5

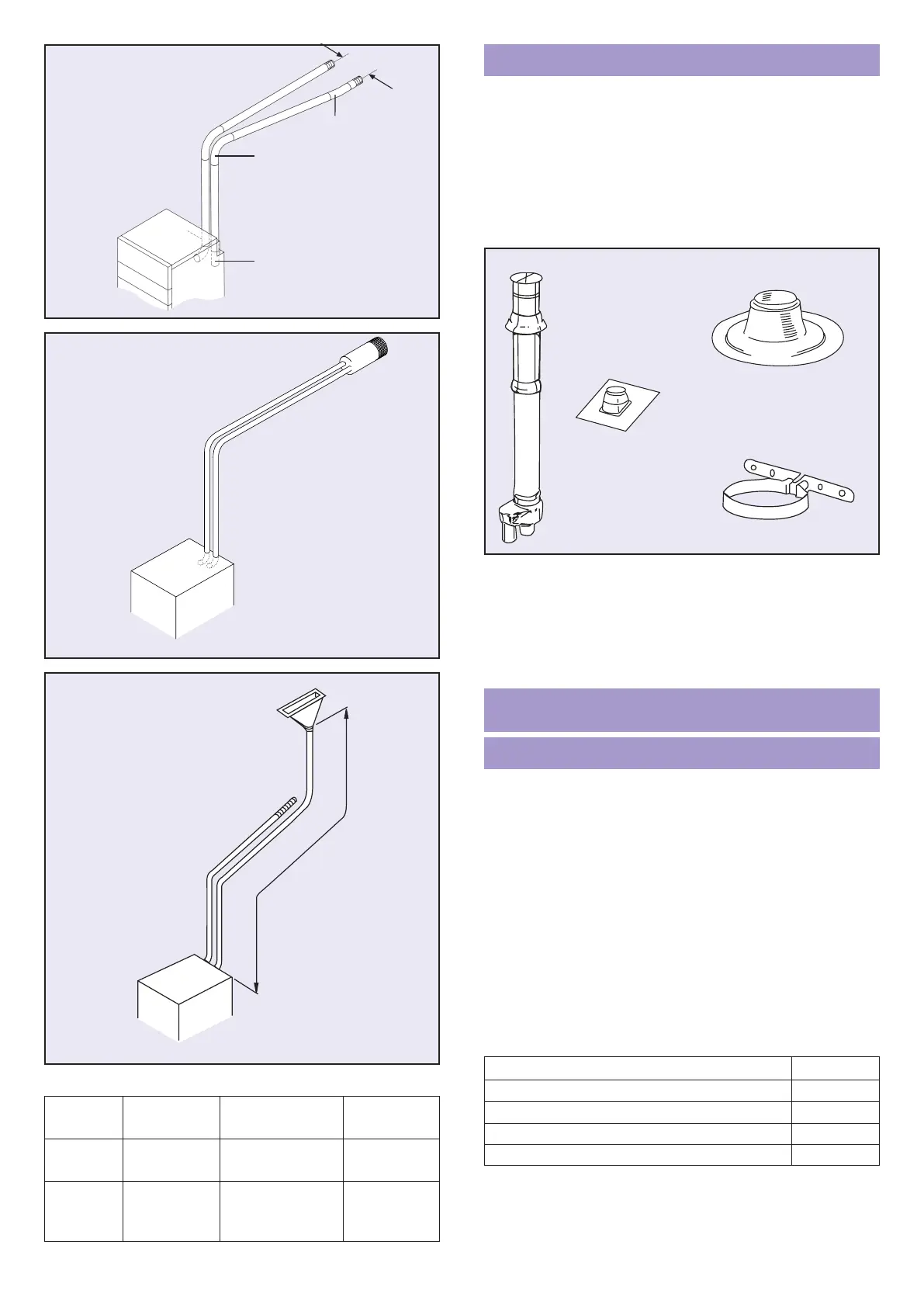

Fig. 6.2

Mini terminal

flue system

Example of rearwards

flueing to achieve

minimum 300mm

distance between

terminals

Maximum permitted flue run

of 9.0m total length (including

one 90° bend and one 170°

offset Bend in the flue pipe).

Fig. 6.3

Typical routeing of

extended balanced flue

Fig. 6.5

Typical routeing of

ridge terminal flue kit

Note that

the length of

the air inlet

pipe must not

be less than

0.5 x length

of flue pipe

1.5 TO 4.0 METRES

1.5 TO 5.0 METRES

[STANDARD KIT]

1.5 TO 7.0 METRES

[EXTENDED]

