V1.0 PROCUT 30A Digi Plus Plasma Cutter 9085754

Visit www.princessauto.com for more information 19

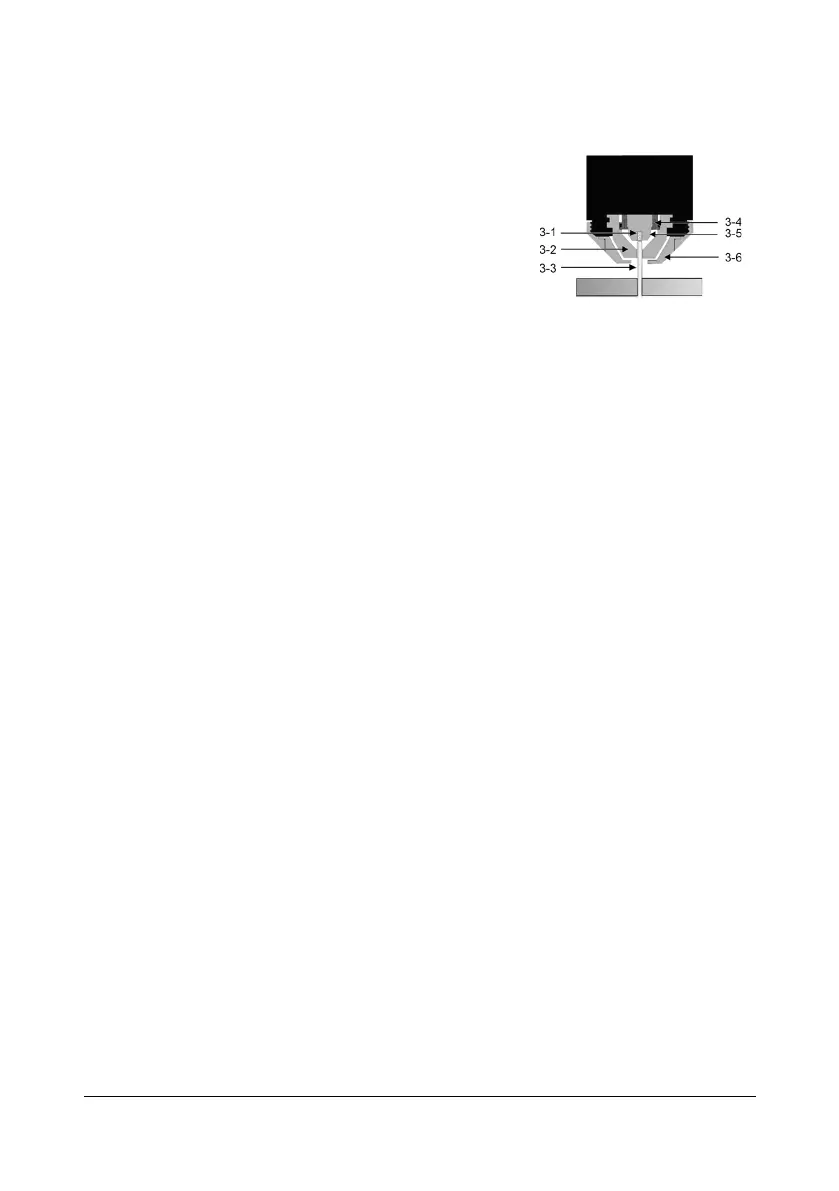

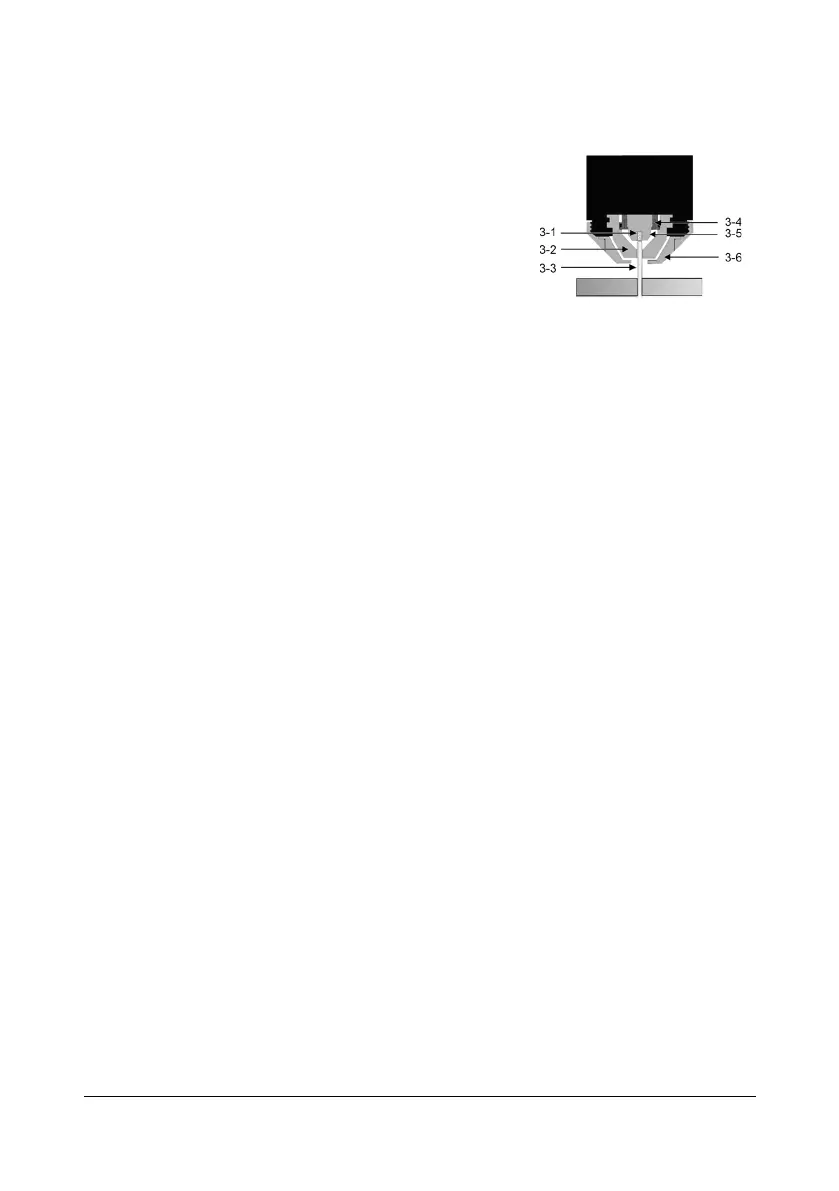

AIR PLASMA CUTTING TECHNOLOGY

A plasma cutter operates by passing an electric arc

from an electrode (Fig. 3-5) through a gas such as

nitrogen, air, argon or oxygen that is forced

through the air diffuser (Fig. 3-4) then a

constricted nozzle (Fig. 3-2). The shield cup

contains and directs the initial air/gas (Fig. 3-6).

The gas temperature is raised until it becomes

superheated plasma (Fig. 3-3). The plasma cuts

through the metal while carrying the electrical charge. The charge transfers to

the metal and ground cable, completing the electrical circuit.

The electrode has an insert of tough high conductive material such as

hafnium and cerium (Fig. 3-1). The nozzle and electrode require periodic

replacement due to erosion with use. Clean, dry air improves the lifespan of

the electrodes and nozzle. A plasma air filter is recommended.

OVER-VOLTAGE

This equipment has an automatic voltage compensation function, which

enables the unit to maintain the voltage within the given range. In case

that the input voltage or amperage exceeds the stipulated value, it is

possible to damage the equipment’s components. Please ensure your

primary power supply is correct (See Specifications).

DUTY CYCLE

The cutting unit’s duty cycle rating defines how long the operator can cut

before allowing the cutting unit to cool. The duty cycle is a percentage of a 10-

minute period. The cutting unit must cool for the remainder of the cycle.

If a cutting unit has a duty cycle rating of 60% at the rated output (see

Specifications), this means that the user can cut for 6 minutes and then rest

the welding unit for 4 minutes before using it again.

THERMAL PROTECTION

Constantly exceeding the duty cycle can damage the cutting unit. An internal

thermal protector will open when the duty cycle is exceeded, shutting OFF all

cutting unit functions except the cooling fan. Leave the cutting unit turned ON

with the fan running. The thermal protector will automatically reset and the

cutting unit will function normally again once it has cooled.

Wait at least another 10 minutes after the thermal protector opens before

resuming cutting. Starting before this additional time may result in a shortened

duty cycle.

Loading...

Loading...