16

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

X & Y-AXIS POSITIONING BY COUNTING

DIVISIONS

For all spindle positioning operations, with or

without DROs, avoid using the quill lock. Retract

the quill fully, then adjust the headstock elevation

instead.

Why? On practically all vertical mills, including the heavi-

er knee mills, locking the quill may oset the spindle by a

few thousandths of an inch. If the edge of the workpiece

has been “found” in the quill-locked condition, this will af-

fect placement of holes drilled thereafter. Instead, lower

the quill with the ne downfeed control. This is worm

driven, so it stays where it’s put without locking.

Note: This does not apply to operations calling for pre-

cise depth control, such as milling. For such operations

the quill must be locked to maintain a given depth of cut.

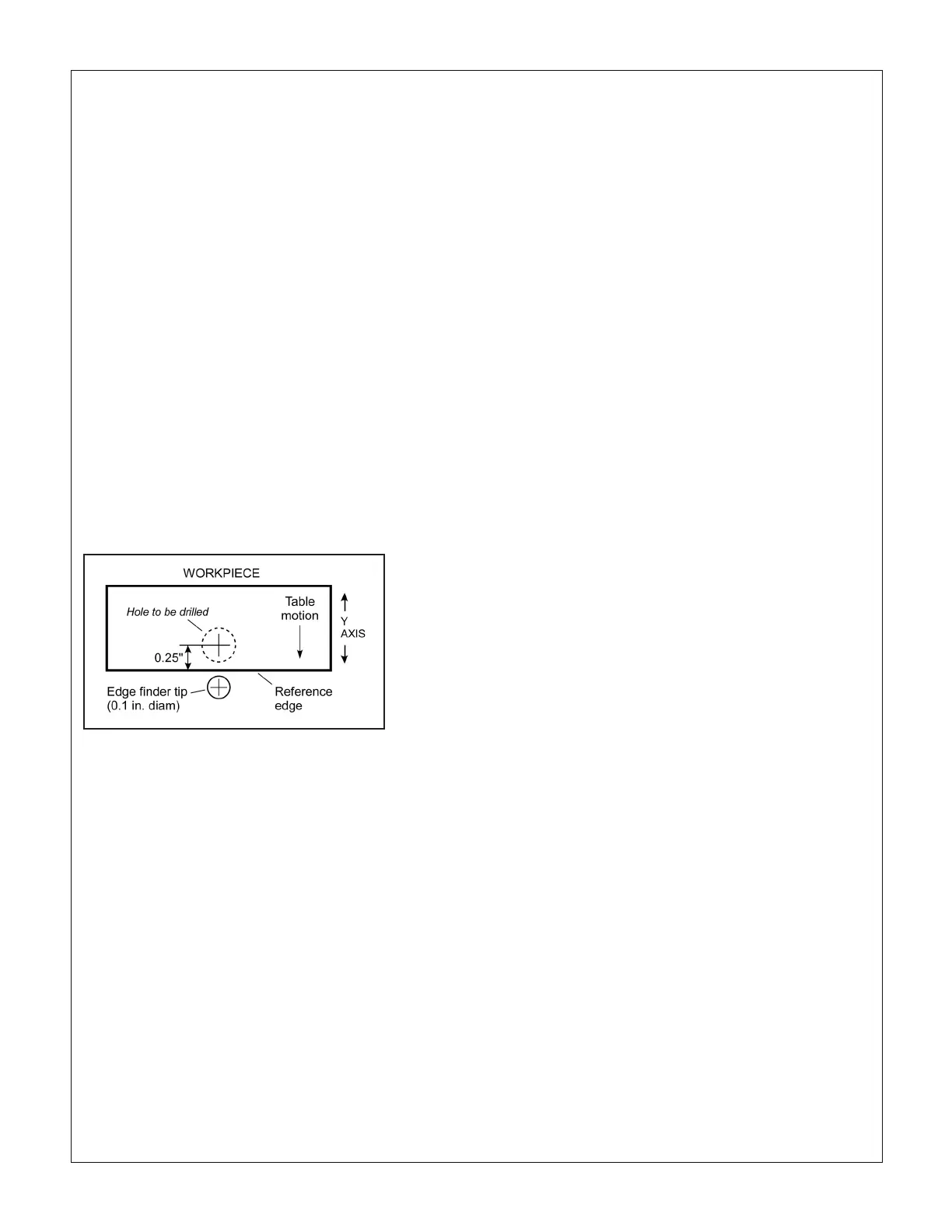

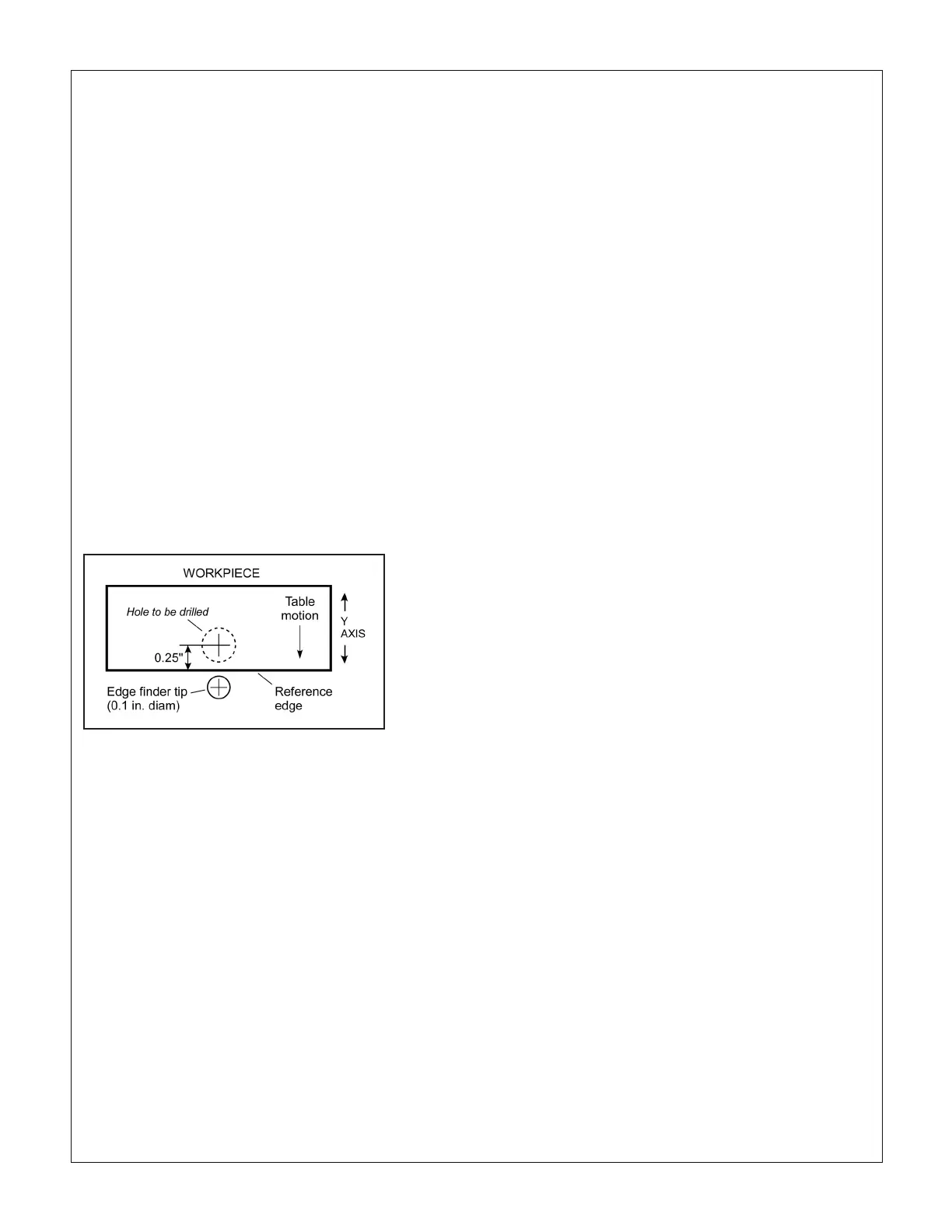

Figure 3-15 is an example of Y-axis positioning by count-

ing dial divisions. A hole is to be drilled 0.25” back from

the front edge of a workpiece in a vise, or otherwise

clamped to the table.

1. Install an edge-nder in collet or chuck (a tip diame-

ter of 0.2” is assumed).

2. Lock the X-axis by tightening the clamp levers (op-

tional).

3. If the reference edge is already to the back of the

spindle centerline, do nothing; if not, rotate the Y-axis

handwheel clockwise to send the workpiece back-

wards (toward the column).

4. Engage the ne downfeed.

5. With the spindle running, lower the quill as necessary

using the ne downfeed handwheel; bring the table

slowly forward (counter-clockwise), stopping at the

point where the edge-nder just makes contact with

the workpiece — the tip will jump out of line. Stop the

spindle.

6. While holding the Y-axis handwheel to prevent any

movement, zero the dial.

7. Raise the quill, then rotate the handwheel exactly

one full turn counter-clockwise (0.1”) to bring the

reference edge forward to the spindle centerline.

Figure 3-15 Spindle positioning example

8. Rotate the handwheel counter-clockwise an addi-

tional 2-1/2 turns to bring 50 on the dial opposite the

datum; the spindle is now 0.25” behind the reference

edge, ready for drilling.

Loading...

Loading...