25

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

The following 6 pages are standalone instructions

for power feed installation. Figure numbers are not

in sequence with earlier pages of Section 4.

INSTALLING THE TABLE POWER FEED

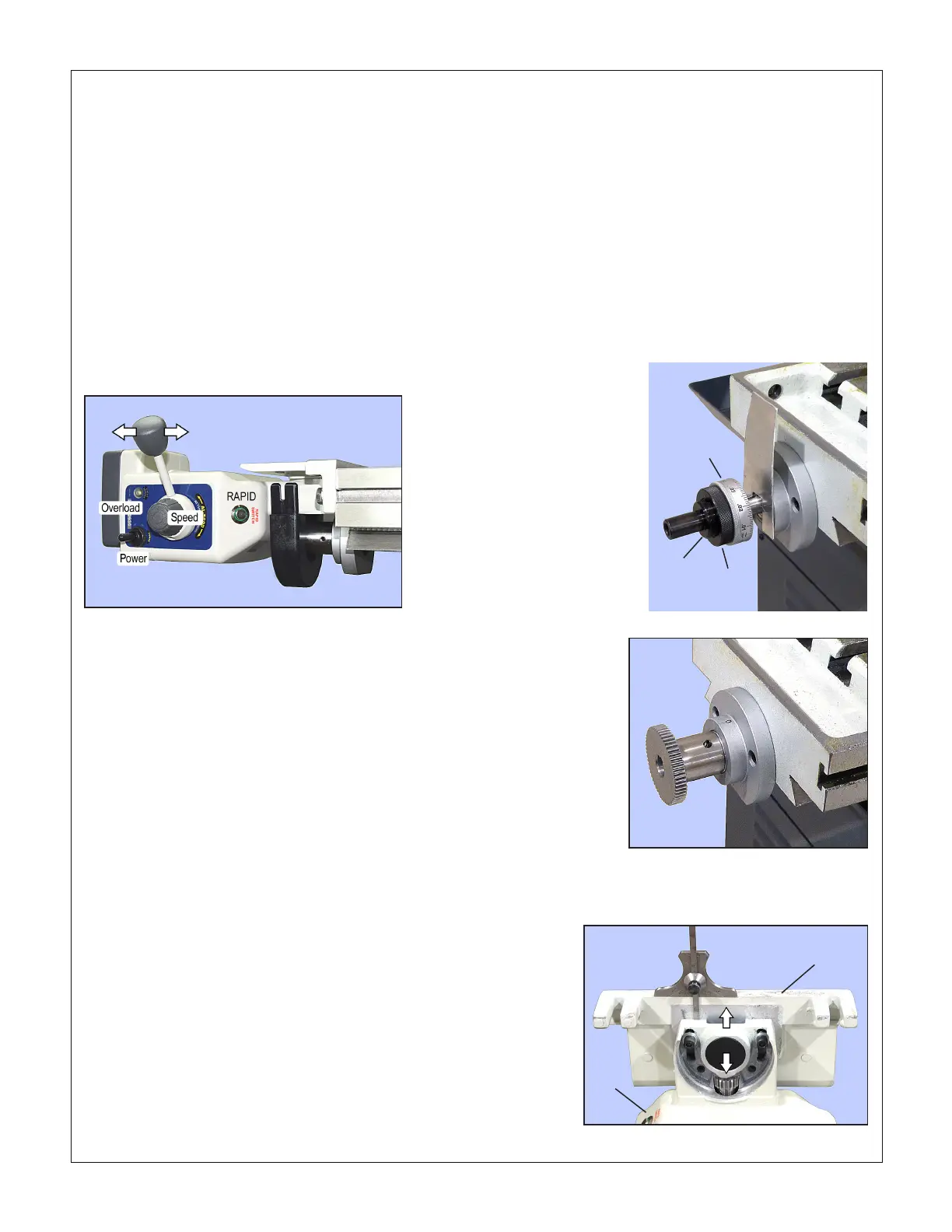

The Precision Matthews Table Power Feed kit is specically

engineered for the PM-833TV mill, Figure 1. Power required

is 110V, 60 Hz.

Figure 1 Table (X-axis) Power Feed unit

Installation of the table power feed is straightforward, calling

for standard shop tools such as a power drill, plus two sizes

of metric taps: M5 and M8.

Kit contents

• Motor unit

• Mounting bracket

• One 3 x 15 mm key

• Gear (for leadscrew), Figure 3

• Gear cover, Figure 7

• M8 hex head screws (mounting bracket to table)

• M6 screws (motor to mounting bracket)

