17

Air/Gas (Solenoid) Valve Fig.12.1 & 13.4

a Refer to General above.

b Disconnect gas service cock at the union and

disconnect the outlet pipe at the union nut on flared

fitting.

c Remove screw holding bracket. Disconnect the wiring

leads and remove valve. Remove bracket.

d Remove the flared fitting from valve outlet and transfer

to new valve. Note: Threads on valve outlet must be

resealed with a sealant complying to BS5952.

e Fit new valve in reverse order. Ensure that inlet and

outlet connections are fully gas tight.

Procedure for checking/setting S.I.T. Sigma 848 Air/Gas

Ratio Valve

Do not attempt these adjustments unless you have both

the use of a correct specification of digital manometer

and the relevant training.

i Using a differential manometer connect the positive side

of the manometer to the gas valve outlet pressure

tapping and the negative side to the air pressure sense

line using a tee piece.

ii Start the boiler, ensure that the inlet pressure is

adequate, i.e. ~20 mbar and bring thermal store up to

working temperature (above 60°C). Read the

differential pressure across the micromanometer (ΔP).

iii If reading is outside the range

_

0.13 to

_

0.16 mbar,

carefully remove the servo governor cap and adjust the

value of ΔP to

_

0.13 (±.03) mbar (i.e. the gas pressure

is 0.13mbar

less

than the air sense pressure) .

iv Replace cap and tighten.

v Re-connect sense line tubing to valve.

vi Check burner pressure is approximately 3.8 to 4.4 mbar

(140) or 4.8 to 5.5 mbar (155x). NB The longer the flue

system the lower will be the expected pressure. Very

low values e.g. 3.0 mbar, indicate an obstruction in the

air supply; a high pressure e.g. >6.0 mbar indicates a

blockage in the flue pipe or sump - see fault finder chart

on page 12. In case of difficulty, consult The Technical

Helpline 08706 049049.

