14

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

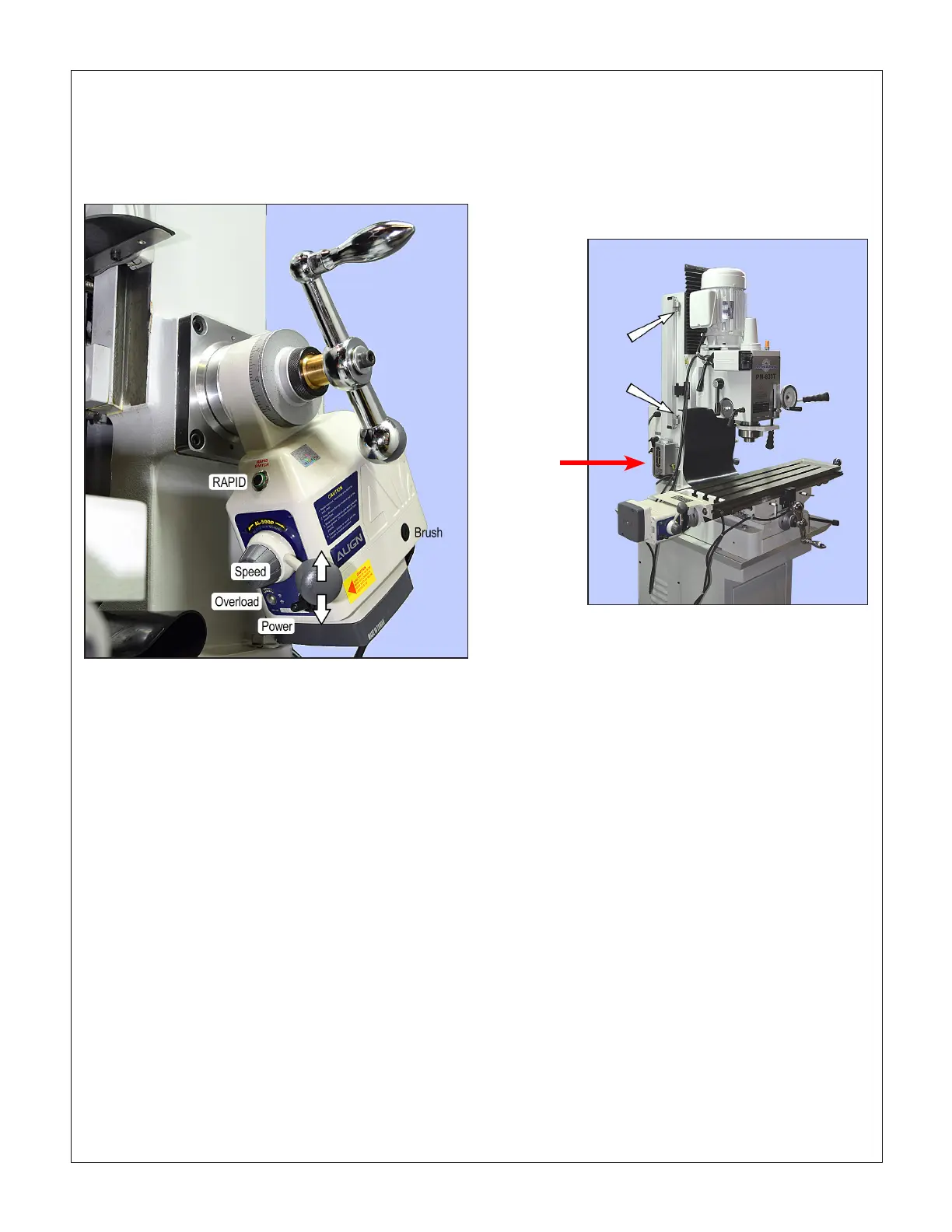

Figure 3-9 Headstock power assist

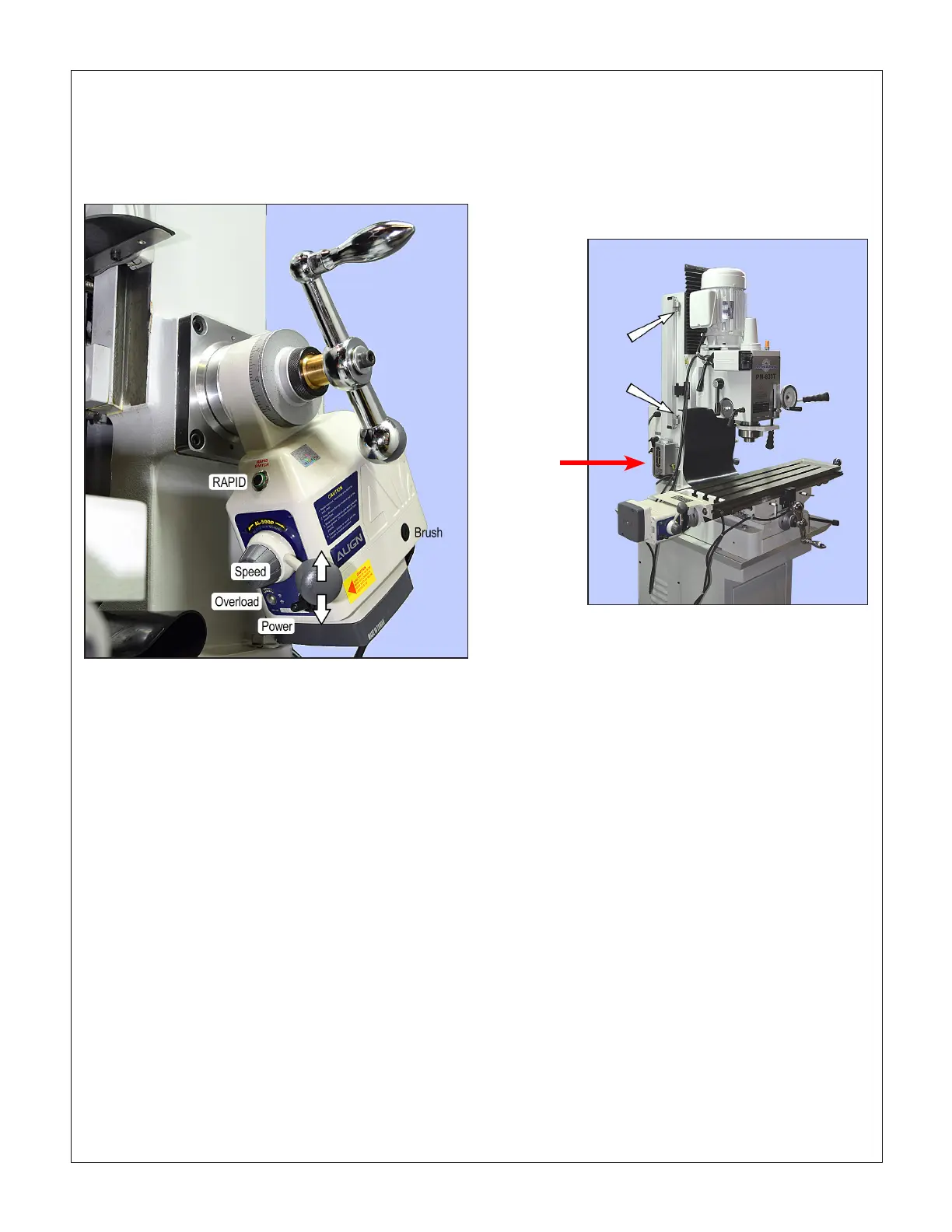

Figure 3-10 Z-axis limit stops (File photo PM-833T)

Z-axis power assist (option)

The power assist unit, Figure 3-9, allows the headstock

to be raised and lowered in the usual way, plus it pro-

vides the ability to downfeed under power. This feature

can be used to reduce workload in many routine opera-

tions including drilling, honing and hole boring.

A separate manual is provided for the power assist unit,

manufactured by the ALIGN company (Taiwan).

To raise or lower the headstock under power:

• Check and adjust the limit stops as desired, Figure

3-10.

• Set the speed adjust knob, starting with a low speed,

counter clockwise.

• Switch on the power unit. The LED in the "RAPID"

push-button should light.

• Set the direction lever UP or DOWN.

• Adjust the speed as desired.

• For highest speed motion, press the RAPID push-but-

ton.

If the unit draws 3 Amps or more for 10 seconds, the

overload circuit breaker will pop out, cutting power. Cor-

rect the cause of the problem, then press in the circuit

breaker to restore power.

Positioning the headstock

A micrometer collar graduated in 0.001" divisions, 0.1"

per revolution, allows the headstock elevation to be ac-

curately set when adjusted by hand.

If the mill is not equipped with a Z-axis digital readout

(DRO), the headstock can be accurately positioned by

counting whole turns and divisions, keeping leadscrew

backlash in mind. This means that headstock motion

must always be in the same direction when approach-

ing the point of reference, then onward by a specied

amount to the desired location.

One-shot

lube

reservoir

Limit

stops

Loading...

Loading...