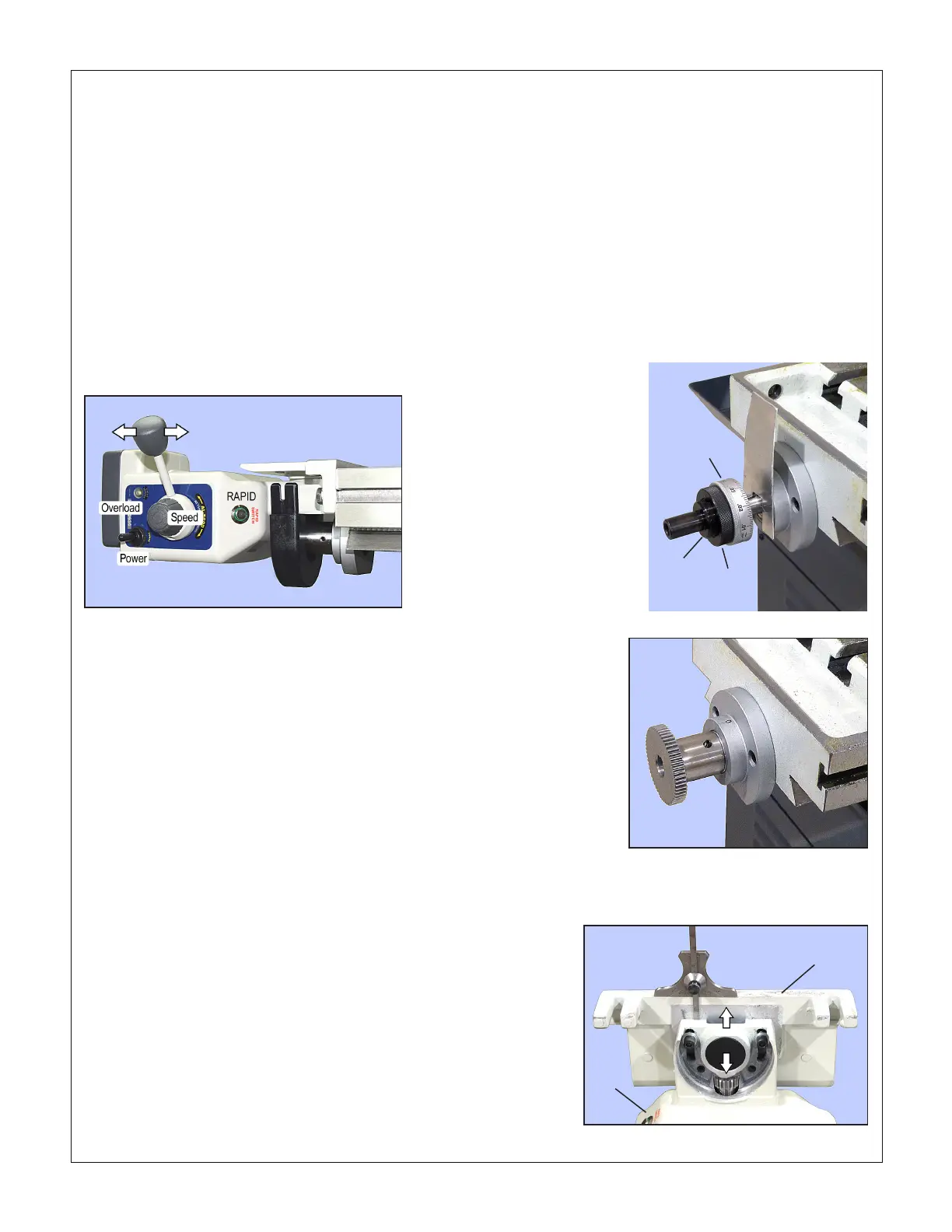

Figure 2 Remove LH

end components

If you need to use pry

bars — such as a pair of

at-blade screwdrivers

— protect the bearings

and ange with scrap

metal, not supplied. None

of these components is

reused when the power

feed is installed.

Dial

Knurled

ring

Threaded

bushing

Figure 3 Install gear on leadscrew

Leave a small gap, 0.010" or so, between

gear stem and the outer bearing

Motor

unit

Mounting

bracket

Figure 4 Align the motor and mounting bracket

POWER FEED OPTIONS

Servicing the power feed motors

There are two carbon brushes on each power feed mo-

tor. If removed for inspection, they should be replaced in

the same orientation. Replace both when worn down to

about 0.2”.

Suggested procedure

1. Remove all components from the left hand end of the lead-

screw, Figure 2.

2. Install the gear, with key, on the leadscrew, Figure 3. Leave

clearance between gear stem and the leadscrew outer

bearing. Tighten the set screw.

3. Attach the motor unit to the mounting bracket, Figure 4,

leaving the two M6 screws loose enough to allow the

bracket to slide fore and aft relative to the motor (slots in

the head casting).

4. Set the mounting bracket against the left hand end of the

table. Position the motor so that, looking from below, the

small motor gear is aligned with the gear on the leadscrew,

100% meshing. Tighten the two M6 screws enough to pre-

vent accidental repositioning, then set the motor vertically

on the bench.

5. For accurate alignment of the two gears — this is import-

ant — the mounting bracket must be at right angles to

the motor axis. This can be approximated by aligning the

bracket with the motor head casting (use a depth gauge,

as Figure 4, or other means). Proper alignment minimiz-

es gear noise!

6. With the assembly back in place against the mill table,

check again for mesh. Readjust if necessary, then fully

tighten the M6 screws.

7. Position the motor/bracket assembly centrally relative to

the leadscrew gear — small gear directly in line above the

larger gear. Mark the table to show the two bracket slot

locations, Figure 5.

8. Drill and tap M8 holes in the two locations. Install the two

M8 screws and washers supplied.

Loading...

Loading...