13

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

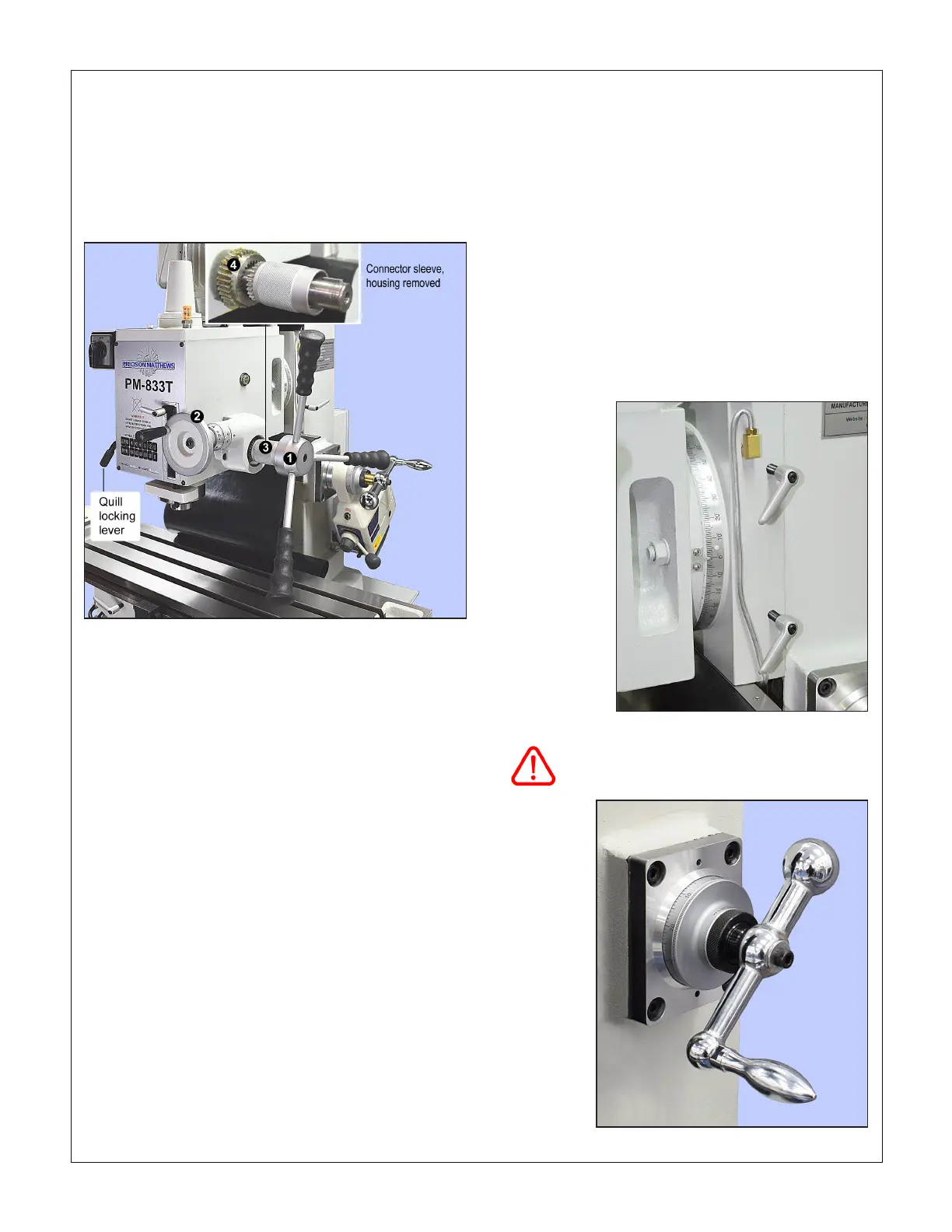

CHANGING HEADSTOCK ELEVATION (Z-AXIS)

The headstock is raised and lowered by the hand crank,

Figure 3-8. The crank handle disengages from the lead-

screw by spring action. Press the handle in to engage.

Before moving the headstock, be sure that:

1. The exible oil line to the headstock is tucked inside

the column, Figure 2-1.