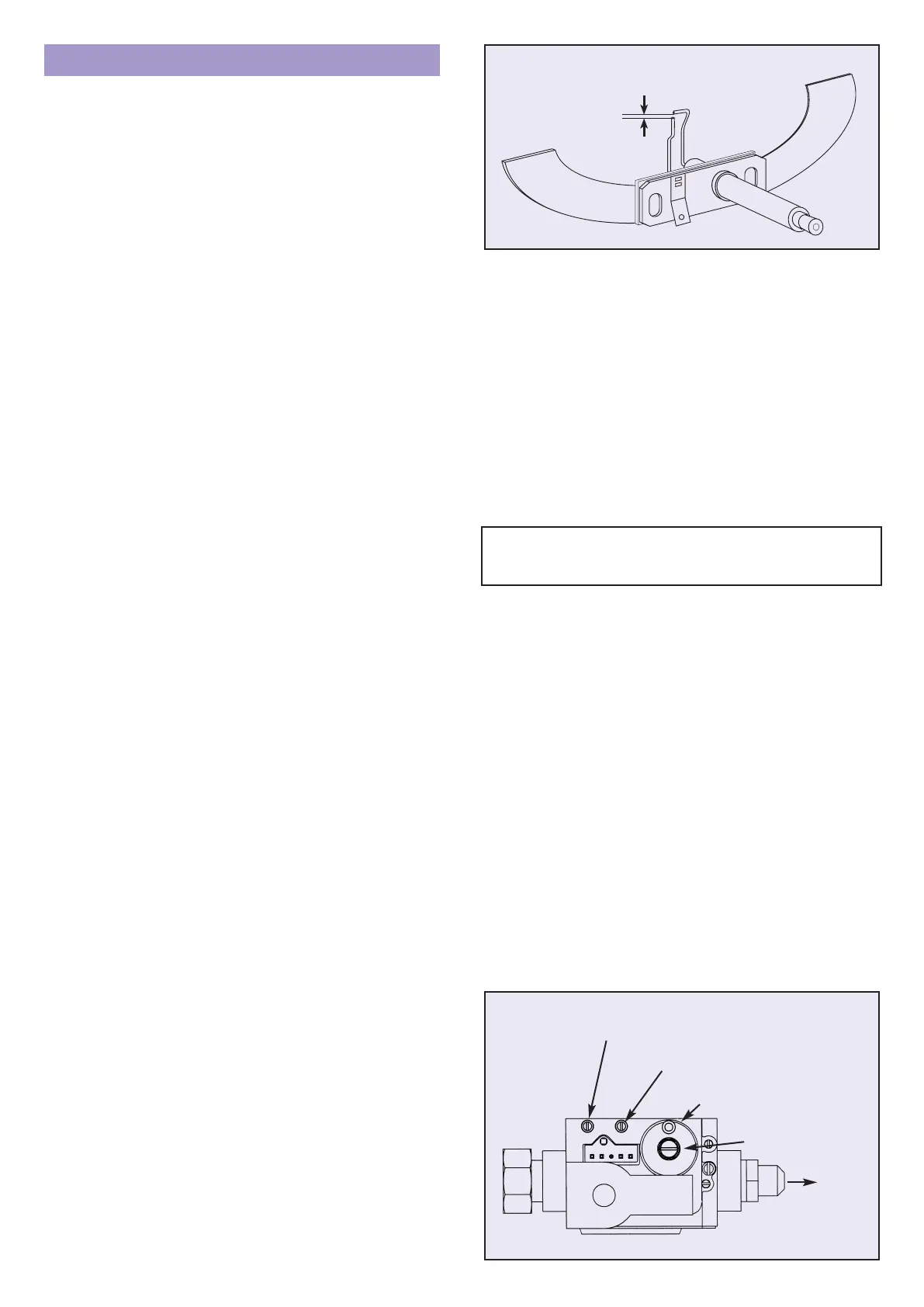

Fig. 13.3 ELECTRODE GAP

Fig. 13.4 S.I.T. SIGMA 848 AIR/GAS RATIO VALVE

Component Exchange Procedures

Fig. 13.1

General Notes

Isolate gas and electricity supplies. To gain access remove front

panel and top cover as described in section 9 and fig 9.1.

Components are replaced in reverse order unless otherwise

stated.

To remove switch panel undo the single fixing screw noting how

lower edge of panel locates for reassembly. Taking care not to

damage the wiring, the panel can be attached for servicing

through the 2 holes in its corners to the lid fixing nutserts using

the lid fixing screws.

Note that any damaged gasket or seal must always be

renewed.

Full Sequence Ignition Controller Fig.12.1

a Refer to General above.

b Pull off H/T lead from connection at top of controller.

c Pull out the ‘Molex’ connector plug.

d Remove top screws, and remove controller.

HT Lead Fig.12.1.

a Refer to General above.

b Disconnect lead at electrode and at ignition controller.

Burner Fig.13.2

a Refer to General above.

b Remove two M4 screws holding fan to burner, also air

inlet elbow retaining screws. Pull fan away from burner

and rest on ledge formed by cross brace. Disconnect air

sense tube and check that it remains supple and free

from splits etc. Release both union nuts on gas pipe.

Note: Hold injector with second 19mm AF spanner to

prevent injector being disturbed. Swing pipe clear of

burner.

c Remove 8 screws from burner flange and lift burner out.

Note: When re-tightening union nut on gas feed pipe

hold injector securely with second spanner to prevent it

being disturbed. Always fit new flange gasket P507.

d Check for soundness at gas supply pipe unions.

Injector

a Refer to General above.

b Release union nuts on gas feed pipe.

c Unscrew injector anti-clockwise. Re-seal new injector

with a sealant complying with BS 5952.

d Check joints for soundness.

Spark Electrode Fig.13.3.

a Refer to General and Burner above.

b. Remove burner/fan.

c Disconnect the H/T lead. Remove the screws and

washers. Gently pull the electrode away from the

combustion chamber. Fit new electrode and gasket and

check that the spark gap is as shown.

d Replace burner using new gasket, and check

operation of appliance.

e Check for soundness at gas supply pipe unions.

Fan Fig.12.1 & 12.2

a Refer to General above.

b Disconnect fan leads from small terminal block.

c Remove screws retaining air inlet elbow. NB 2mm A/F

hexagon key required.

d Remove two M4 screws and pull the fan gently forward.

e Ensure fan is fitted with new O-ring supplied.

Reassemble and check for soundness, especially air

inlet elbow.

Neon Lights and Switches Fig.12.2

a Refer to General above.

b Push the neon light or switch from the back through the

switch panel and replace in reverse order making sure

the leads are correctly replaced – See wiring diagrams

Fig.10.

OUTLET PRESSURE TEST NIPPLE

AIR SENSE NIPPLE

GOVERNER CAP

INLET PRESSURE TEST NIPPLE

OUTLET

Loading...

Loading...