V1.0 PROCUT 30A Digi Plus Plasma Cutter 9085754

Visit www.princessauto.com for more information 23

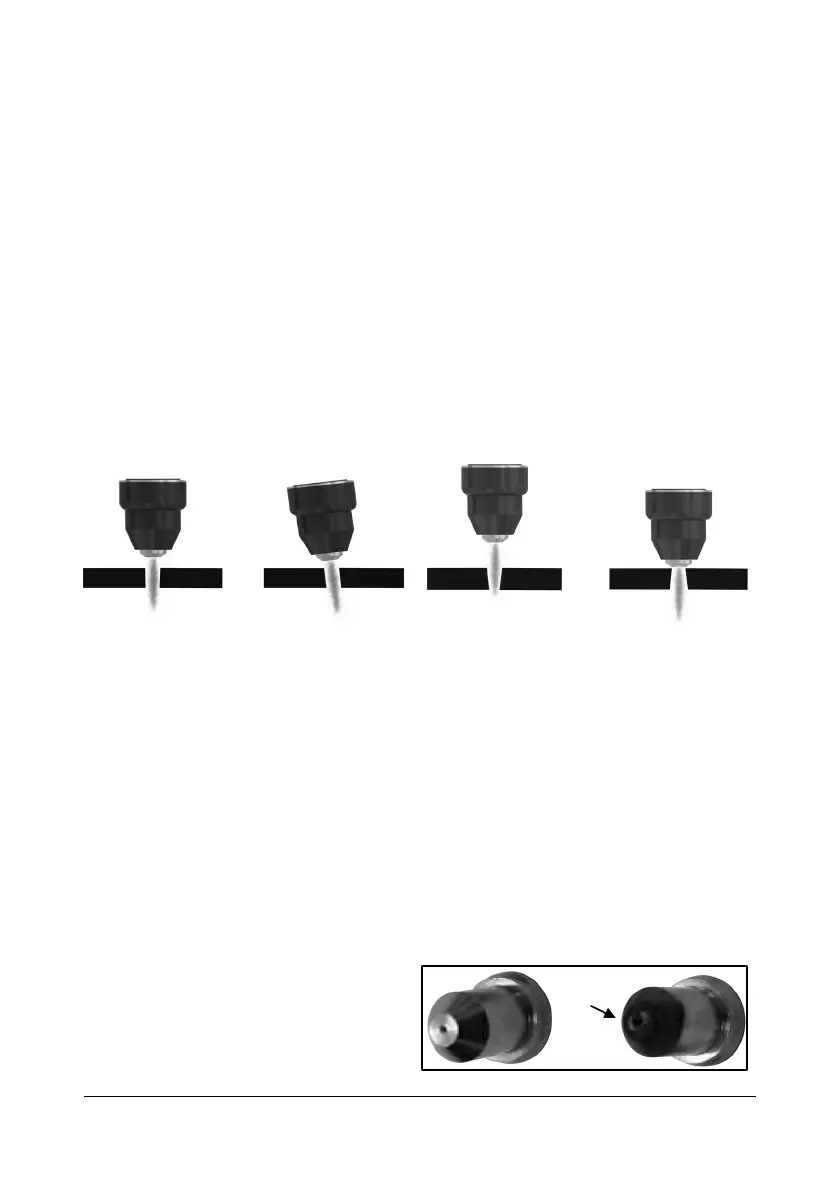

TORCH TIP HEIGHT & POSITION

The distance and position of the plasma torch cutting tip has an effect on the

quality of the cut and the extent of the cut’s bevel. The easiest way to reduce

bevel is by cutting at the proper speed and height for the material and

amperage that is being cut.

1. Correct torch height and square to the material. Minimum bevel &

equal bevel. Longest consumable life (Fig. 9).

2. Torch angled to the material. Unequal bevel, one side may be

excessively beveled (Fig. 10).

3. Torch height too high. Excessive bevel, plasma stream may not cut all

the way through the material (Fig. 11).

4. Torch height too low. Reverse bevel. Tip may contact the work and

short out or damage the tip (Fig. 12).