2. The clamp levers have been loosened, Figure 3-7.

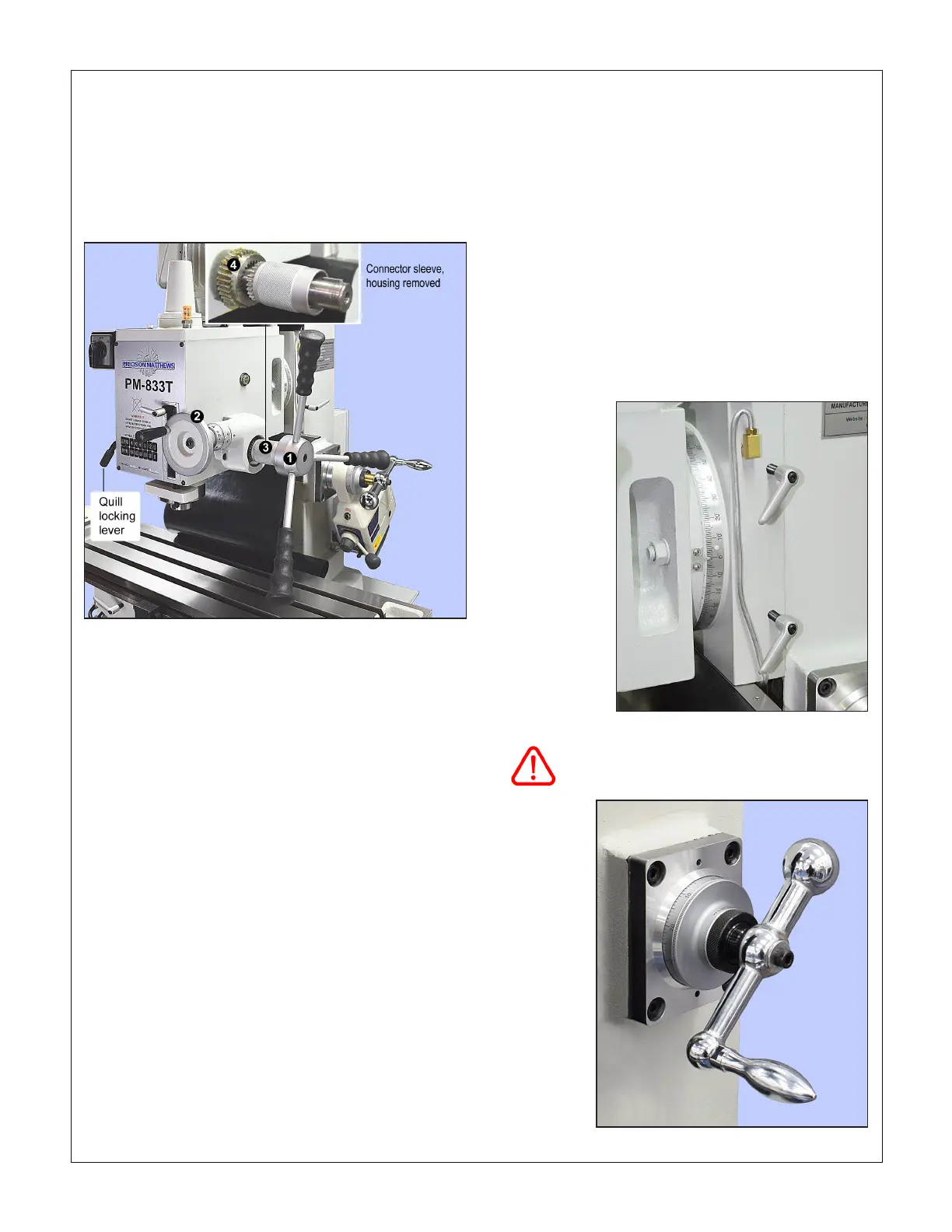

QUILL DOWNFEED

The quill is controlled in two dierent ways, coarse and

ne, Figure 3-6.

In the drilling mode, coarse feed, the mill functions like

a standard drill press — lower the quill using any of the

three downfeed levers to rotate the lever hub count-

er-clockwise.

Figure 3-6 Quill downfeed controls

(File photo PM-833T) Lever hub (1) is full-time connected to the pinion

shaft controlling the quill rack. The ne control handwheel (2) drives

worm gear (4), which is free to rotate — doing nothing to the quill —

unless it is coupled to the pinion shaft by connector sleeve (3). Teeth

on the knurled sleeve, which is keyed to the pinion shaft, mesh with

inner teeth on worm gear (4).

Coarse feed

For drilling operations, slide the knurled connector

sleeve to the right. If desired, set the depth stop, Figure

3-1.

Fine feed

For milling operations calling for precise, repeatable

control of tool depth, slide the knurled connector sleeve

left to engage the ne-feed worm gear.

Rotate the ne control handwheel to raise or lower the

quill. Before switching to ne control, it is usually a good

idea to run the depth stop up to the top. Lower the quill

by turning the handwheel clockwise, positioning it pre-

cisely by counting divisions on the graduated dial.

If you are counting divisions be aware of backlash in

the worm drive. This means that the handwheel must

always be turning in the same direction throughout

the entire process, from setting a reference level to sub-

sequent cutting passes at specic depths.

Be sure to loosen the clamp levers before

moving the headstock, especially under

power

Figure 3-7 Headstock clamp levers

Bear in mind that the quill is spring-loaded. This calls for

care when releasing the quill locking lever prior to repo-

sitioning the quill downward. If the ne control knob has

been allowed to disengage (backed o counter clock-

wise), the quill will jump up by 0.01” or more. To avoid

this, make sure the ne control is rmly clockwise, lightly

loading the quill rack, before releasing the locking lever.

Figure 3-8 Headstock adjust handle

Loading...

Loading...