30

PM-833TV 4-13-21V1.indd Copyright © 2021 Quality Machine Tools, LLC

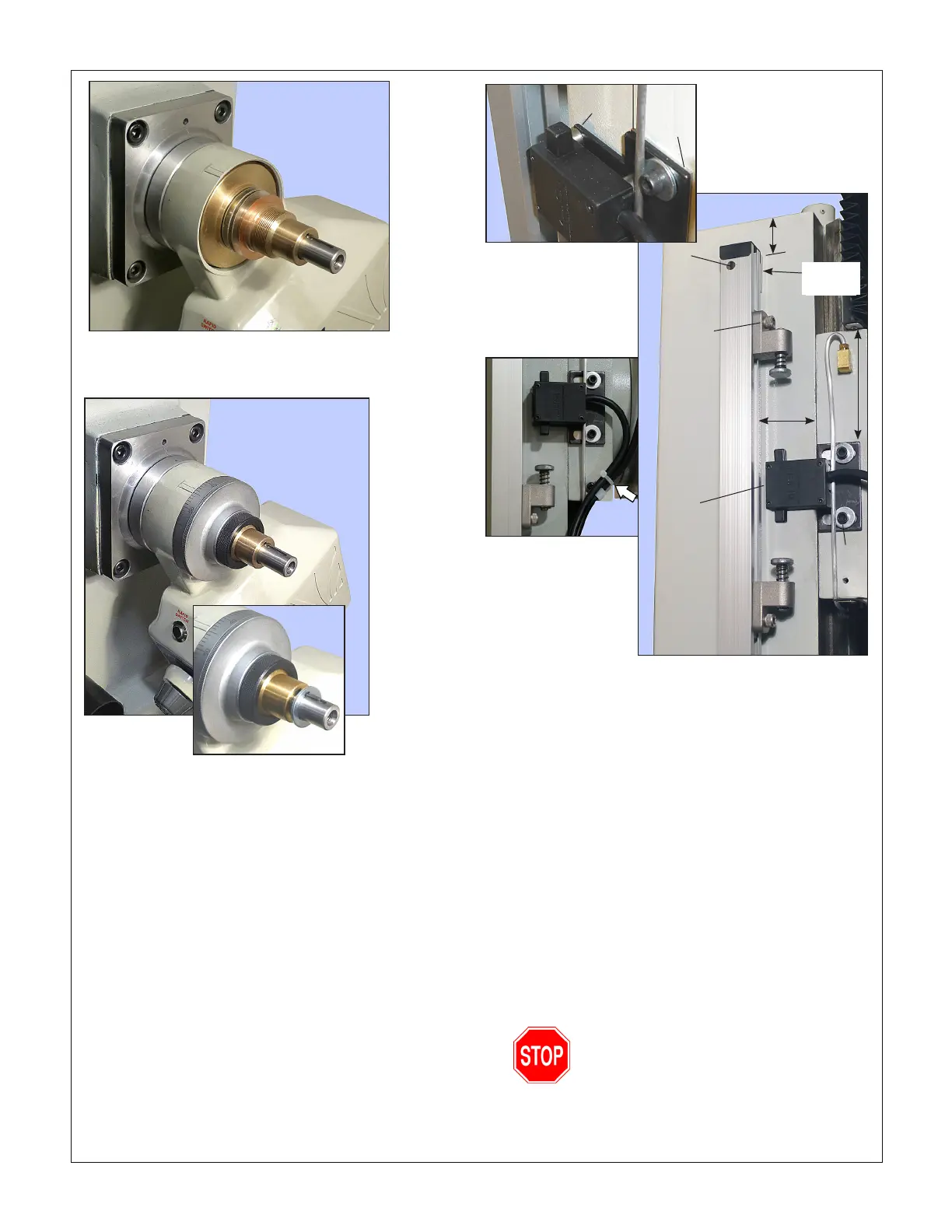

Figure 12 Dial re-installed

The spacer washer, inset, is for clearance be-

tween the crank handle and the motor body.

