9085754 PROCUT 30A Digi Plus Plasma Cutter V1.0

24 For technical questions call 1-800-665-8685

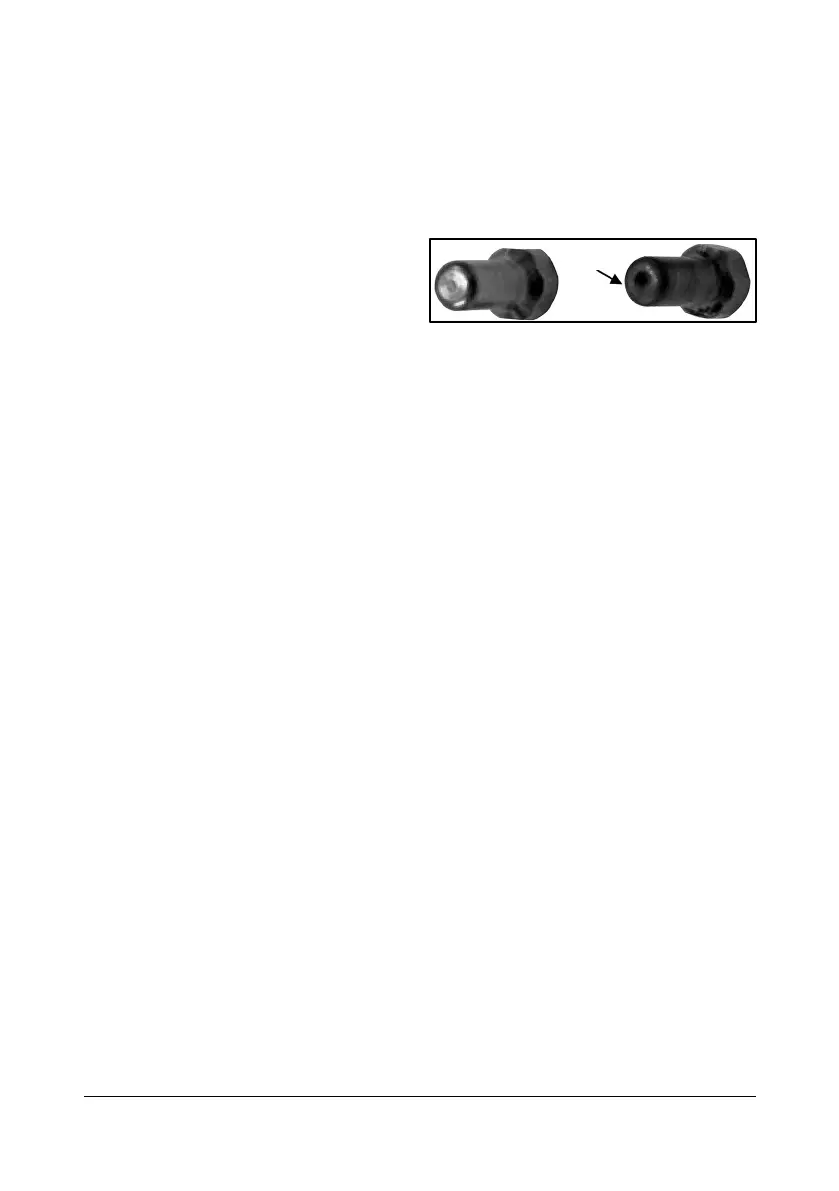

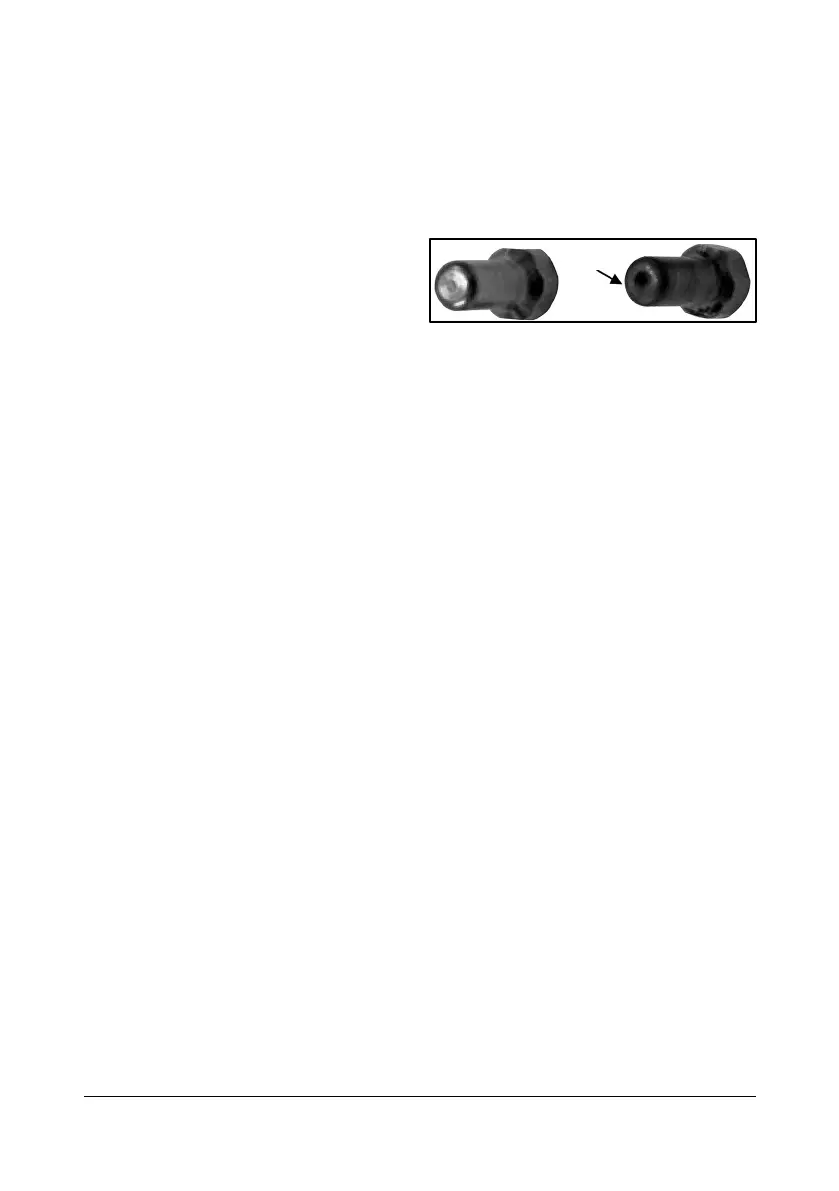

ELECTRODE CONDITION

A fixed gap is established between the electrode and the inside of the

cutting tip. Electrons arc across the gap, ionizing and super heating the air

creating the plasma stream. The electrode contains an insert in the end

made of a highly conductive material called hafnium. This insert erodes

with use and develops a pit in the

end of the electrode. As this pit

grows wider and deeper the quality

of the cut degrades (Fig. 14-1).

Replacement will be necessary.

AIR PRESSURE AND VOLUME

Air pressure, flow rate and air quality are critical to quality plasma cutting

and consumable life span (see Specifications).

The PROCUT 80 air pressure is pre-set at 75 PSI and requires a flow rate of 4.25

CFM (120 l/min). The volume capacity of your compressor is important, if you

have a small compressor with exactly the same CFM rating as the plasma cutter,

then the compressor will run continuously when you are plasma cutting.

A compressor with a CFM rating slightly higher than the plasma cutter would

be more appropriate. A compressor with 1.5 to 2 times the plasma cutter’s

requirement is better if you are doing a lot of cutting or cutting thick plate.

The same air consumption, but slower cut speeds equal a longer cut time.

AIR QUALITY

Good air quality is essential to quality plasma cutting and consumable life span.

The air from a compressor or gas cylinder should be dry and free of

particulate matter. Minimizing the moisture in the air supply is absolutely

critical to quality plasma cuts and longevity of consumable parts.

When moisture droplets enter the high temperatures in the torch’s plenum,

as much as 19,832°F, they immediately break down into oxygen and

hydrogen, which alters the normal chemical content of air in the torch. These

elements change the plasma arc, which alters the nozzle orifice’s shape and

causing the nozzle to wear away. This affects the cut quality in terms of edge,

dross formation, a square edge and edge smoothness.

As a minimum, be sure to drain the receiver (tank) on the air compressor

daily. Most air plasma systems have an on-board particulate filter and/or a

coalescing filter with an auto drain that will remove some moisture from

the air supply.

Loading...

Loading...