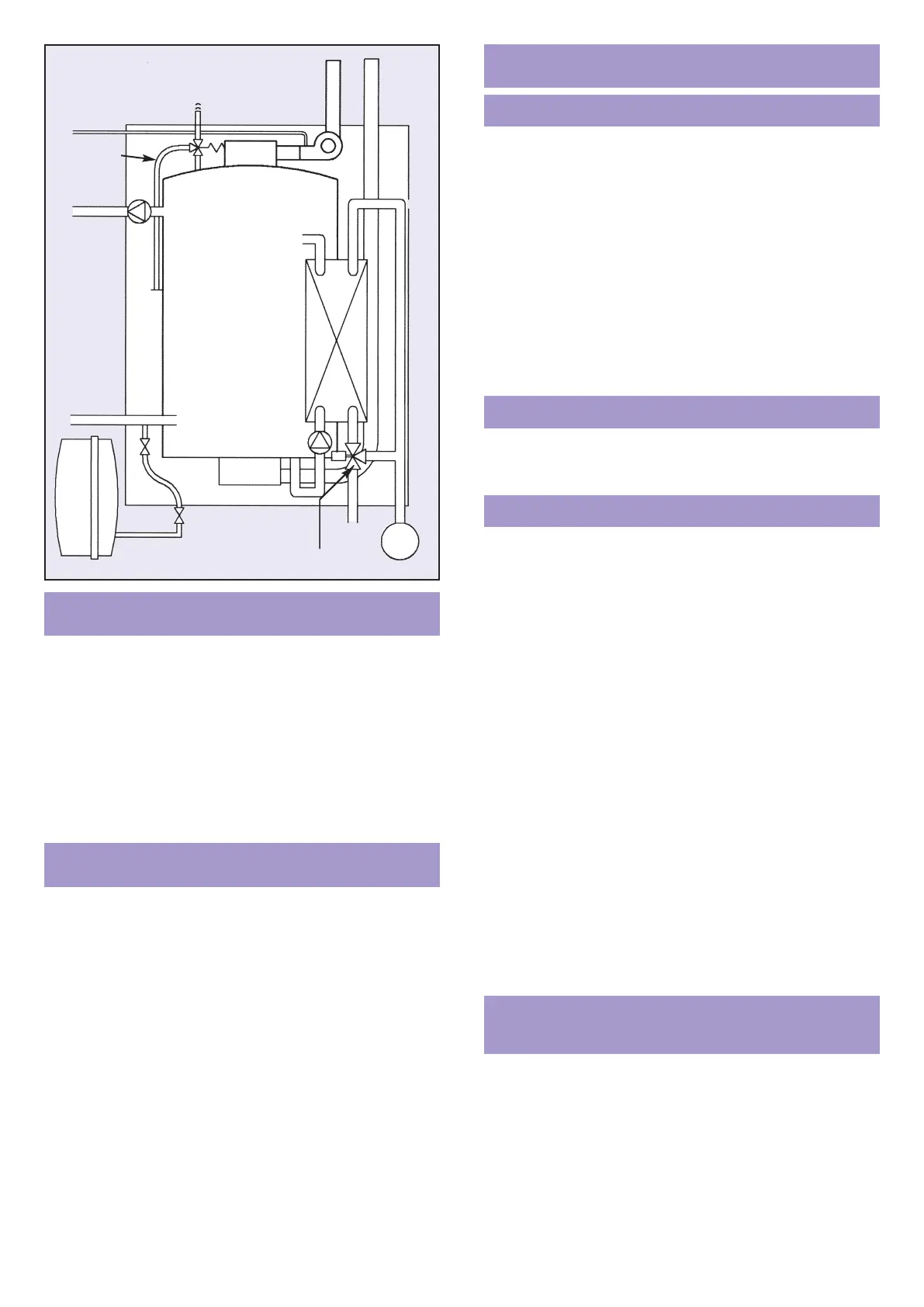

Powermax

Sealed System

Schematic

AIR VENT

PRESSURE

RELIEF

CH FLOW

CH RETURN

Loading...

Loading...