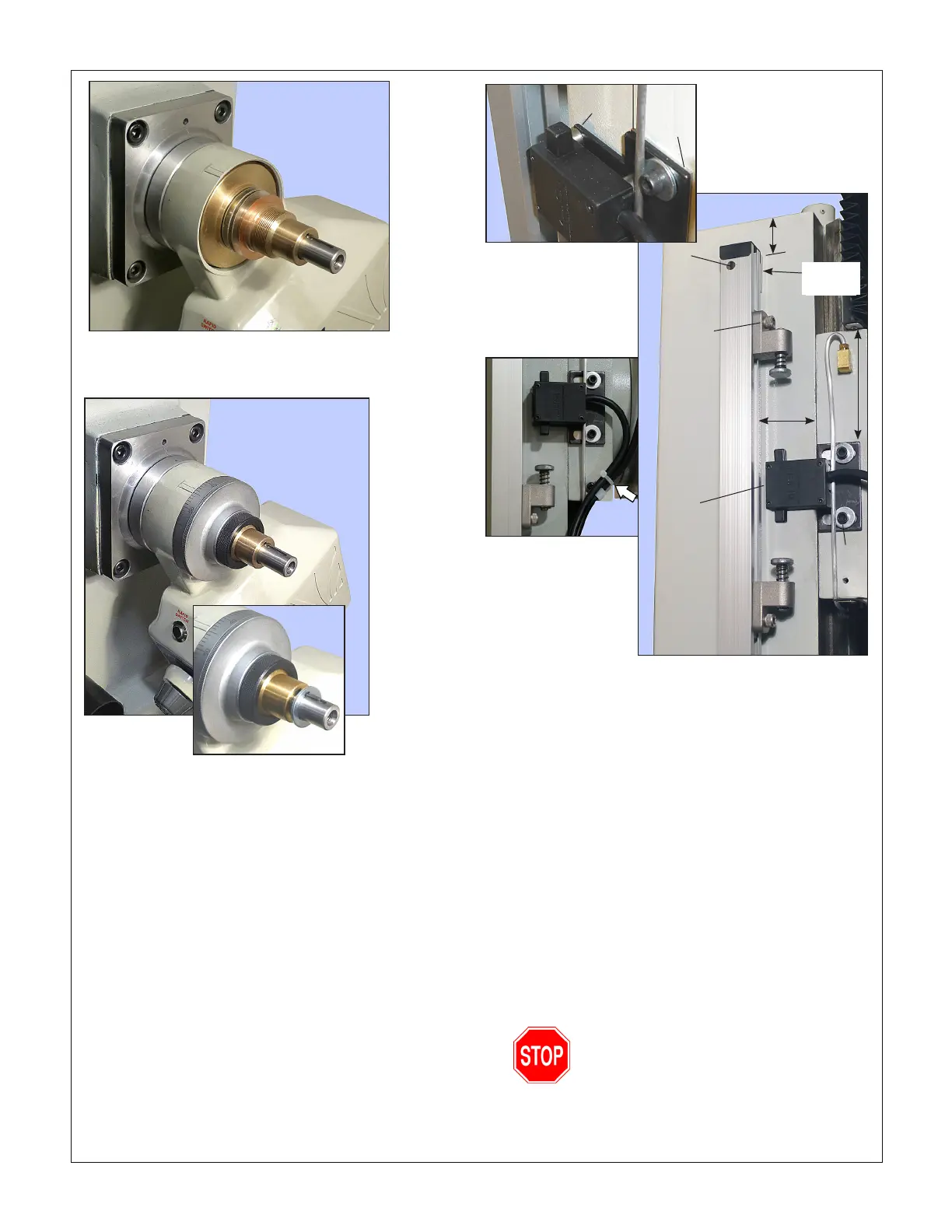

INSTALLING THE FEED STOPS

Figure 13 shows a suggested installation. The dimensions are

not critical.

Suggestion Cast iron powder gets everywhere! Before drill-

ing, protect all surfaces in the vicinity with taped-on scrap pa-

per. Before through-drilling into the column, remove: 1. The

accordion-pleated top cover, and; 2. The heavy nitrile cover

from the underside of the headstock, draping it forward over

the table. Protect the Z axis leadscrew, etc., before drilling and

tapping. Clean up with a vacuum.

1. Drill holes for M5 screws at top and bottom of the extrusion,

with oversize holes on the outer surface large enough for

the screw heads.

2. (Optional) In the installation shown in the photographs, the

limit switch mounting plate was shimmed by a 3 x 1-1/2"

aluminum plate 1/16" thick, drilled for two M6 screws. This

holds the mounting plate clear of the column, and also

Figure 13 Feed stop assembly

serves as a template for drilling the headstock.

3. To allow room for the aluminum oil pipe under the limit

switch cable, the limit switch was installed on 1/4" thick

stando bushings, Figure 13 inset. This called for longer

M3 screws than those supplied.

4. For better alignment of the limit switch actuators and the

feed stops, the extrusion was installed on 1-1/4" square

1/4" thick aluminum stando plates at top and bottom.

5. The lower inset, Figure 13, shows the limit switch cable tied

to the power cable.

6. For easier adjustment, the hex head 5/16-18 clamp screws

were replaced by socket head cap screws.

7. With the headstock at mid-travel, clamps loosened, pow-

er up the unit. Set the direction lever to UP, followed by

DOWN. Test the stop switches by applying light nger pres-

sure to the limit switches. If the headstock is moving down,

for instance, pressure on the lower actuator should stop

the motor.

Allow the motor and headstock to stop

moving before changing direction

1-1/2"

1.9"

M6

M5

5/16-18

clamp

screw

Limit

switch

4"

1/4" thick

stando

Stando

bushing

1/16"

shim

plate

Figure 11 Large shim washers on brass gear stem

Five washers were used on the sample machine: 3 x

0.024", 0.008" and 0.004".

Loading...

Loading...