14 © 2016 Proceq SA

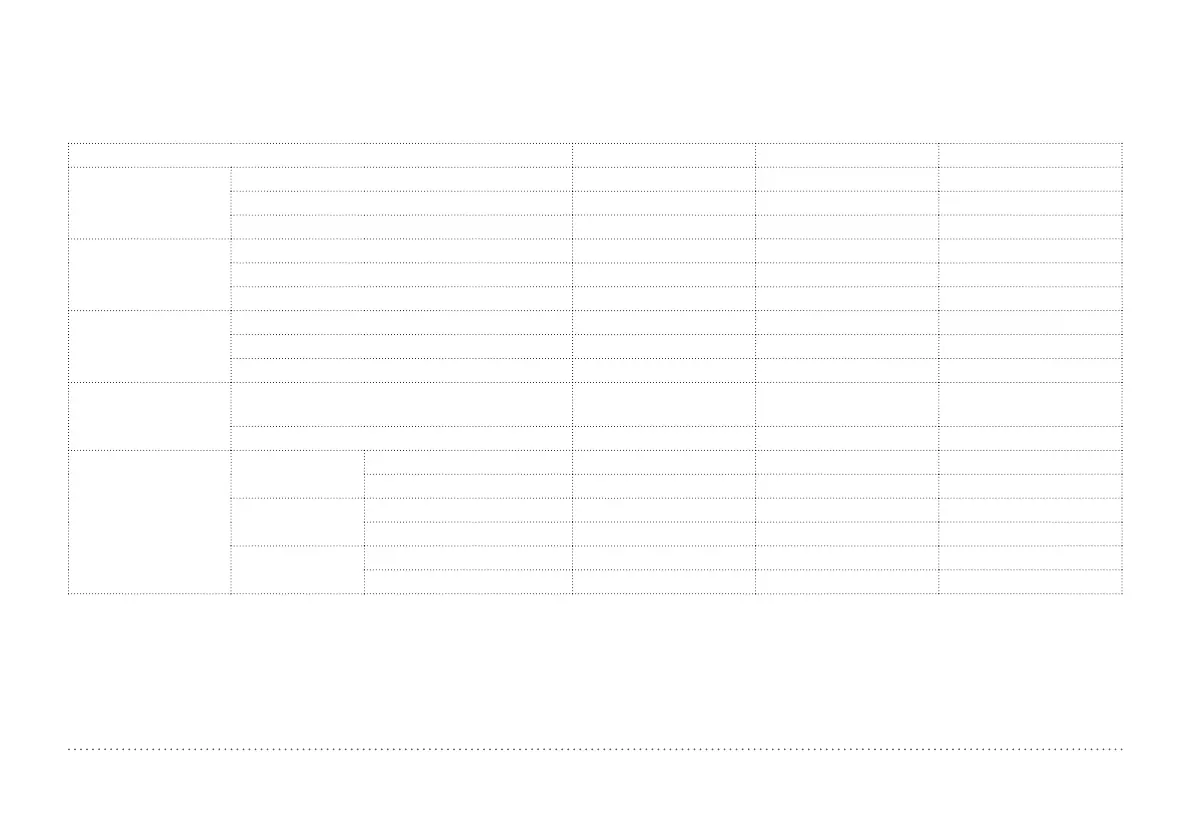

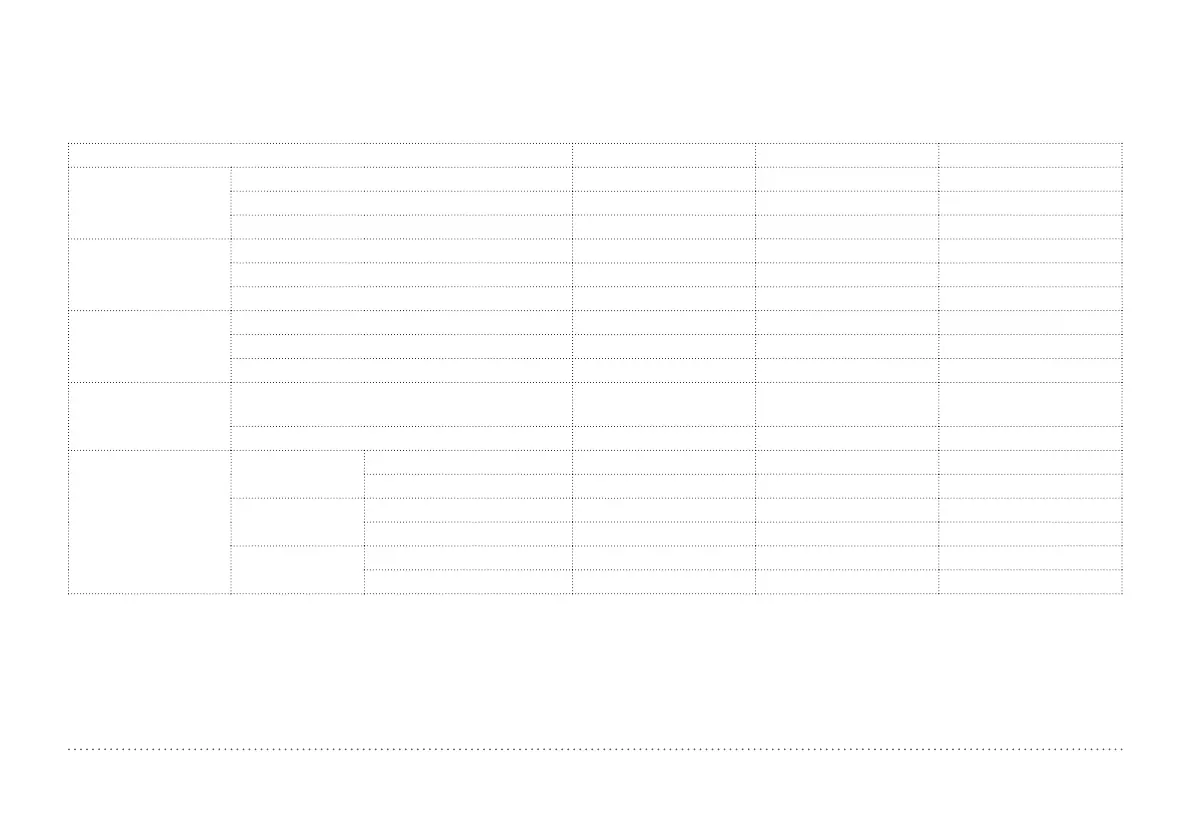

3.3.1.4 Test Conditions

To ensure proper hardness readings, the following conditions must be fulfilled. If one or more conditions are not met, the measurement result may be

significantly false.

Impact device type D/DC/DL/S/E G C

Surface

preparation

Roughness grade class ISO 1302

N7 N9 N5

Max. roughness depth R

t

(μm / μinch)

10 / 400 30 / 1200 2.5 / 100

Average roughness R

a

(μm / μinch)

2 / 80 7 / 275 0.4 / 16

Minimum sample

mass

Of compact shape (kg / lbs)

5 / 11 15 / 33 1.5 / 3.3

On solid support (kg / lbs)

2 / 4.5 5 / 11 0.5 / 1.1

Coupled on plate (kg / lbs)

0.05 / 0.2 0.5 / 1.1 0.02 / 0.045

Minimum sample

thickness

Uncoupled (mm / inch)

25 / 0.98 70 / 2.73 15 / 0.59

Coupled (mm / inch)

3 / 0.12 10 / 0.4 1 / 0.04

Surface layer thickness (mm / inch)

0.8 / 0.03 0.2 / 0.008

Minimum space

Between indentation and sample edge

(mm/inch)

5 / 0.2 8 / 0.3 4 / 0.16

Between indentations (mm/inch) 3 / 0.12 4 / 0.16 2 / 0.08

Indentation size on

test surface

With 300 HV,

30 HRC

Diameter (mm / inch)

0.54 / 0.021 1.03 / 0.04 0.38 / 0.015

Depth (μm / μinch)

24 / 960 53 / 2120 12 / 480

With 600 HV,

55 HRC

Diameter (mm / inch)

0.45 / 0.017 0.9 / 0.035 0.32 / 0.012

Depth (μm / μinch)

17 / 680 41 / 1640 8 / 2560

With 800 HV,

63 HRC

Diameter (mm / inch)

0.35 / 0.013 0.30 / 0.011

Depth (μm / μinch)

10 / 400 7 / 280

Table 1: Leeb Test Piece Requirements

Loading...

Loading...