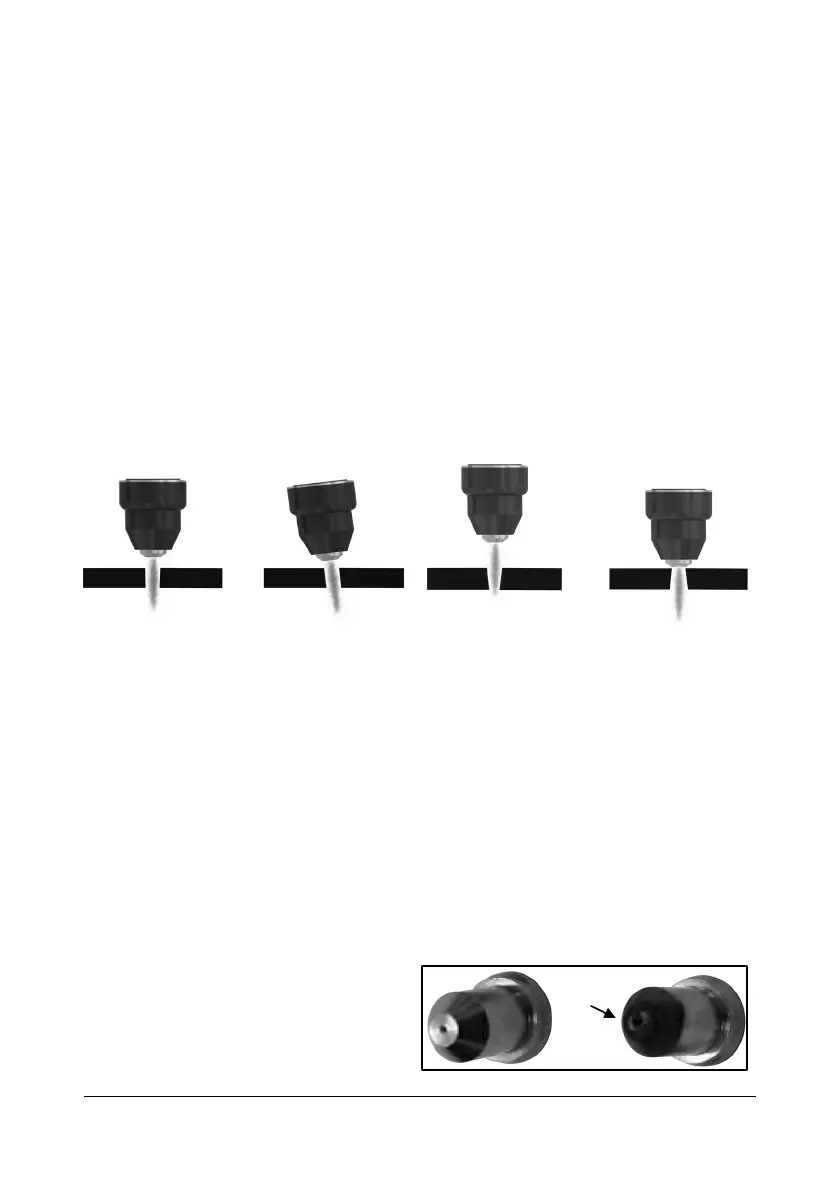

CUTTING NOZZLE TIP SIZE AND CONDITION

The cutting nozzle’s orifice focuses the plasma stream. It is important to use the

correct size tip for the amperage being used.

The size of the orifice dictates the width of the plasma stream. The low-amp

nozzle has a smaller orifice which maintains a narrow plasma stream at lower

settings for use on thin-gauge material.

A low-amp nozzle used with a high amperage setting will distort and damage

the nozzle beyond use. A high amperage nozzle used with lower amperage

will prevent the plasma stream from focusing correctly and create a wider cut

than intended.

The nozzle condition is critical to the quality of the cut result. A worn or

damaged nozzle orifice will produce a distorted plasma stream, resulting in a

poor cut quality (Fig. 13-1).

It is recommended to use a 3/64

in. tip with a setting of 0 to 40

amps and a 1/16 in. tip with a

setting of 40 to 80 amps.

Loading...

Loading...