V1.0 PROCUT 30A Digi Plus Plasma Cutter 9085754

Visit www.princessauto.com for more information 27

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for

electronic devices, batteries, oil or other toxic liquids.

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not

function properly or parts are missing. If unable to do so, have a qualified

technician service the tool.

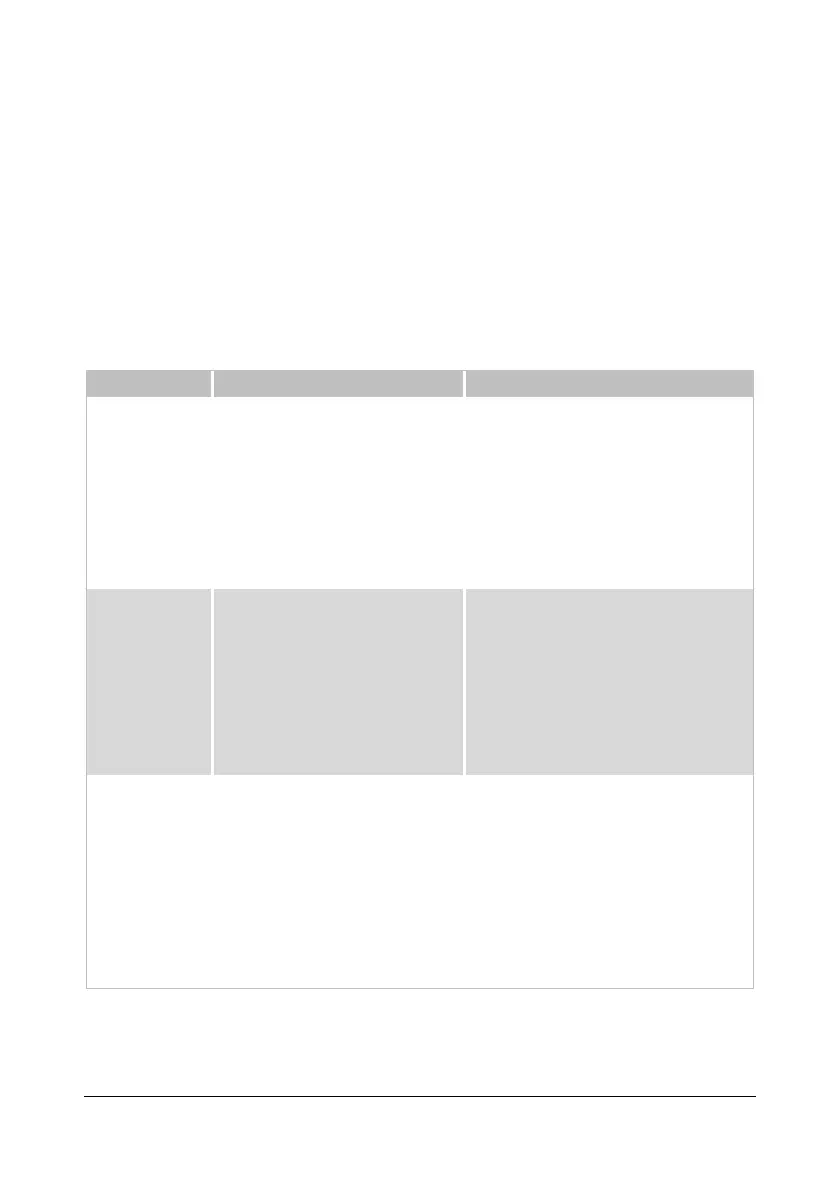

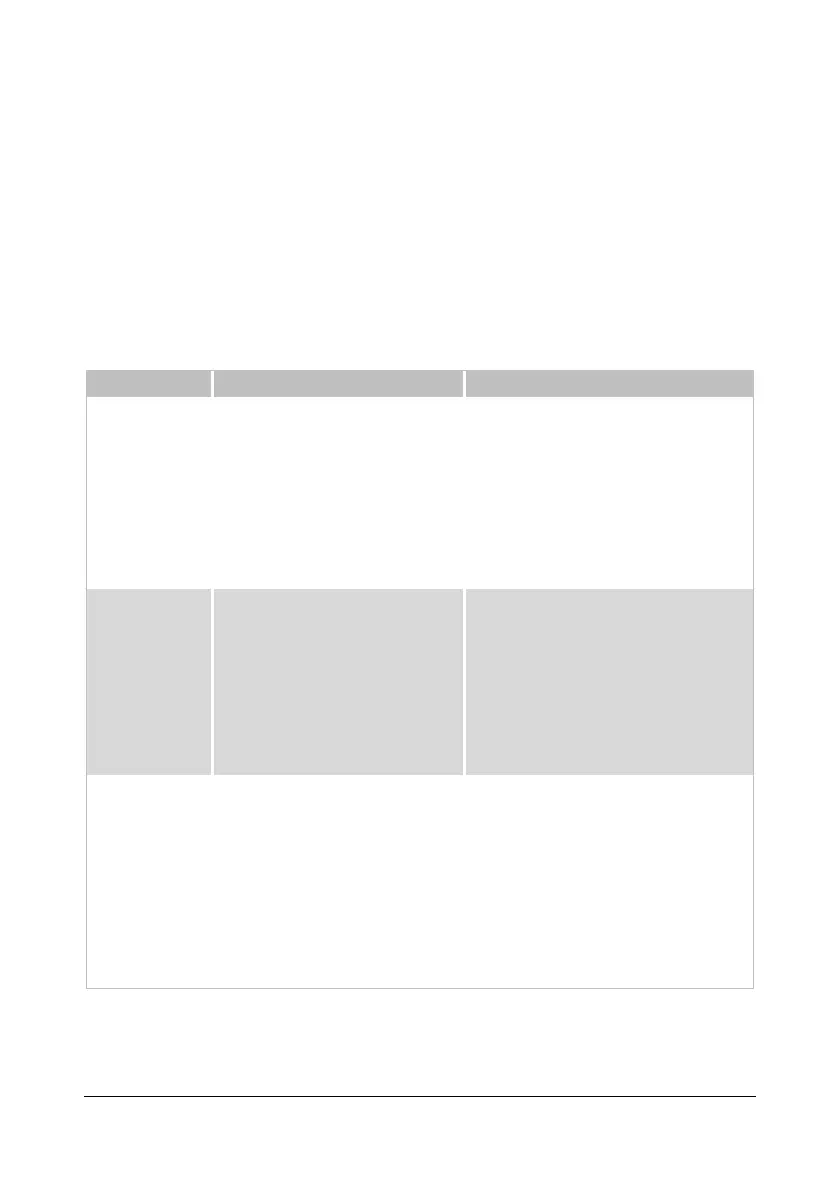

not stable

during

operation or

torch fails to

ignite.

1. Compressed air is too low

or too high.

2. Electrode of cutting torch

or nozzle is burnt.

3. Connection between

ground cable and

workpiece is poor.

4. Cutting speed is too slow.

2. Replace electrode or nozzle.

3. Connect firmly.

4. Adjust speed.

angle.

1. Nozzle or electrode is

burnt.

2. The installation position of

nozzle and electrode do

not match.

3. Cutting speed is too high.

4. Nozzle axis is not plumb

1. Replace nozzle or electrode.

2. Correctly install both.

3. Slow down cutting speed.

4. Adjust the torch angle.

wide, cut

quality is poor.

1. Cutting speed is too slow.

2. Torch’s electrode or nozzle

is burnt.

3. Cutting speed is too fast.

4. Wrong type of nozzle

used.

5. Excessive moisture or oil in

air source.

1. Accelerate cutting speed.

2. Replace electrode or nozzle.

3. Slow cutting speed. Review

4. Replace with a suitable nozzle.

5.

Select test air and aim torch

1/8 inch away from a clean

spot. If moisture or oil spots

appear, change filter or add

additional filters to air source.

Loading...

Loading...