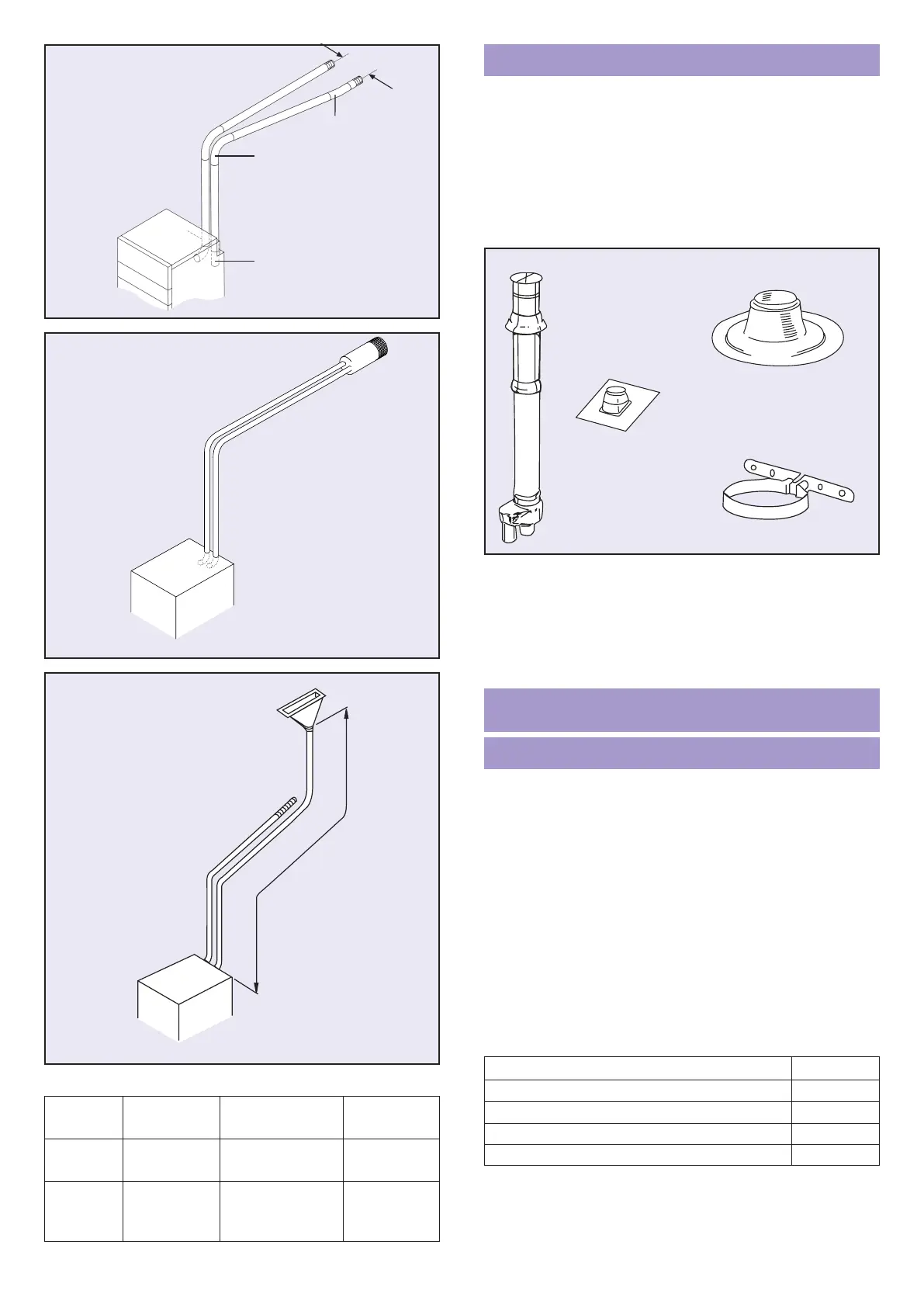

Vertical RS Flue System

The Powermax Vertical RS flue system offers an unobtrusive

balanced flue terminal as an option for both pitched and flat roofs.

The vertical roof terminal Part No. P230 provides a combined air

intake and combustion gas outlet in a concentric arrangement.

Below the roof the terminal changes into a twin pipe system.

Separate roof flashing units should be ordered (specified) for

pitched or flat roofs. Roof pitches from 15° to 55° are catered for

by selecting one of three pitched roof flashing units.

P231 for pitches 15° to 25° P232 for pitches 25° to 45°

P233 for pitches 35° to 55° P236 for flat roofs

To connect the Powermax to the vertical terminal a kit Part No.

P246 is required. This contains a range of extension air/flue

pipes and bends to enable the terminal to be sited up to 2.5m

from the appliance. The maximum overall length of the

complete flue system must not exceed the limits indicated for

extended balanced flue systems, however the length of the

vertical terminal itself can be disregarded. Complete fixing

instructions are provided in each kit.

The Mini Terminal Flue system provides an alternative

arrangement to the standard (140mm diameter) balanced flue

terminal.

Separate 65mm diameter air inlet and flue terminal assemblies

can be positioned in different locations on the same wall subject

to similar wind conditions. See Fig. 6.2.

They are available in a small range of colours chosen for their

compatibility with typical external building materials.

Code.

A Matt Black

(standard finish)

D Red Brick

B Stone

(also suitable for yellow stock brick)

E Slate

C Light Brick F White

Each terminal requires a hole of 65mm diameter to be core

drilled through the external wall.

Flue kits are available as listed below. Each kit contains all the

components needed for a complete system including full fixing

instructions.

Kit No.

* For sideways flueing

WARNING – The flue pipe becomes very hot when appliance

is working. Householders should be warned not to touch

exposed pipe e.g. beyond protective duct within loft.

The flue pipe should be insulated or ducted if accidental

contact is likely.

Description

MINI TERMINAL FLUE

P231/232/233

P230

P236

P234

Fig.6.6 VERTICAL FLUE COMPONENTS

FLUEING RESTRICTIONS – RIDGE TILE TERMINAL

Number of Bends Pipe Length

Application Components 90° or 135° (metres)

Standard Air Inlet 2 1.5 minimum

Kit Flue 3 1.5 minimum

Extended Air Inlet 2-3 1.5 to 4.0

Inlet & Flue 3 max 1.5 to 7.0

Flue

1m Mini Terminal BF kit* P271

3m Mini Terminal BF kit P273

5m Mini Terminal BF kit P275

7m Mini Terminal BF kit P277

9m Mini Terminal BF kit P279

Loading...

Loading...